3D integrated structure of load point power supply module and assembly process

A point-of-load power supply and assembly process technology, which is applied to the assembly of printed circuits with electrical components, output power conversion devices, printed circuits connected with non-printed electrical components, etc., can solve the problem of reducing the power density of power modules and reducing the module Internal space utilization, reducing space utilization and other issues, to achieve the effect of reducing wiring parasitic impedance, improving heat dissipation efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

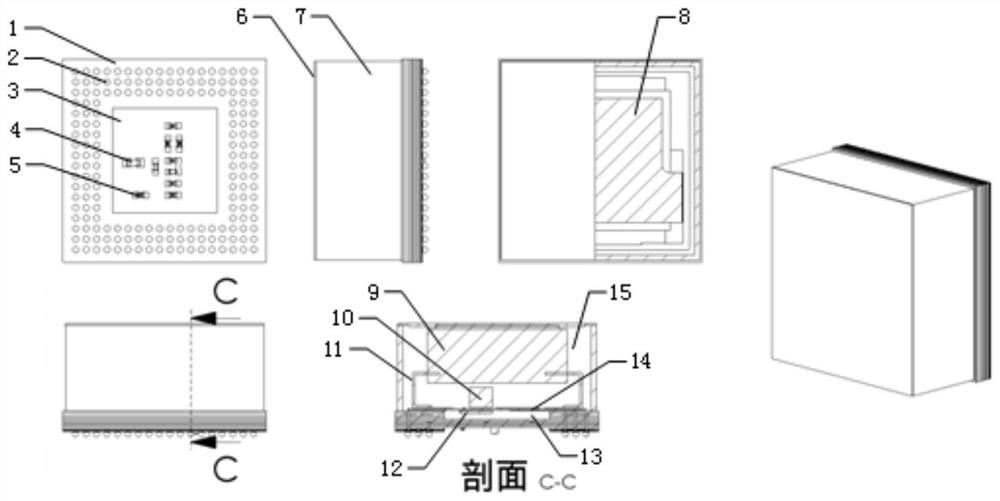

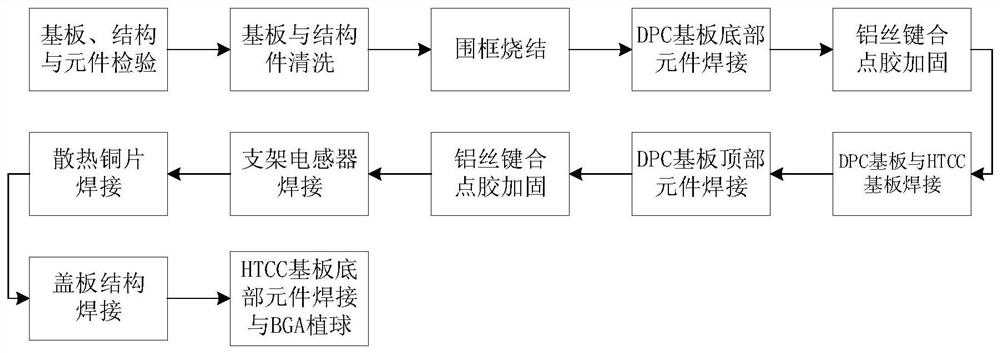

[0067] The 3D integrated structure and assembly process for this power module are now described in detail:

[0068] 1. Bracket inductor design: custom-made chip inductors, the inductor body is manufactured by traditional integrated surface-mount inductor technology, and the body size is 17×17×6.5mm 3 ; Increase the pin length of the coil spot welding frame to ensure that the distance between the bottom of the inductor body and the bottom of the pin bracket after co-firing is greater than 3mm.

[0069] 2. Ceramic substrate design: design DPC substrate dimensions 21.6×21.6×0.25mm 3 , the dielectric material is 90% Al 2 o 3 For the base material, the thickness of the metal layer is 70um; the devices on the DPC substrate adopt a double-sided layout method to reduce the wiring area. HTCC substrate dimensions 24.6×24.6×2.5mm 3 , the dielectric material is KCH90 substrate, and the thickness of the metal layer is 12um; the center of the TOP surface and BOTTOM surface of the HTCC s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com