All-solid-state lithium ion battery composite positive electrode and preparation method thereof

A lithium-ion battery and composite positive electrode technology, which is applied in electrode manufacturing, battery electrodes, positive electrodes, etc., can solve the problems of inability to fully utilize the transmission of lithium ions, poor contact effect of inorganic solid electrolytes and positive electrode materials, etc., and achieve improved electrical conductivity. Low cost, convenient for large-scale industrial production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The positive electrode material lithium iron phosphate, the inorganic solid electrolyte LAGP, the conductive agent carbon black and the binder polyvinyl alcohol are ball milled for 4 hours according to the mass ratio of 90%:5%:2%:3% to prepare mixed powder.

[0039] Using supersonic plasma spraying equipment, under the conditions of 500 ° C and 2 MPa, using argon as a protective gas, spraying on the surface of the current collector aluminum foil to obtain a composite positive electrode material with a thickness of 50 μm.

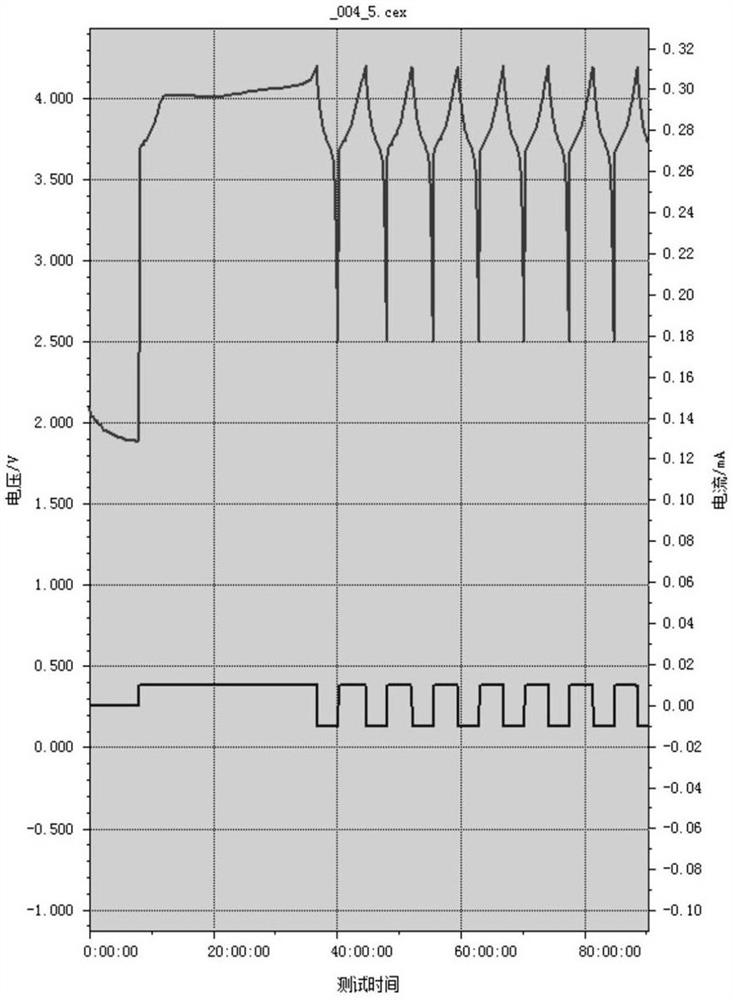

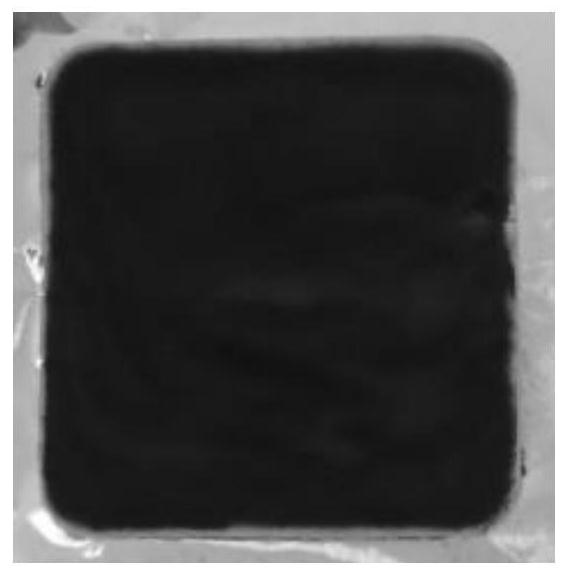

[0040] The photo of the composite cathode material prepared in Example 1 of the present invention is as follows figure 1 shown by figure 1 It can be seen that the method provided in Example 1 of the present invention can obtain a stable positive electrode sheet without powder dropping or falling off.

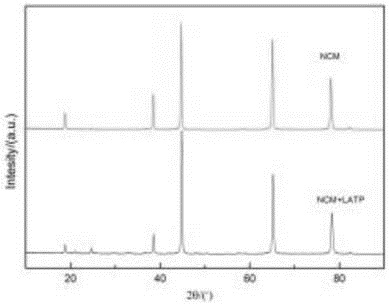

[0041] The XRD diffraction test was carried out on the composite positive electrode material prepared in Example 1 of the present invention. The test ...

Embodiment 2

[0044] The mixed powder is prepared by using the ternary material nickel cobalt lithium manganese oxide, inorganic solid electrolyte LATP, conductive agent carbon black and binder polytetrafluoroethylene according to the mass ratio of 90%: 4%: 4%: 2% by ball milling for 6 hours .

[0045] Using supersonic cold spraying equipment, under the conditions of 300 ° C and 1 MPa, nitrogen is used as a protective gas to spray on the surface of the current collector aluminum foil to obtain a composite positive electrode material with a thickness of 110 μm.

[0046] According to the method described in Example 1, the composite positive electrode material prepared in Example 2 of the present invention is detected, and the XRD diffraction results are as follows figure 2 As shown, the test results show that the positive pole piece adheres stably without falling powder or falling off; the crystal structure of the material is consistent with that of nickel-cobalt lithium manganese oxide, and...

Embodiment 3

[0048] The positive electrode material lithium cobaltate, inorganic solid electrolyte LLZO, conductive agent carbon black and carbon nanotubes (mass ratio 2:1) and binder polytetrafluoroethylene are ball milled according to the mass ratio of 92%: 3%: 2%: 3%. 8h prepared into a mixed powder.

[0049] Using supersonic cold spraying equipment, under the conditions of 350 ° C and 1.5 MPa, using argon as a protective gas, spraying on the surface of the current collector aluminum foil to obtain a composite positive electrode material with a thickness of 75 μm.

[0050] According to the method described in Example 1, the composite positive electrode material prepared in Example 3 of the present invention was tested, and the test results showed that the positive electrode sheet adhered stably without falling powder or falling off; the crystal structure of the material was consistent with that of lithium cobaltate and did not change. , The capacity of the active material of the positiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com