Preparation method of cellulose antibacterial material modified based on natural active component chlorogenic acid

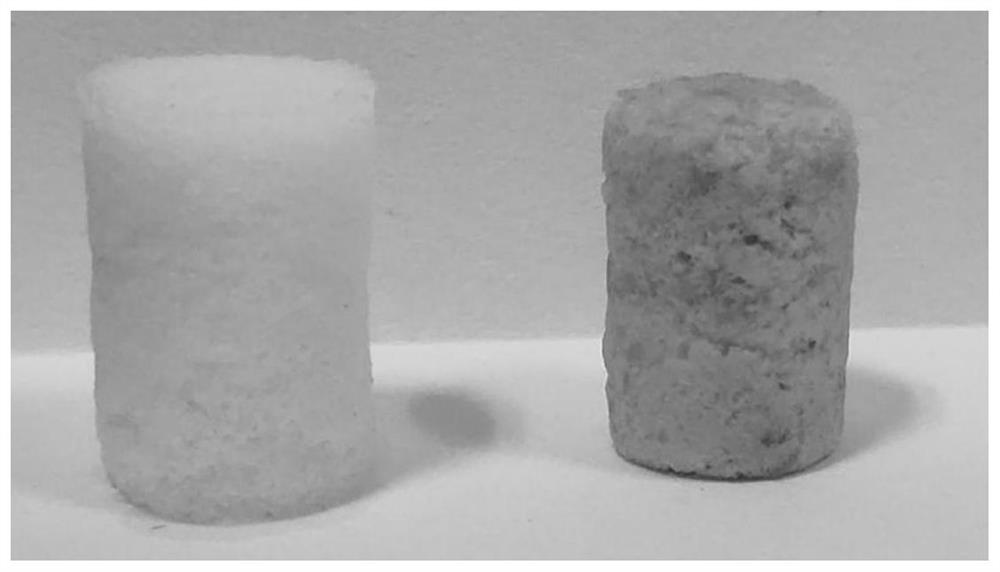

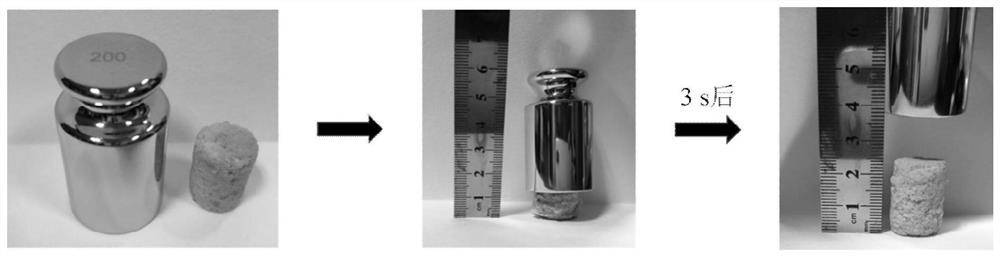

A technology for modifying cellulose and antibacterial materials, which is applied in the field of preparation of cellulose antibacterial materials based on natural active ingredients chlorogenic acid modification, can solve the problems of antibacterial agent loss, complicated process, easy to cause pollution, etc., and achieve good plasticity and elasticity, The preparation method is simple and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

