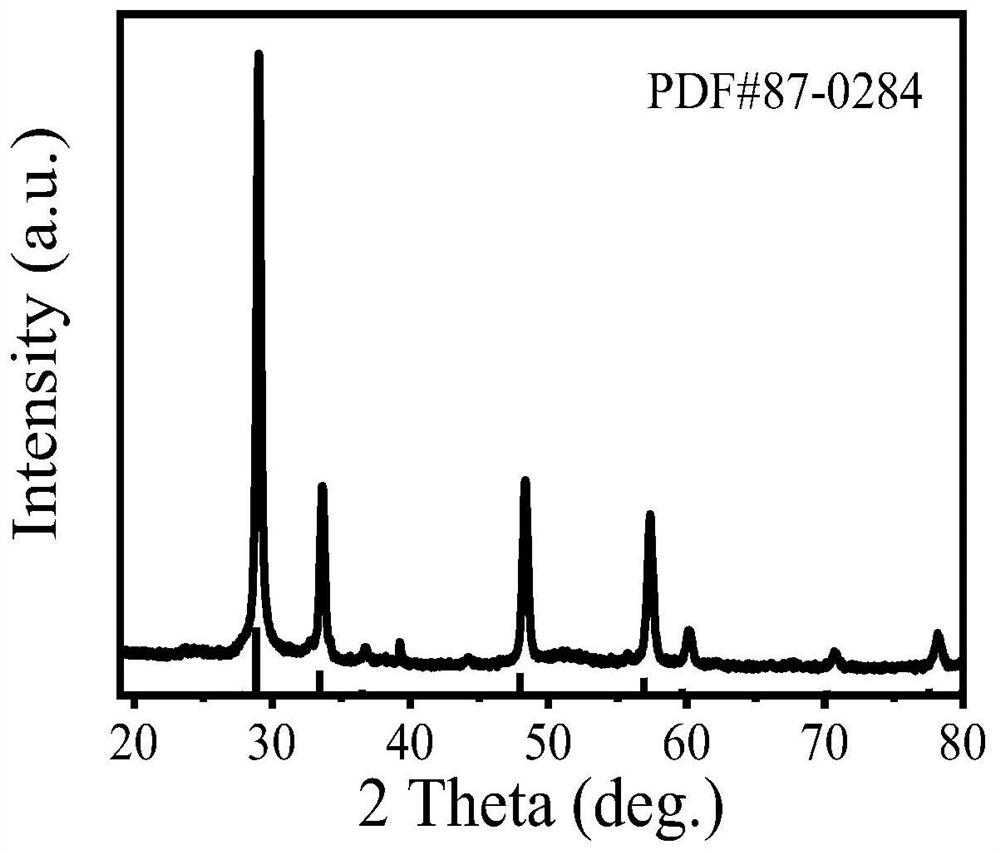

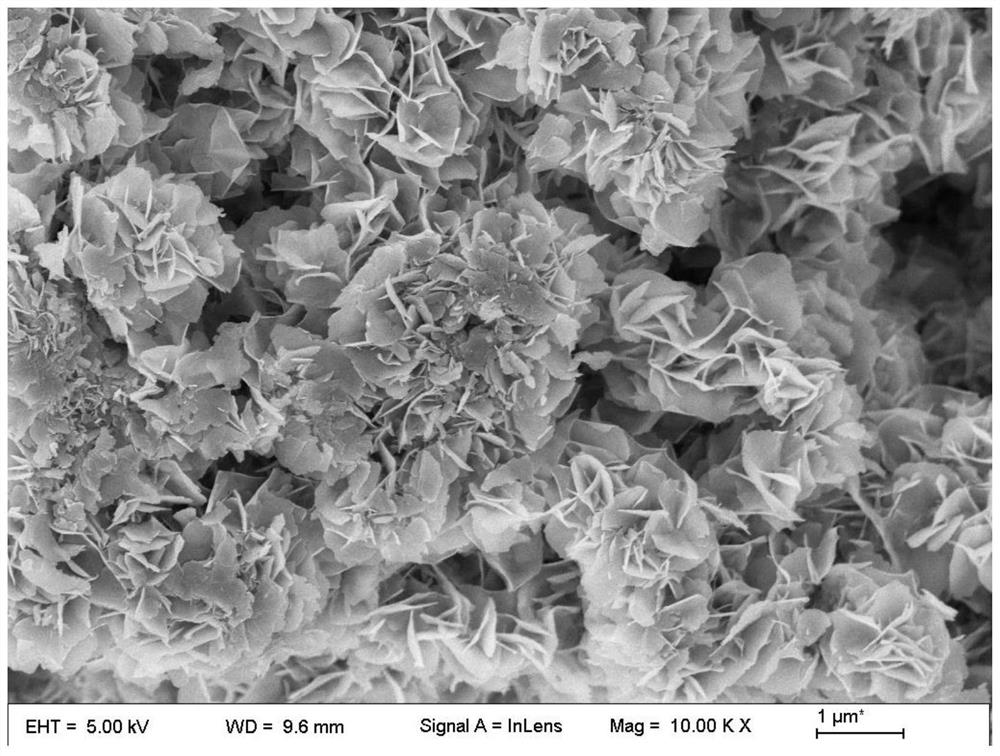

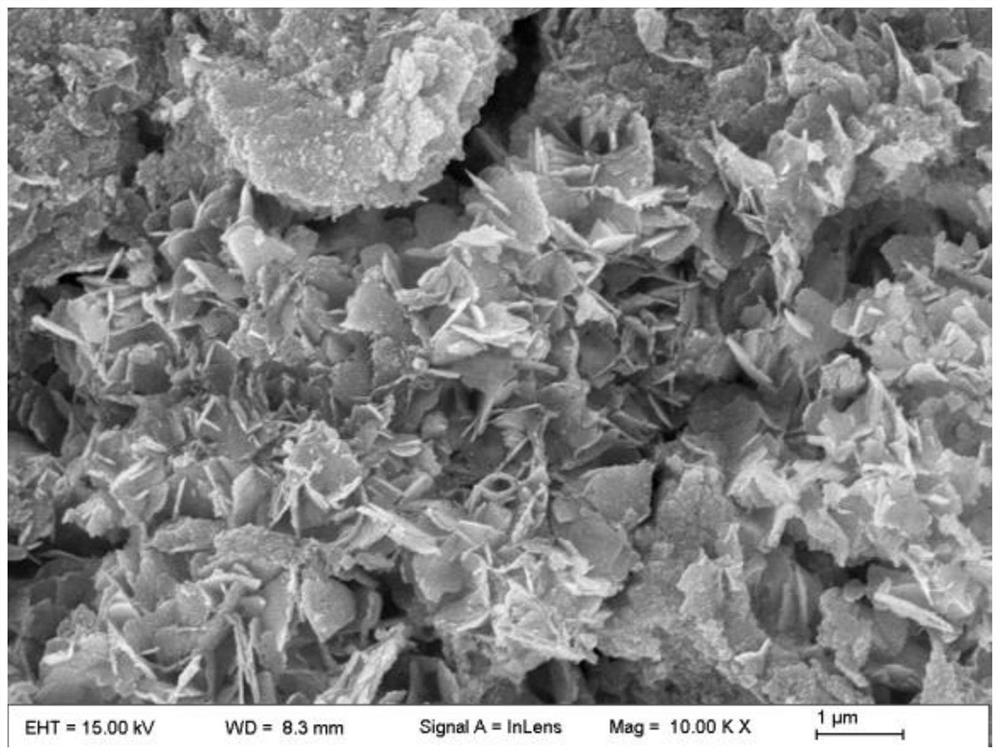

Preparation method of flower-cluster-shaped bismuth stannate nano-powder

A nano-powder, bismuth stannate technology, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of difficult mass production, high energy consumption of the preparation process, long production cycle, etc., and achieve crystallinity Excellent, cheap and easy to obtain raw materials, short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Prepare 50ml of 0.025mol / L bismuth sulfate dilute acid solution, the solvent is dilute sulfuric acid, which is recorded as A solution;

[0036] (2) Prepare 50ml 0.025mol / L potassium stannate aqueous solution, denoted as B solution;

[0037] (3) Put solution B in a separatory funnel and add it dropwise to solution A at a constant speed of 2ml / s under magnetic stirring at 600r / min to form a translucent emulsion;

[0038] (4) Add 2g of citric acid gelling agent and 0.2g of polyethylene glycol-2000 dispersant to the translucent emulsion respectively. After fully mixing, add 30% NaOH solution dropwise to the pH of the mixed solution to 8. Continue to stir at room temperature for 30 minutes; age for 3 hours, remove the supernatant, wash with deionized water and alcohol, centrifuge, and separate, repeat 3 times, and then put it in a blast-type drying box, and dry at 80°C for 12 hours. A white drying powder is obtained, that is, a bismuth stannate nano-powder precursor;

...

Embodiment 2

[0041] (1) Prepare 50ml 0.05mol / L bismuth nitrate dilute acid solution, the solvent is dilute nitric acid, which is recorded as A solution;

[0042] (2) Prepare 50ml of 0.05mol / L sodium stannate aqueous solution, denoted as B solution;

