A molecular sieve production device

A production device and molecular sieve technology, applied in molecular sieve compounds, molecular sieves and alkali exchange compounds, inorganic chemistry, etc., can solve problems such as difficulty in discharging materials from production devices, affecting subsequent material ratios, kneader motor failures, etc., to reduce manual labor , convenient real-time monitoring and adjustment, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

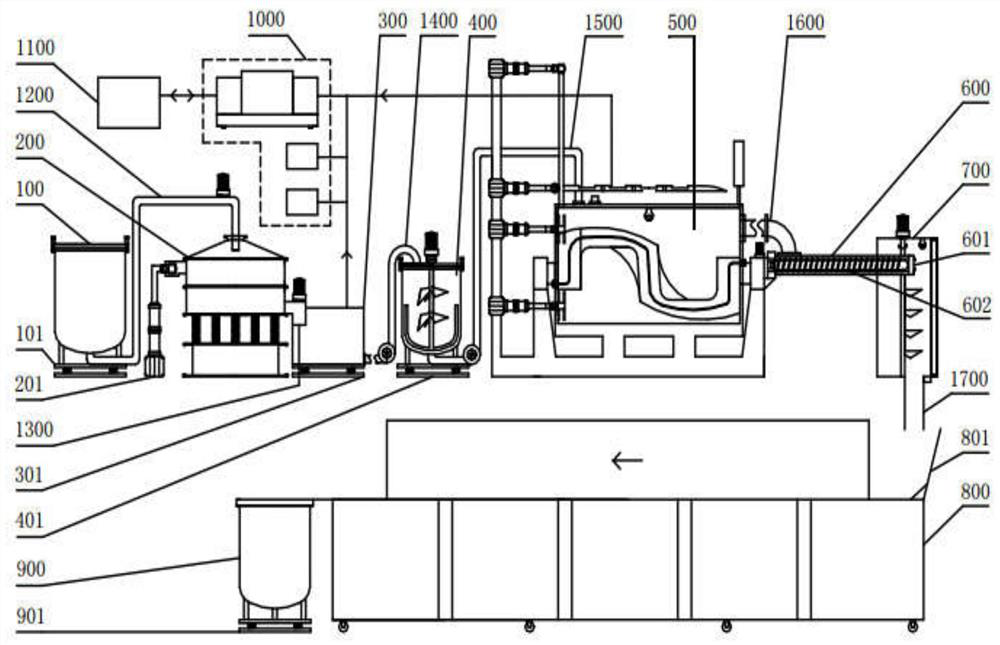

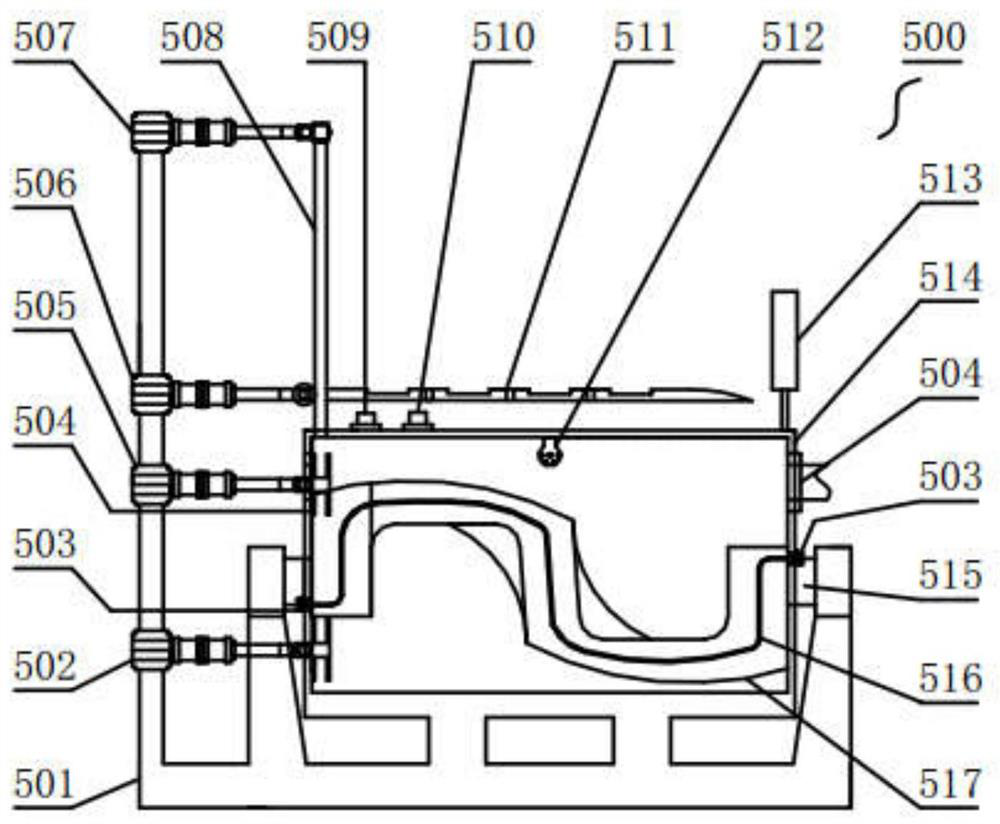

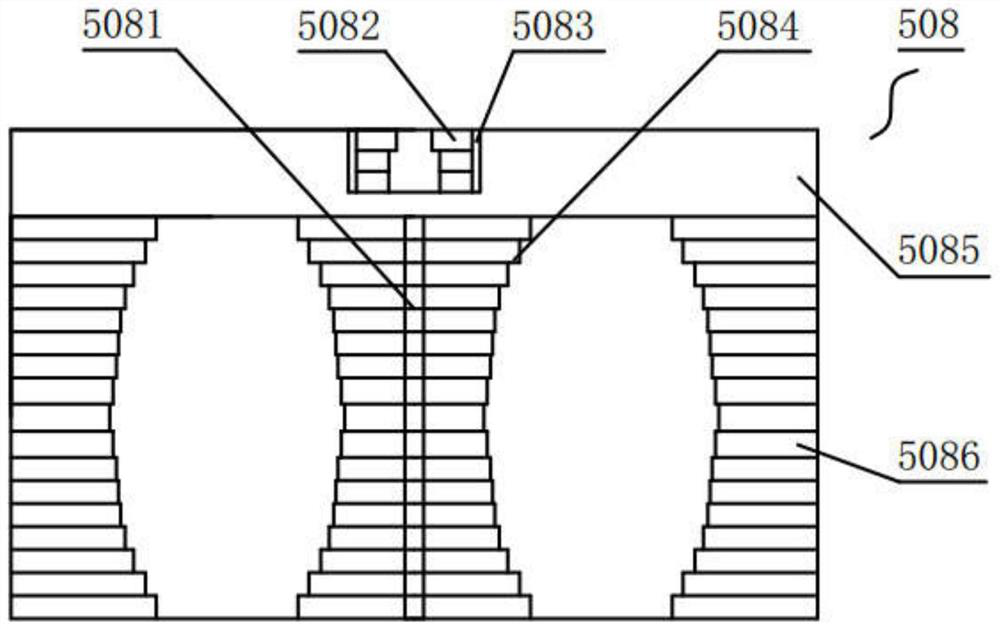

[0036] Such as figure 1 As shown, it is a structural schematic diagram of a molecular sieve production device provided by an embodiment of the present invention, including a raw material storage tank 100, a sieving instrument 200, a buffer tank 300, a mixing tank 400, a kneader 500, an extruder 600, a hot box 700, Oven 800, finished product tank 900, detection device 1000, control system 1100 and corresponding connecting pipelines and circuits.

[0037] The bottom of the raw material storage tank 100 transmits the material to the sieving apparatus 200 through the pipeline 1200 containing the pump. The upper side of the screen of the sieving apparatus 200 is connected with a telescopic rod, and the cover can be opened for inspection and maintenance through the telescopic rod. The lower end of the sieve mesh of the sieving apparatus 200 transmits the sieved material to the buffer tank 300 through the pump pipeline 1300 . The end of the buffer tank 300 away from the pump-contain...

Embodiment 2

[0067] Based on the structural schematic diagram of a molecular sieve production device in Example 1, this embodiment provides a method for preparing a molecular sieve, the steps of which include the following:

