Method for regulating and controlling interaction between metal nanoparticles and carrier by plasma

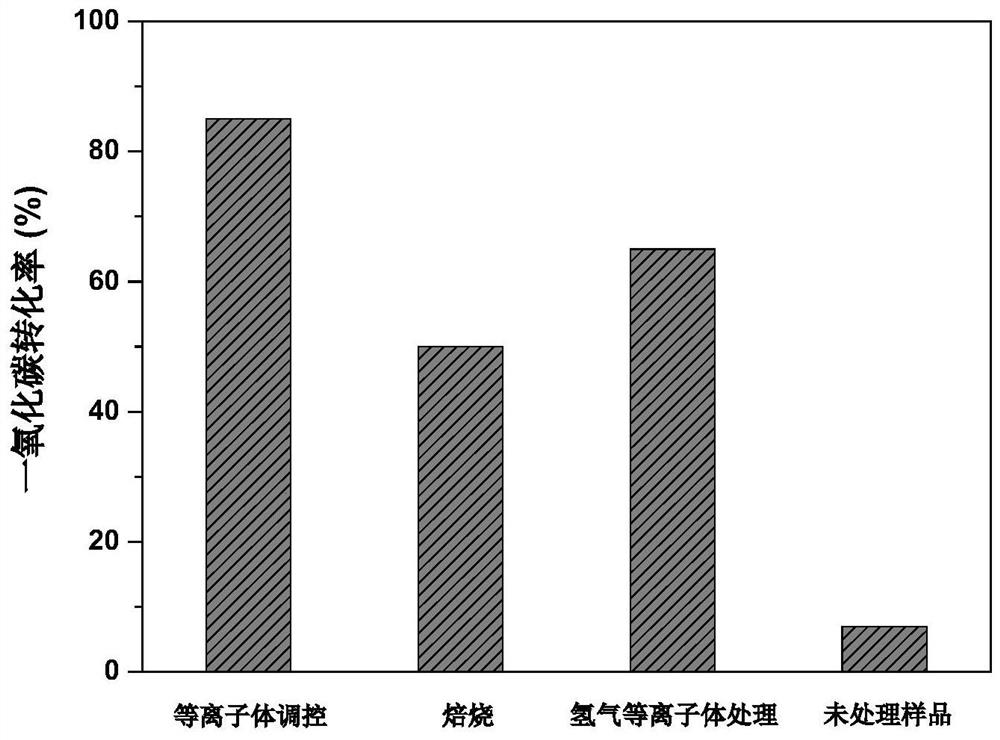

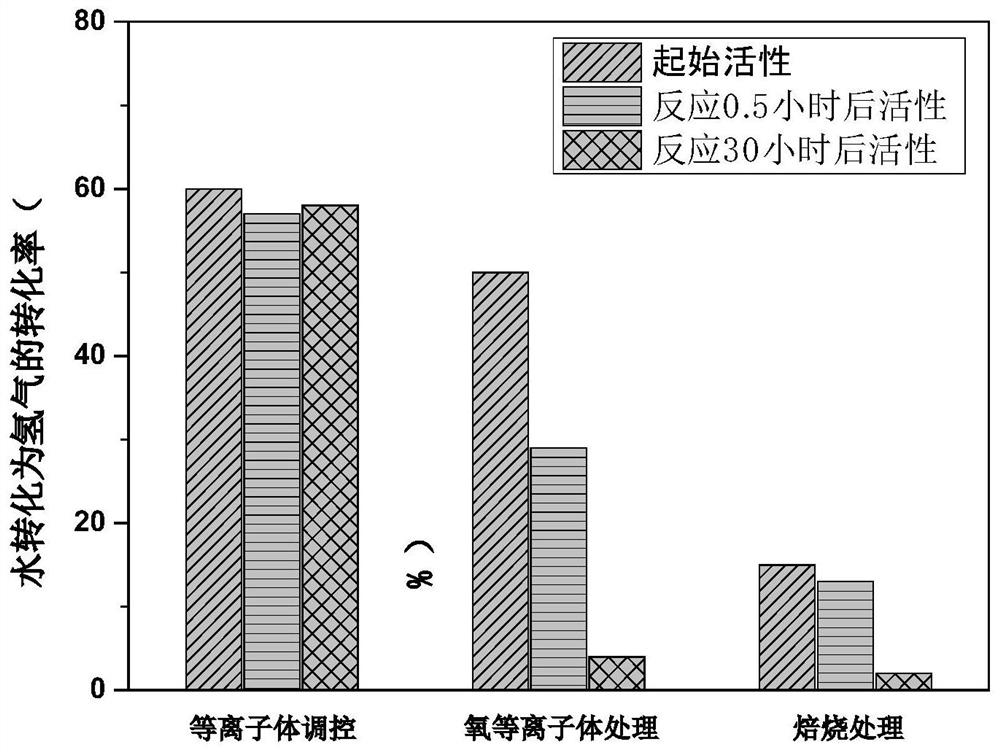

A technology of metal nanoparticles and plasma, which is applied in separation methods, non-metallic elements, and dispersed particle separation, etc., can solve problems such as poor catalyst stability, achieve the effects of ensuring catalyst activity, convenient operation, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

