Lithium ion battery negative electrode material, negative plate and battery

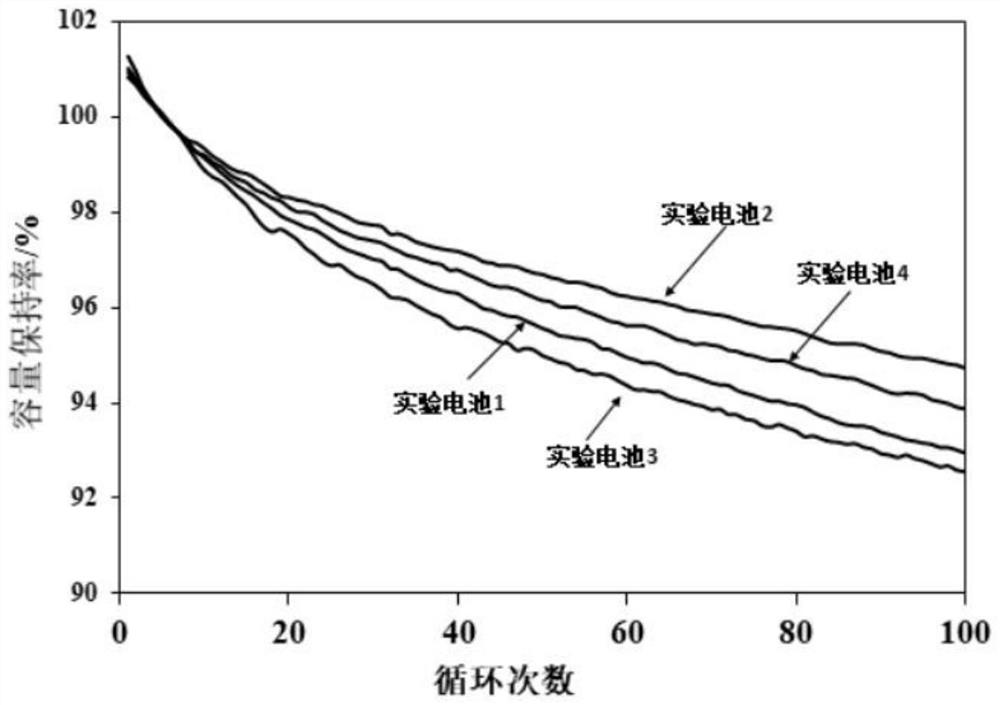

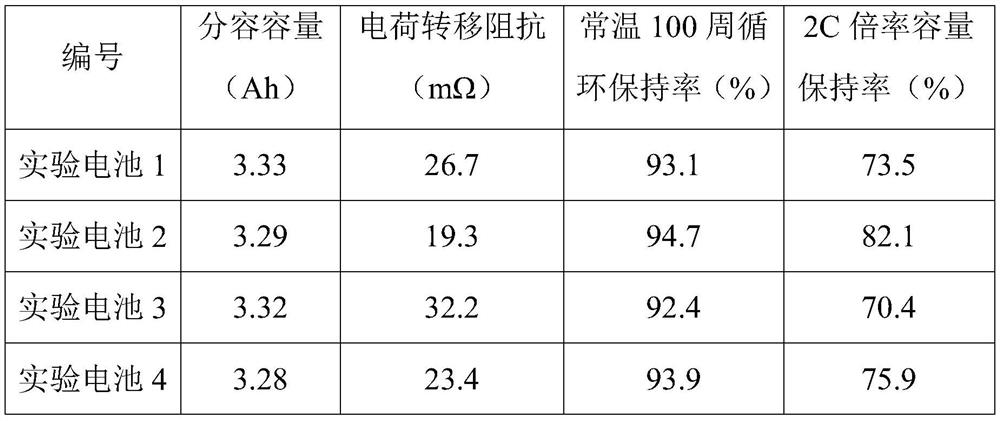

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of reducing the effective active material content of the negative plate, high production cost, short cycle life, etc., to improve the cycle capacity retention rate , Improve wetting and holding capacity, reduce the effect of battery impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of pseudo-physalis seed gum, comprising the steps:

[0024] Weigh 500g of impurity-removed false physalis seeds and soak them in 2500g of deionized water, heat in a water bath to control the water temperature to be 60°C, extract for 60 min, and remove the false physalis seeds with 100-mesh filter gauze to obtain the filtrate, which is the false physalis glue 50g concentrated liquid was obtained by concentrating the original solution of pseudo-physalis colloid in a rotary evaporator at 60 °C, adding isopropanol to precipitate the pseudo-physalis colloid from the concentrated solution, collecting the precipitate, vacuum drying, and pulverizing to obtain a pseudo-acid Pulp Seed Gum 3.4g.

Embodiment 2

[0026] A preparation method of pseudo-physalis seed gum, comprising the steps:

[0027] Weigh 500g of impurity-removed false physalis seeds and soak them in 5000g of deionized water, heat in a water bath to control the water temperature to 90°C, extract for 30 minutes, and remove the false physalis seeds with 100-mesh filter gauze to obtain the filtrate, which is the false physalis glue 500g of concentrated solution was obtained by concentrating the original solution of pseudo-physalis colloid in a rotary evaporator at 60°C, adding isopropanol to precipitate the pseudo-physalis colloid from the concentrated solution, collecting the precipitate, vacuum drying, and pulverizing to obtain a pseudo-acid Pulp Seed Gum 3.8g.

Embodiment 3

[0029] A lithium ion battery, the preparation method of which comprises the following steps:

[0030] a. Preparation of positive electrode sheet: Mix the positive active material NMC811 ternary material, the conductive agent acetylene black, and the binder polytetrafluoroethylene according to the weight ratio of 95:2.5:2.5, add N-methylpyrrolidone, and fully stir and mix A uniform positive electrode slurry is uniformly formed, uniformly coated on a 15 μm thick aluminum foil, and a positive electrode sheet is obtained after drying;

[0031] b, preparation of negative electrode sheet: the silicon carbon composite material (that is, the negative electrode active material), the conductive agent acetylene black, the pseudo-acid pulp seed colloid prepared in Example 1 and the binder SBR are 97.5:0.5:1 according to weight ratio: 1 Mix well, add deionized water, fully stir and mix to form a uniform negative electrode slurry, evenly coat it on 8μm thick copper foil, and dry to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com