Additive of Co-Ni alloy electroplating solution for electroplating

An alloy electroplating solution and additive technology, applied in the field of electroplating process, can solve the problems of complex electroplating process, prone to cracks, potential corrosion, etc., and achieve the effects of inhibiting abnormal deposition, improving bonding force, and strong deep plating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

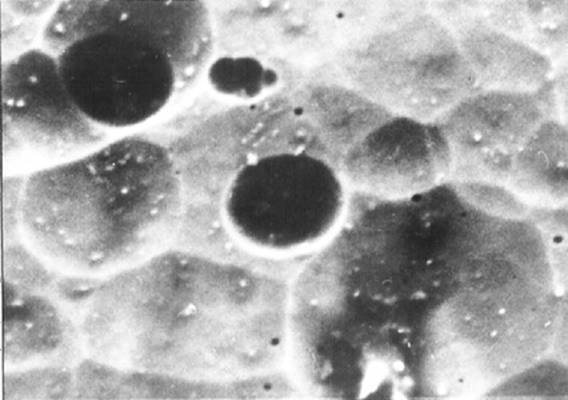

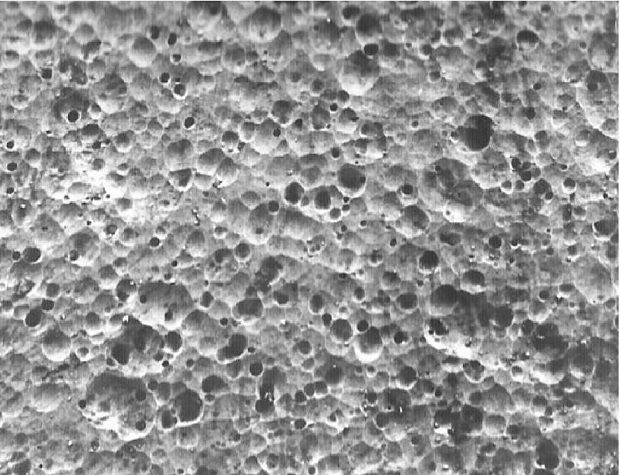

Image

Examples

Embodiment 1

[0075] A surface treatment method for a crystallizer copper plate, characterized in that the copper plate is a chromium-zirconium copper alloy, and the chromium-zirconium copper alloy undergoes the following steps: (1) pretreatment; (2) alkaline electrochemical corrosion treatment; ( 3) High-temperature annealing and reduction, wherein the copper plate of the crystallizer is used as the working electrode, the inert graphite carbon rod is used as the counter electrode, and the positive and negative electrodes can be controlled to reversing the power supply during the alkaline washing electrochemical corrosion treatment process.

[0076] (1) The pretreatment is mechanical grinding-oil removal and degreasing-hot water washing-cold water washing-acid activation-alkali washing-water washing, the mechanical grinding is grinding with 2000 mesh sandpaper, and the oil removal and degreasing is: 25g / LNa 2 CO 3 , 10g / LNaOH, 50g / LNa 3 PO 4 . 12H 2 O, 7g / LNa 2 SiO 3 , temperature 70 ...

Embodiment 2

[0091]A surface treatment method for a crystallizer copper plate, characterized in that the copper plate is a chromium-zirconium copper alloy, and the chromium-zirconium copper alloy undergoes the following steps: (1) pretreatment; (2) alkaline electrochemical corrosion treatment; ( 3) High-temperature annealing and reduction, wherein the copper plate of the crystallizer is used as the working electrode, the inert graphite carbon rod is used as the counter electrode, and the positive and negative electrodes can be controlled to reversing the power supply during the alkaline washing electrochemical corrosion treatment process.

[0092] (1) The pretreatment is mechanical grinding-oil removal and degreasing-hot water washing-cold water washing-acid activation-alkali washing-water washing, the mechanical grinding is grinding with 2000 mesh sandpaper, and the oil removal and degreasing is: 25g / LNa 2 CO 3 , 10g / LNaOH, 50g / LNa 3 PO 4 . 12H 2 O, 7g / LNa 2 SiO 3 , temperature 75 ...

Embodiment 3

[0109] A surface treatment method for a crystallizer copper plate, characterized in that the copper plate is a chromium-zirconium copper alloy, and the chromium-zirconium copper alloy undergoes the following steps: (1) pretreatment; (2) alkaline electrochemical corrosion treatment; ( 3) High-temperature annealing and reduction, wherein the copper plate of the crystallizer is used as the working electrode, the inert graphite carbon rod is used as the counter electrode, and the positive and negative electrodes can be controlled to reversing the power supply during the alkaline washing electrochemical corrosion treatment process.

[0110] (1) The pretreatment is mechanical grinding-oil removal and degreasing-hot water washing-cold water washing-acid activation-alkali washing-water washing, the mechanical grinding is grinding with 2000 mesh sandpaper, and the oil removal and degreasing is: 25g / LNa 2 CO 3 , 10g / LNaOH, 50g / LNa 3 PO 4 . 12H 2 O, 7g / LNa 2 SiO 3 , temperature 80 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com