Graphene oxide nano filtration membrane prepared by blending and reducing layered MoS2 nano sheets and preparation method thereof

A technology of nanosheets and graphene, which is applied in the field of layered MoS2 nanosheet blended and reduced graphene oxide nanofiltration membranes and its preparation, can solve the problems of low water flux, achieve simple preparation process, and improve water flux And selectivity, stable and reliable effect of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A layered MoS 2 The preparation method of the graphene oxide dye removal nanofiltration membrane comprising the steps of:

[0043] Take 0.012g of GO powder and disperse it in 60ml of deionized water, sonicate for 2h to obtain a concentration of 0.2mgmL -1 GO dispersion, and then 30mL of GO dispersion was placed in a 50mL autoclave, heated and reacted at 120°C for 9h, and the rGO dispersion was obtained after natural cooling for 2h, which was placed for use.

[0044] Weigh 0.1g commercial MoS 2 Powder and 5mg NaOH powder in 20mL NMP, after stirring, sonicate for 2h, then let it stand for 24h. Take the supernatant and centrifuge at 2000rpm for 30min, discard the sediment to remove the unstripped MoS 2 or thick slices. Take the supernatant again and centrifuge at 9000 rpm for 45 min, discard the supernatant and add fresh NMP to repeat centrifugation to remove free sodium hydroxide. The MoS obtained after repeated centrifugation 2 The precipitate was dried at low temp...

Embodiment 2

[0047] A layered MoS 2 The preparation method of the graphene oxide dye removal nanofiltration membrane comprising the steps of:

[0048] Disperse 0.012g of GO powder in 60ml of deionized water and sonicate for 4h to obtain a concentration of 0.2mgmL -1 GO dispersion, and then 30mL of GO dispersion was placed in a 50mL autoclave, heated and reacted at 120°C for 9h, and the rGO dispersion was obtained after natural cooling for 1h, which was placed for use.

[0049] Weigh 0.1g commercial MoS 2 powder and 5mg NaOH powder were added to 20mL NMP-H 2 O, ultrasonic 4h after stirring, and then stand for 30h. Take the supernatant and centrifuge at 2000rpm for 60min, discard the sediment to remove the unstripped MoS 2 or thick slices. Take the supernatant again and centrifuge at 9000rpm for 60min, discard the supernatant and add fresh NMP-H 2 O Repeated centrifugation to remove free NaOH. The MoS obtained after repeated centrifugation 2 Dry the precipitate at low temperature, ta...

Embodiment 3

[0052] The difference from Example 1 is that the layered molybdenum disulfide nanosheets are added in an amount of 10 ml, that is, the loading amount of molybdenum disulfide is 33.33% of the reduced graphene oxide.