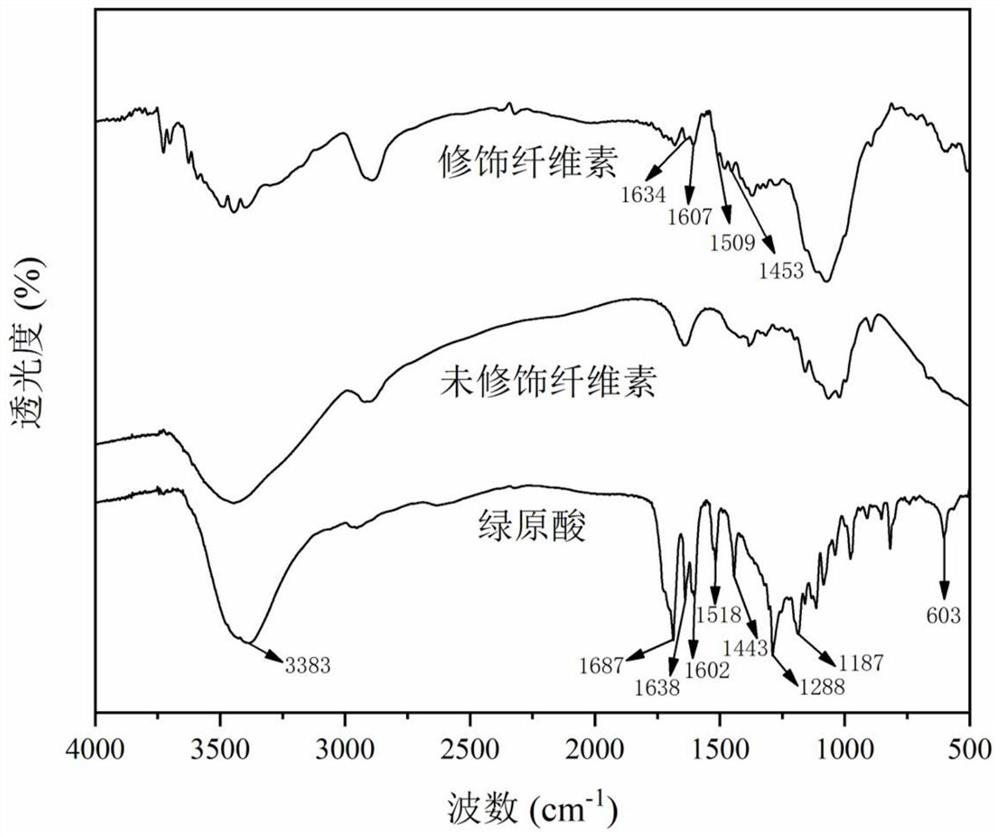

[0030] This embodiment is based on the preparation method of natural active ingredient chlorogenic acid modified cellulose antibacterial material, comprising the following steps:

[0031] Step 1, using sodium hydroxide, urea and a mixed aqueous solution to dissolve cellulose at -12°C to prepare a cellulose solution with a mass percentage of 3 wt %;

[0032] Step 2, adding anhydrous sodium sulfate with a mass ratio of 80% to the cellulose solution in step 2, mixing thoroughly and freezing at -20°C until completely solidified;

[0033] Step 3, soak the mixture in step 2 in 80°C hot water until the material floats on the water surface, then take out the deionized water and wash it;

[0034] Step 4, fully react the mixed solution of the material in step 3 with sodium hydroxide aqueous solution and epichlorohydrin at 60°C for 2 hours, wherein the concentration of sodium hydroxide aqueous solution is 3mol / L and epichlorohydrin and sodium hydroxide The volume ratio of the aqueous so...

Embodiment 2

[0047] A preparation method for modifying cellulose antibacterial material based on natural active ingredient chlorogenic acid, comprising the following steps:

[0048] Step 1, using sodium hydroxide, urea and a mixed aqueous solution to dissolve cellulose at -12°C to prepare a cellulose solution with a mass percentage of 3 wt %;

[0049] Step 2, adding anhydrous sodium sulfate with a mass ratio of 80% to the cellulose solution in step 2, mixing thoroughly and freezing at -20°C until completely solidified;

[0050] Step 3, soak the mixture in step 2 in 80°C hot water until the material floats on the water surface, then take out the deionized water and wash it;

[0051] Step 4, fully react the mixed solution of the material in step 3 with sodium hydroxide aqueous solution and epichlorohydrin at 60°C for 2 hours, wherein the concentration of sodium hydroxide aqueous solution is 3mol / L and epichlorohydrin and sodium hydroxide The volume ratio of the aqueous solution is 1:2, and ...

Embodiment 3

[0055] A preparation method for modifying cellulose antibacterial material based on natural active ingredient chlorogenic acid, comprising the following steps:

[0056] Step 1, using sodium hydroxide, urea and a mixed aqueous solution to dissolve cellulose at -12°C to prepare a cellulose solution with a mass percentage of 3 wt %;

[0057] Step 2, adding anhydrous sodium sulfate with a mass ratio of 80% to the cellulose solution in step 2, mixing thoroughly and freezing at -20°C until completely solidified;

[0058] Step 3, soak the mixture in step 2 in 80°C hot water until the material floats on the water surface, then take out the deionized water and wash it;

[0059] Step 4, wash the material in step 3 and then fully react with the mixed solution of sodium hydroxide aqueous solution and epichlorohydrin at 60 ° C for 2 hours, wherein the concentration of sodium hydroxide aqueous solution is 3mol / L and epichlorohydrin and epichlorohydrin The volume ratio of the sodium hydroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com