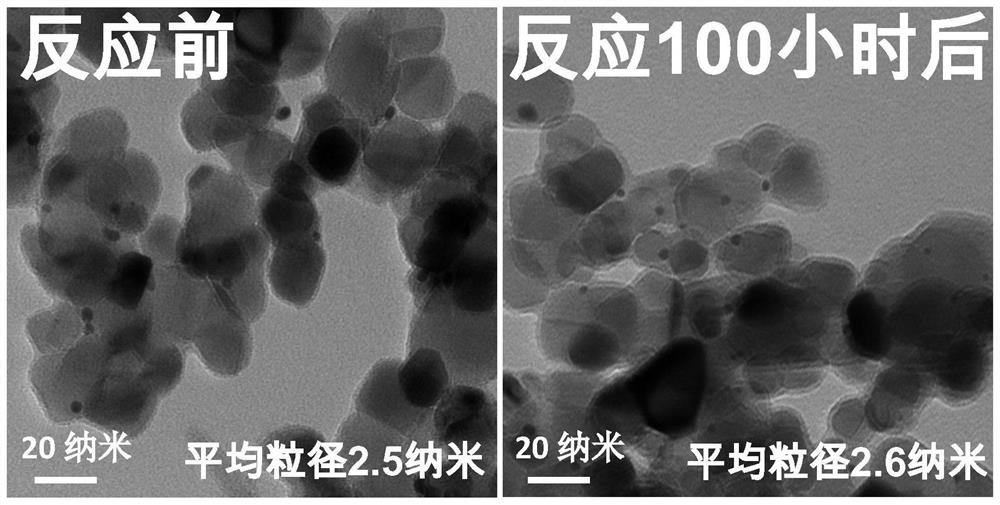

Examples

Embodiment 1

[0037] A method for plasma regulating the interaction between metal nanoparticles and carriers, comprising the following steps:

[0038] a. Weigh 5g of chloroauric acid and dissolve it in 500ml of water to prepare 2.4×10 -2 mol / L chloroauric acid standard solution (gold precursor standard solution), weigh 10mg platinum chloride and dissolve it in 100mL deionized water to prepare 3.77×10 -3 mol / L platinum nitrate solution (platinum precursor solution), weigh 1g sodium hydroxide and dissolve in 50mL deionized water to prepare 0.5mol / L sodium hydroxide solution;

[0039] b. Weigh 2gTiO 2 (Mixed crystals of rutile and anatase) were added to a beaker filled with 100mL of platinum nitrate and chloroauric acid solution (the volume ratio of the two was 1:1), and mixed evenly under the condition of 1000r / min, using 0.5mol / L Sodium hydroxide solution adjusts the pH value to 8 (greater than TiO 2 Isoelectric point 6), the sample is mixed for 1 hour, so that the gold platinum precursor...

Embodiment 2

[0048] a. Weigh 2g of chloroauric acid and dissolve it in 200ml of water to prepare 2.4×10 -2 The chloroauric acid standard solution (gold precursor standard solution) of mol / L;

[0049] b. Weigh 2gCeO 2 Add the powder into a beaker containing 20mL of chloroauric acid solution with a certain concentration to impregnate the carrier with the chloroauric acid solution, and let the sample stand for 12 hours to fully load the gold precursor on CeO 2 ;

[0050] c. Alternate washing of alkaline solution and neutral solution (deionized water) is carried out to the obtained impregnated product, and the washing is repeated more than two times until 2.0×10 -2 mol / L AgNO 3 Titrate the solution until no precipitation occurs; the pH of the alkaline solution must meet ≥8 (higher than CeO 2 The isoelectric point of the powder is 7.6); after each washing, ultrasonic treatment is required for 10 minutes, followed by centrifugation for 10 minutes to obtain a solid sample;

[0051] d. Dry th...

Embodiment 3

[0058] a. Weigh 1g palladium chloride and dissolve it in 200ml water to prepare 3×10 -2 The nitric acid standard solution (palladium precursor standard solution) of mol / L, takes by weighing 1g sodium hydroxide and is dissolved in 50ml deionized water and prepares the sodium hydroxide solution of 0.5mol / L;

[0059] b. Weigh 2g γ-Al 2 o 3 Add it into a beaker containing 60ml of palladium chloride solution, mix evenly under the condition of 1000r / min, use 0.5mol / L sodium hydroxide solution to adjust the pH value to 9, mix the sample for 1 hour, and precipitate the palladium precursor on γ-Al 2 o 3 surface;

[0060] c. Use sodium hydroxide solution with a pH value of 9 and deionized water to alternately wash the deposited and precipitated samples, and wash more than 2 times until 2.0×10 -2 mol / L AgNO 3 No precipitation occurred in the titration of the solution, and the washing solution was filtered to obtain a solid sample;

[0061] d. Dry the obtained solid sample in an ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com