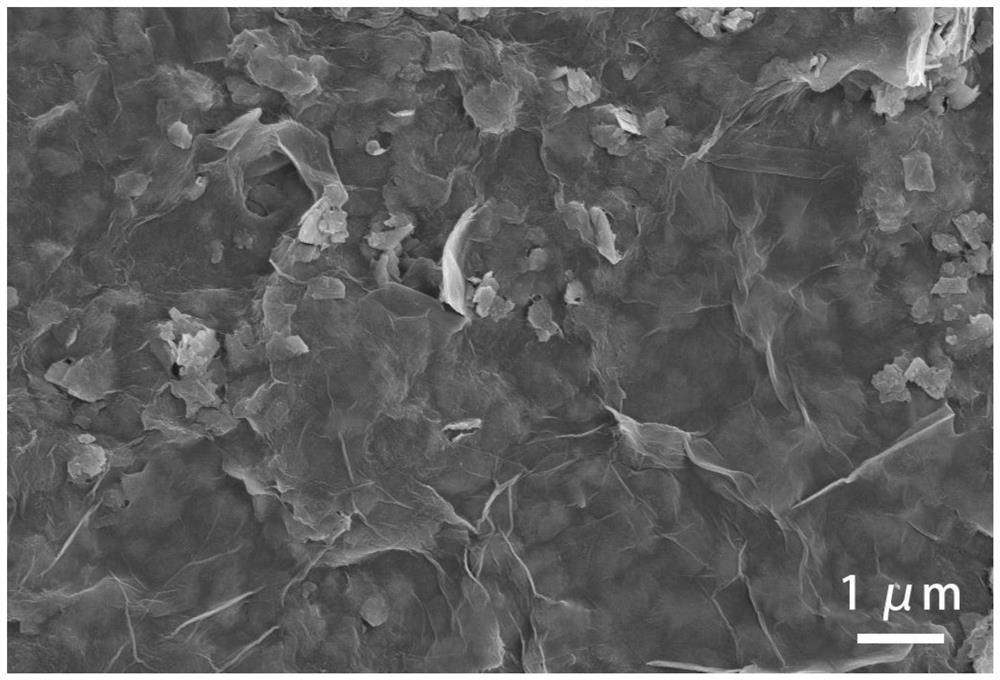

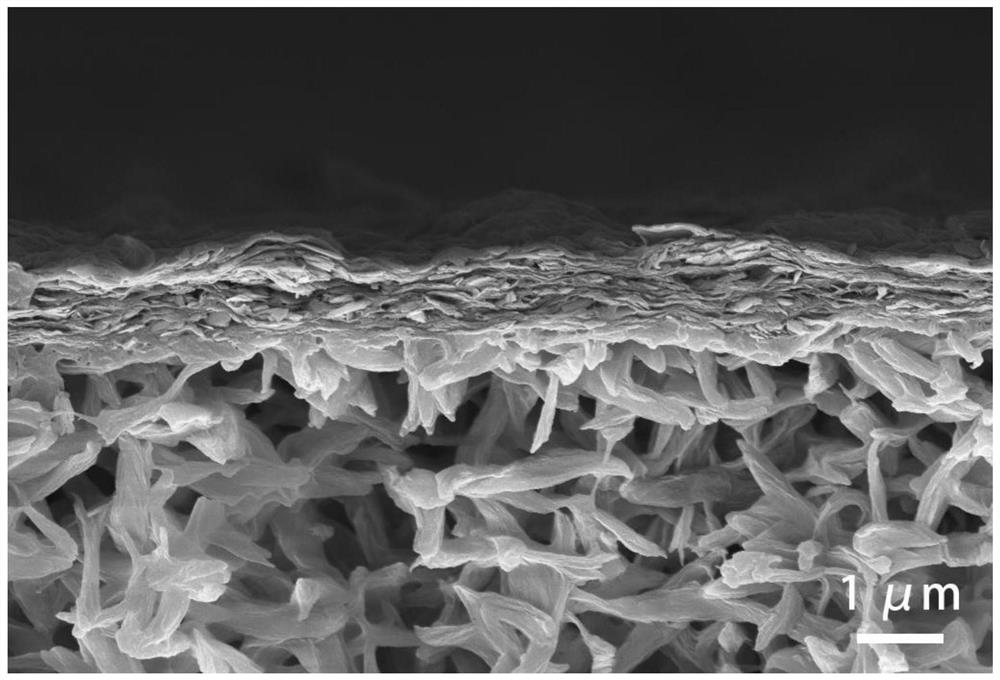

[0053] figure 1 It is the surface scanning electron microscope picture of embodiment 3; figure 2 It is a cross-sectional scanning electron microscope picture of Example 3. From figure 1 It can be seen that the MoS2 nanosheets are evenly attached to the rGO thin layer, and the layers are stacked. The insertion of the MoS2 nanosheets causes pinholes or defects on the film surface, that is, no homogeneous smooth film layer is formed, providing more water molecules. transmission channel. From its section figure 2 It can be seen that rGO and MoS2 are stacked layer by layer, showing a slightly rough and loose layered structure, which is due to the voids formed by some aggregated MoS2 nanosheets, and the higher the MoS2 content in the hybrid film, the higher the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com