Preparation method and oxygen reduction performance of semi-porphyrazine polymer

A technology for porphyrazines and polymers, which is applied in chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, chemical/physical processes, etc., can solve the problems of less research on hemiporphyrazine and the like, and achieve high yields High, time-saving, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

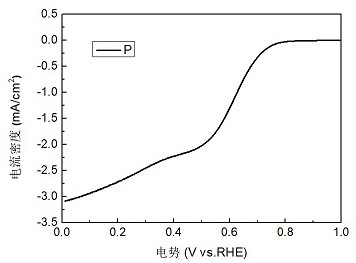

example 1

[0020] Add 300 mg of 1,2,4,5-tetracyanobenzene and 400 mg of 3,5-diamino-1,2,4-triazole according to the molar ratio of 1:2.4 into a tank containing 80 ml of ethylene glycol 100 ml round-bottomed flask, and then sonicated for 15 minutes to make it evenly dispersed in ethylene glycol, then put it into a microwave reactor, stir with a magnetic stirrer, then set the microwave power to 800 W, and the temperature was 180 ° C, and then heated under this condition for 1 h to obtain a brown product, and the solution was cooled to room temperature. Then add 40 mL (1 mol / L) of hydrochloric acid solution, sonicate for 10 minutes, and then centrifuge, and then wash twice with distilled water after all centrifugation. The obtained material was dried in a freeze dryer for 12 h, and the dried powder was ground in a mortar evenly, then put into a porcelain boat, and then the powder was pyrolyzed under an argon atmosphere with a gas flow rate of 50 mL / min. The calcination process was heated...

example 2

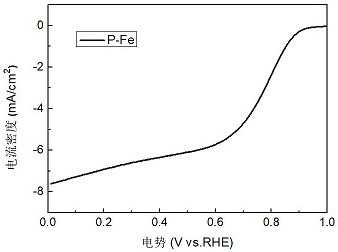

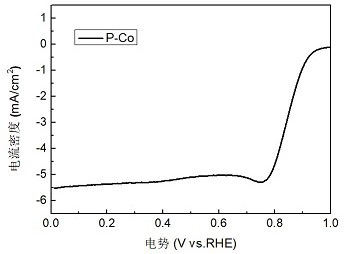

[0022] Add 300 mg of 1,2,4,5-tetracyanobenzene and 400 mg of 3,5-diamino-1,2,4-triazole according to the molar ratio of 1:2.4 into 60 ml of ethylene glycol 100 ml round bottom flask, and then sonicated for 15 minutes to make it evenly dispersed in ethylene glycol. Similarly, 481 mg of CoCl 2 6(H 2 O) or 328 mg of FeCl 3 Dissolved in 20 ml of ethylene glycol, then mixed the two solutions, then put the mixture into a microwave reactor, stirred using a magnetic stirrer, then set the microwave power to 800 W, the temperature was 180 °C, and then in Heating under this condition for 20 min gave a dark brown product, and the solution was cooled to room temperature. Then add 40 ml (1 mol / L) of hydrochloric acid solution, sonicate for 10 minutes, then centrifuge, and wash twice with distilled water after all centrifugation. The obtained material was dried in a freeze dryer for 12 h, and the dried powder was ground in a mortar until uniform, then put into a porcelain boat, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com