[0068] Step 1): Put the powder raw material into the raw material storage tank, and transfer it to the sieving machine to screen out the uniform powder with the required particle size.

[0069] Step 2): Collect the uniform powder obtained in the above step 1 in a buffer tank.

[0070] Step 3): Transfer the powder collected in the above step 2 to a mixing tank, and mix with high speed shearing to obtain fine powder.

[0071] Step 4): Mix the fine powder obtained in the above step 3 with the liquid material in a kneader to obtain a viscous material.

[0072] Step 5): extruding the viscous material obtained in the above step 4 through an extruder.

[0073] Step 6): Simultaneously dry and cut the molding material obtained in the above step 5 into a semi-dry product of t...

Embodiment 3

[0087] A kind of molecular sieve production device based on above embodiment 1, the method for Y-type molecular sieve production is provided, comprises the following steps:

[0088] Step 1): 100 parts of Y-type molecular sieve, 8 parts of stearate, 2 parts of plant powder, 0.7 part of F-127, Cu(NO 3 ) 2 Put 0.5 part into the raw material storage tank, and transfer to the sieving machine to screen out the uniform powder with the required particle size.

[0089] Step 2): The uniform powder is collected in the buffer tank.

[0090] Step 3): In the mixing tank, the blades are sheared at a speed of 4000 rpm to obtain fine powder.

[0091] Step 4): Mix the refined powder with 15 parts of methanol, 170 parts of ethanol, and 2 parts of OP-10 in a kneader. The kneading rod rotates at 120 rpm and kneads at room temperature for 1.5 h to obtain a relatively dilute material. After passing through the second kneader The temperature was raised to 75°C, the rotational speed of the kneadin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com