Glutamic acid fermentation method

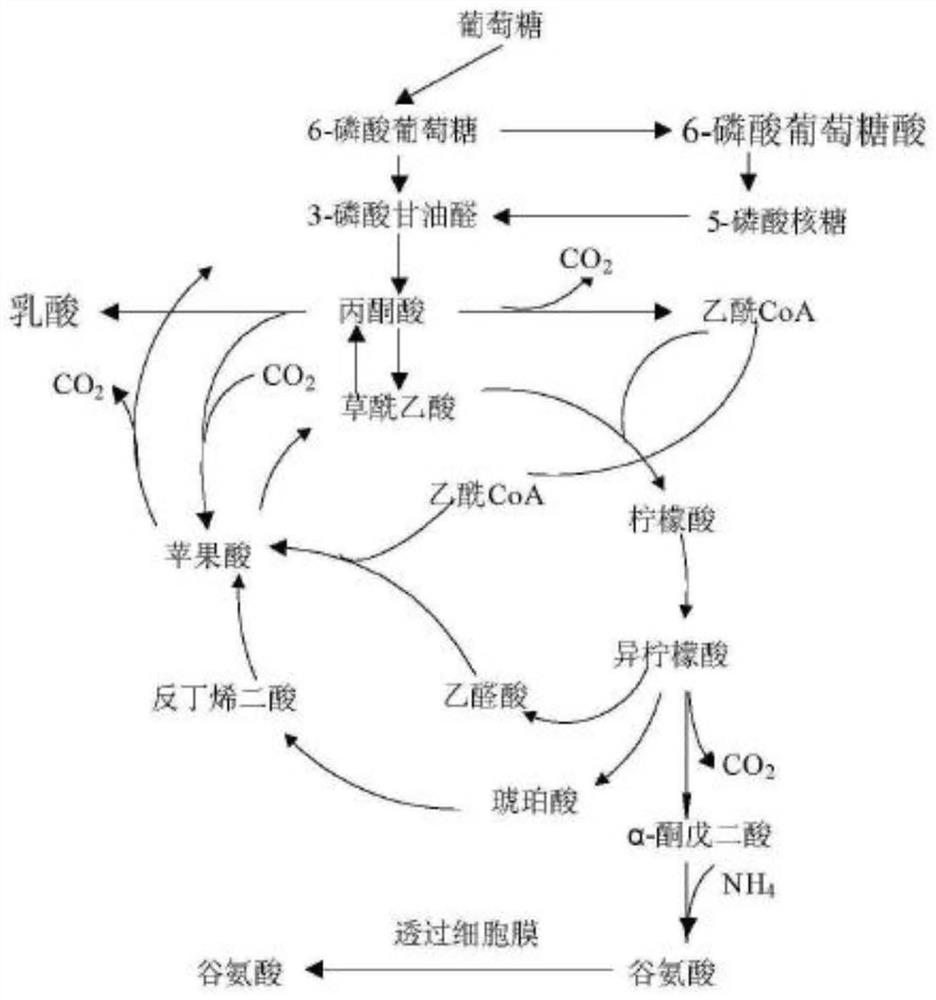

A fermentation method, glutamic acid technology, applied in the field of glutamic acid fermentation, can solve the problems of acid production rate and conversion rate decline, high free ammonia toxicity, weakened respiration, etc., to reduce osmotic pressure and improve bacterial growth Effects of environment, promotion of acidogenesis and glutamate efflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The present embodiment provides a method for improving glutamic acid fermentation acid production and conversion rate, comprising the steps of:

[0059] (1) Seed medium preparation: glucose 40g / L, corn steep liquor 30g / L, soybean meal hydrolyzate 15g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 1.2g / L, VB 1 100μg / L, biotin 200μg / L, FeSO 4 ·7H 2 O5mg / L, MnSO 4 ·H 2 O 5mg / L, succinic acid 1.5g / L, use sodium hydroxide to adjust the pH of the medium to 7.0-7.2, and sterilize at 121°C for 20min;

[0060] (2) Seed culture: the strain is thermosensitive Corynebacterium glutamicum for production. The strain stored in the glycerol tube was first spread on LB medium for activation and cultured overnight. Put them into a constant temperature reciprocating shaker in a 5L Erlenmeyer flask with a base, rotate at 120rpm, and temperature 32°C. Cultivate for 8-12h until the OD of the seed solution reaches 20 or above, then stop the cultivation.

[0061] (3) Fermentation medium preparati...

Embodiment 2

[0066] The present embodiment provides a method for improving glutamic acid fermentation acid production and conversion rate, comprising the steps of:

[0067] (1) Seed medium preparation: glucose 40g / L, corn steep liquor 30g / L, soybean meal hydrolyzate 15g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 1.2g / L, VB 1 100μg / L, biotin 200μg / L, FeSO 4 ·7H 2 O5mg / L, MnSO 4 ·H 2 O 5mg / L, succinic acid 1.5g / L, use sodium hydroxide to adjust the pH of the medium to 7.0-7.2, and sterilize at 121°C for 20min;

[0068] (2) Seed culture: the strain is thermosensitive Corynebacterium glutamicum for production. The strain stored in the glycerol tube was first spread on LB medium for activation and cultured overnight. Put them into a constant temperature reciprocating shaker in a 5L Erlenmeyer flask with a base, rotate at 120rpm, and temperature 32°C. Cultivate for 8-12h until the OD of the seed solution reaches 20 or above, then stop the cultivation.

[0069] (3) Fermentation medium preparati...

Embodiment 3

[0074] The present embodiment provides a method for improving glutamic acid fermentation acid production and conversion rate, comprising the steps of:

[0075] (1) Seed medium preparation: glucose 40g / L, corn steep liquor 30g / L, soybean meal hydrolyzate 15g / L, K 2 HPO 4 1g / L, MgSO 4 ·7H 2 O 1.2g / L, VB 1 100μg / L, biotin 200μg / L, FeSO 4 ·7H 2 O5mg / L, MnSO 4 ·H 2 O 5mg / L, succinic acid 1.5g / L, use sodium hydroxide to adjust the pH of the medium to 7.0-7.2, and sterilize at 121°C for 20min;

[0076] (2) Seed culture: the strain is thermosensitive Corynebacterium glutamicum for production. The strain stored in the glycerol tube was first spread on LB medium for activation and cultured overnight. Put them into a constant temperature reciprocating shaker in a 5L Erlenmeyer flask with a base, rotate at 120rpm, and temperature 32°C. Cultivate for 8-12h until the OD of the seed solution reaches 20 or above, then stop the cultivation.

[0077] (3) Fermentation medium preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com