Multi-element co-doped visible-light-induced photocatalyst

A co-doping, visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult separation from treated water, restricting practical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

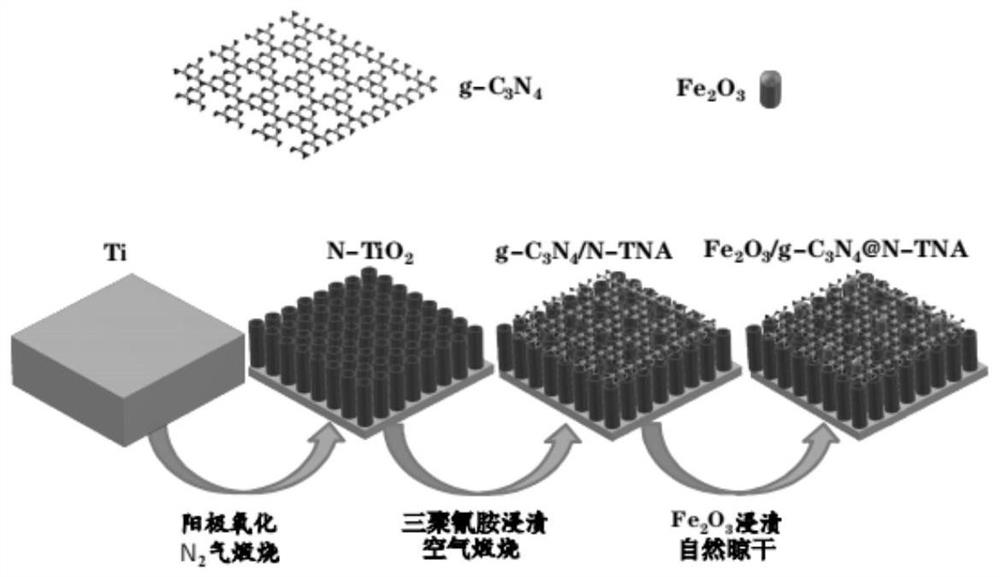

[0022] The preparation method of the visible light catalyst with the magnetic separation function is as follows:

[0023] 1. Polish the titanium sheet (25mm×40mm) with 180#, 600#, and 1000# sandpaper in turn until it shows a metallic luster, put the polished titanium sheet into absolute ethanol and deionized water for 10 minutes, and then let it dry naturally . The configuration contains a mass fraction of 0.4% NH 4 F and a volume fraction of 1% H 2 The ethylene glycol mixture of O is used as the electrolyte, the titanium sheet is used as the anode, and the steel plate is used as the cathode. The electrolytic cell experiment is carried out under the condition of a constant voltage of 30v for 1h, accompanied by magnetic stirring. After the reaction, the titanium sheet is taken out and used a large amount of Rinse with deionized water, air-dry naturally, and place in a muffle furnace for high-temperature simmering treatment. The heating rate was 5°C / min. When the maximum temp...

Embodiment 1

[0027] Example 1 TNA Visible Light Catalytic Degradation of Bisphenol A Solution

[0028] Reaction target solution volume: 100mL

[0029] Reaction target solution: bisphenol A concentration is 4mg / L

[0030] pH 7

[0031] Catalyst dosage is 10cm 2

[0032] Illuminate for 120min under simulated visible light (CEL-HXUV300, Beijing Zhongjiao Jinyuan, 200-800nm, 300W)

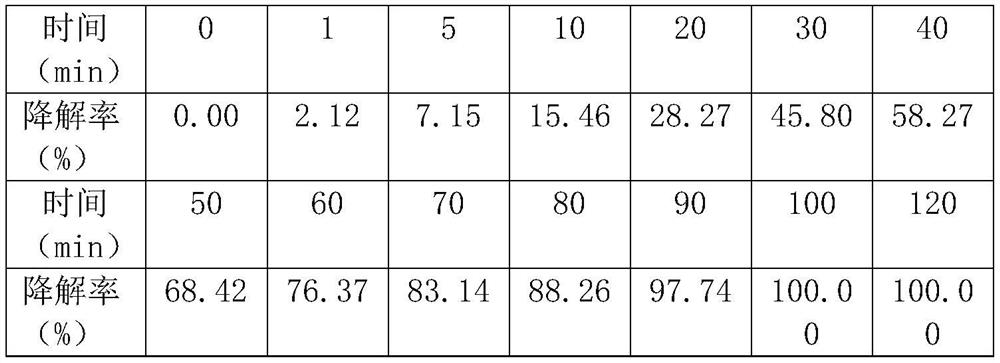

[0033] The removal rate of bisphenol A solution before and after treatment is shown in Table 1.

[0034] Table 1 Example 1 Visible light catalytic degradation bisphenol A solution removal rate results

[0035]

Embodiment 2

[0036] Example 2 N-TNA visible light catalytic degradation of bisphenol A solution

[0037] Reaction target solution volume: 100mL

[0038] Reaction target solution: bisphenol A concentration is 4mg / L

[0039] pH 7

[0040] Catalyst dosage is 10cm 2

[0041] Illuminate for 120min under simulated sunlight (CEL-HXUV300, Beijing Zhongjiao Jinyuan, 200-800nm, 300W)

[0042] The removal rate of bisphenol A solution before and after treatment is shown in Table 2.

[0043] Table 2 Example 2 Visible light catalytic degradation bisphenol A solution removal rate results

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com