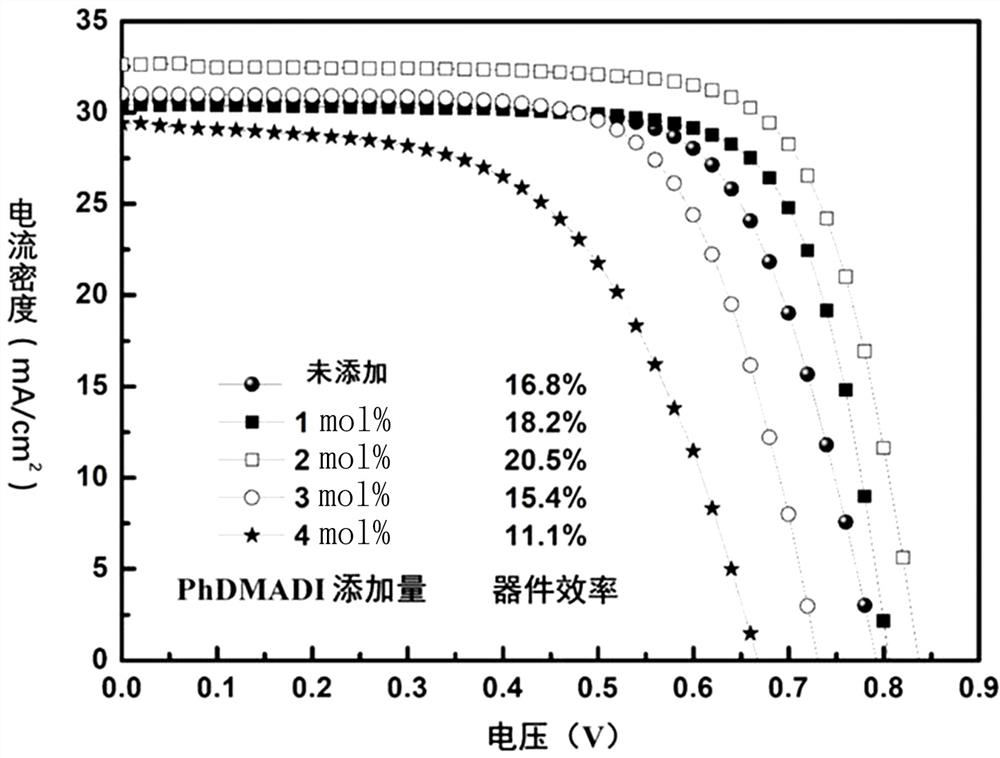

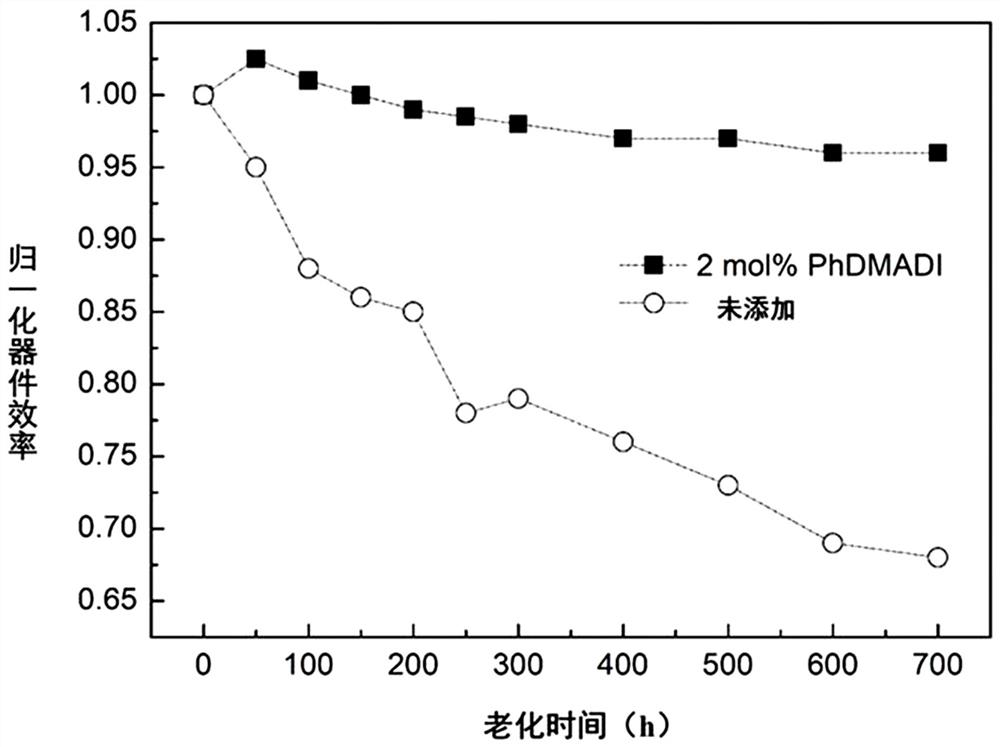

Preparation method of tin-lead hybrid perovskite battery passivated by p-phenyldimethylamine iodide

A technology of phenyldimethylamine iodide and methylamine iodide is applied in the field of preparation of tin-lead mixed perovskite solar cells, which can solve the problems of high formation energy and reduce the trap density of perovskite film, and achieves Improved crystallinity and morphology, reduced defect density, and improved performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preparation method of the present embodiment is as follows:

[0026] 1)FA 0.7 MA 0.3 Pb 0.5 Sn 0.5 I 3 Preparation of Perovskite Precursor Solution

[0027] First, 168.5 mg of formamide iodide (FAI), 66.8 mg of methylamine iodide (MAI), 322.7 mg of PbI 2 , 260.8mg of SnI 2 , 11.0mg SnF 2 750 μL of dimethylformamide (DMF) and 250 μL of dimethyl sulfoxide (DMSO) were added, followed by adding 0-4 mol% PhDMADI to the mixed solution. Subsequently, the precursor solution was stirred at 60 °C for 2 h and then filtered with a 0.20 μm polytetrafluoroethylene (PTFE) filter to finally obtain 1.4 M FA 0.7 MA 0.3 Pb 0.5 Sn 0.5 I 3 Perovskite precursor solution.

[0028] 2) ITO glass cleaning

[0029] First, use glass detergent to clean the ITO glass substrate (15×15mm 2 ), rinsed repeatedly with deionized water, then ultrasonically treated with acetone and isopropanol for 15 min in turn, dried with nitrogen, and finally treated in a UV-ozone cleaning machine for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com