Miniature thermoelectric device and preparation method thereof

A thermoelectric device, thermoelectric technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts, etc., can solve the problems of low automation, stability and refrigeration performance, achieve good dimensional consistency, avoid wear and tear Pollution, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

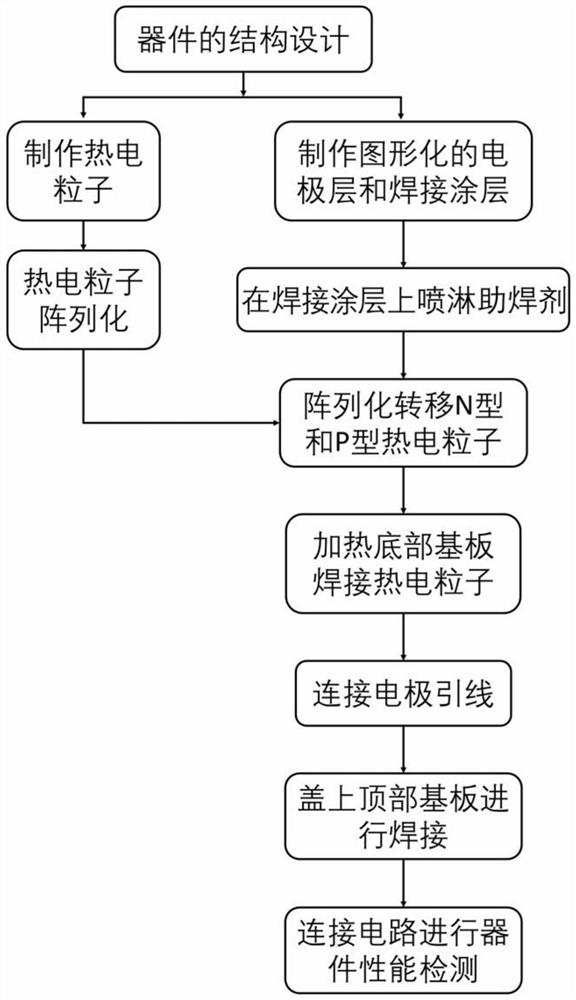

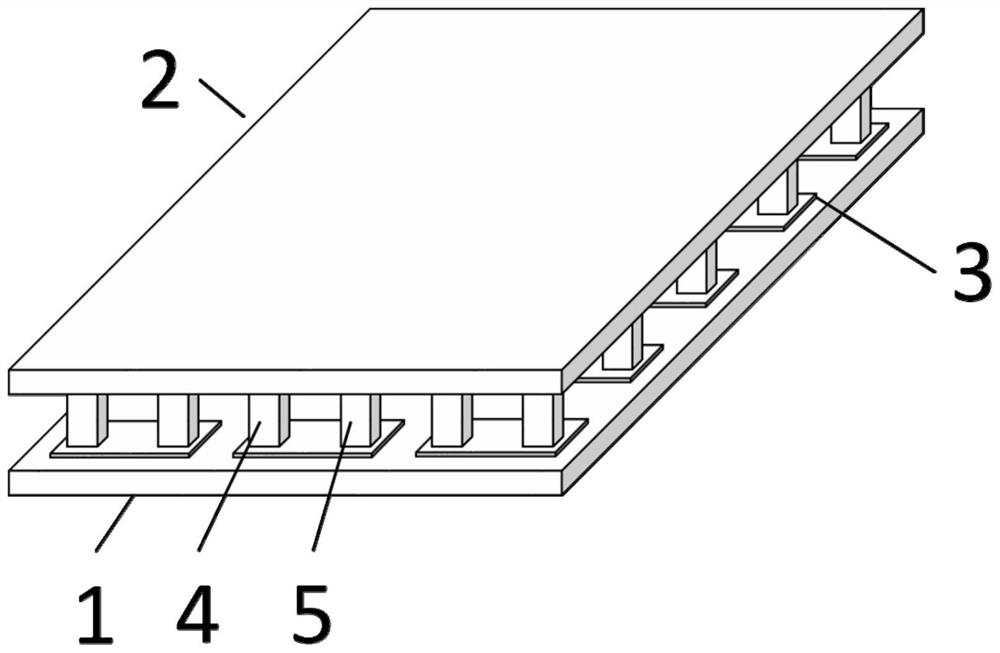

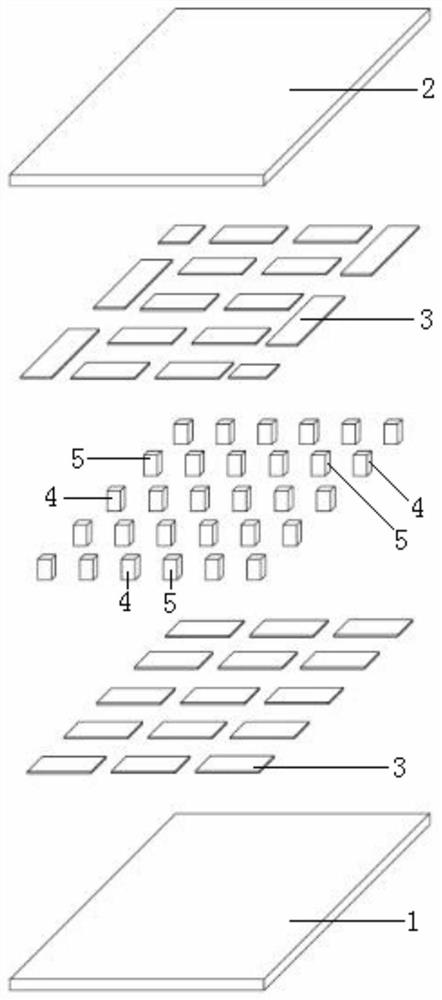

[0064]Such asFigure 1-Figure 4As shown, the structure design drawing of the device manufactured in this embodiment, and the manufacturing method refer to the foregoing implementation process. For the Transistor Out-line (TO) package Distributed Feedback Laser (DFB) laser used in the optical fiber communication network, the device structure and performance were simulated using finite element simulation software, and a micro thermoelectric device was designed. The bottom substrate of the micro thermoelectric device is a Plane, solder paste is used as the interface layer, and it is attached to the TO package base. The laser chip is also attached to the upper surface of the micro thermoelectric device through solder paste. The electrode wires of the micro thermoelectric device are connected to the electrode pins on the TO package base through solder, etc., which can realize energization and cooling. A thermistor is attached to the side of the laser or the cold end of the TEC for real-ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com