[0043] (3) Put solution B in a separatory funnel and add it dropwise to solution A at a constant speed of 2.5ml / s under magnetic stirring at 600r / min to form a translucent emulsion;

[0044] (4) Add 2g of citric acid gelling agent and 0.3g of polyethylene glycol-2000 dispersant to the translucent emulsion respectively. After fully mixing, add NaOH solution dropwise until the pH of the mixed solution reaches 10, and continue to stir at room temperature 30min; aged for 4h, removed the supernatant, washed with deionized water and alcohol, centrifuged and separated, repeated 4 times, and then put it into a blast-type drying box and dried at 80°C for 12h to obtain a white drying powder , the precursor of bismuth stannate nano-powder;

[0045] (5)...

Embodiment 3

[0047] (1) Prepare 50ml of 0.04mol / L bismuth chloride dilute acid solution, the solvent is dilute hydrochloric acid, denoted as A solution;

[0048] (2) Prepare 50ml of 0.04mol / L tin tetrachloride aqueous solution, denoted as B solution;

[0049] (3) Put solution B in a separatory funnel and add it dropwise to solution A at a constant speed of 2.5ml / s under 600r / min magnetic stirring to form a translucent emulsion;

[0050] (4) Add 2.5g of citric acid gelling agent and 0.2g of polyethylene glycol-2000 dispersant to the translucent emulsion. After mixing well, add NaOH solution dropwise until the pH of the mixed solution reaches 12, and continue to store at room temperature. Stir at low temperature for 30 minutes; age for 6 hours, remove the supernatant, wash with deionized water and alcohol, centrifuge, and separate, repeat 5 times, then put it in a blast drying oven, dry at 80°C for 12 hours, and obtain a white drying Powder, namely bismuth stannate nanopowder precursor;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com