Household garbage incineration fly ash reduction recycling treatment method

A technology of domestic waste incineration and treatment method, applied in the field of domestic waste incineration fly ash reduction and recycling, can solve problems such as affecting the operation efficiency of cement kilns, reducing cement quality, flue gas pollution, etc., to achieve harmless treatment, The effect of reducing emissions and reducing environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

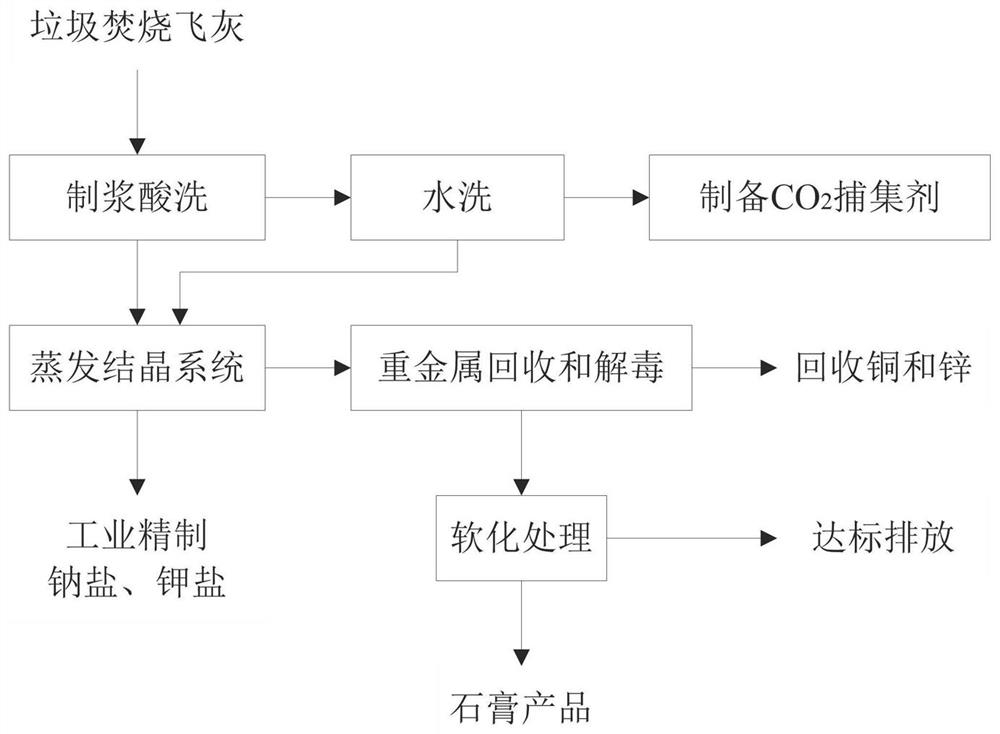

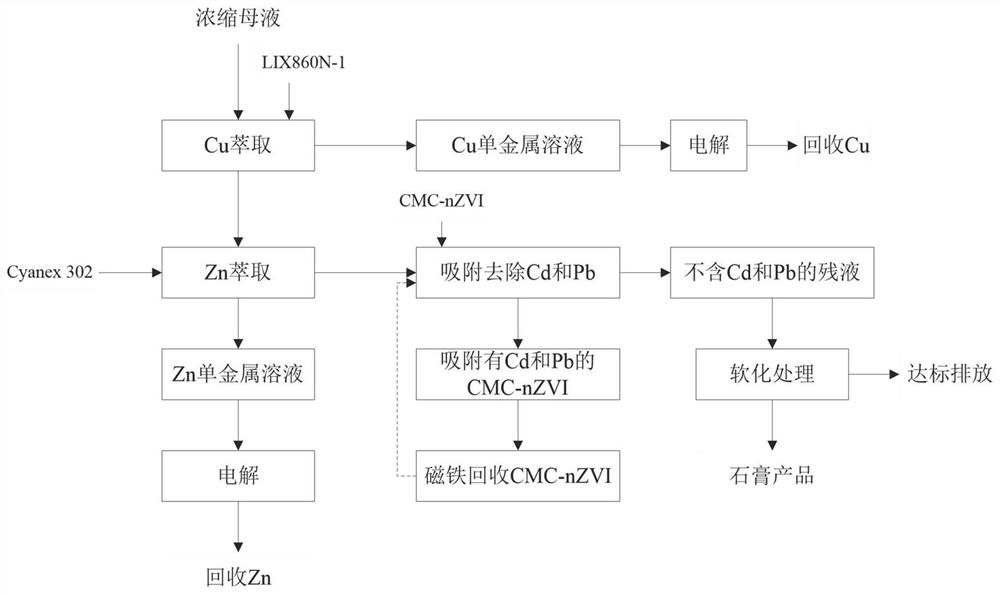

[0033]Such asfigure 1 As shown, a recycling method for reducing the amount of fly ash from domestic waste incineration, the specific steps are as follows:

[0034]Step 1. Add the fly ash, hydrochloric acid and hydrogen peroxide solution to the pickling tank and stir and mix to produce pickling slurry; considering the leaching efficiency and acid consumption, adjust the pH of the solution to 2.5; the liquid-solid of the pickling slurry The ratio is 2:1. The duration of the stirring reaction is 45 minutes, and most of the chlorine and heavy metal ions in the fly ash are leached out; the mass fraction of hydrochloric acid is 5%, and the mass fraction of hydrogen peroxide in the hydrogen peroxide solution is 35%; Hydrogen oxide optimizes the acid leaching process; adding the oxidizing agent hydrogen peroxide during the stirring process of the pickling slurry can maintain the oxidation conditions during the entire leaching period, keeping the oxidation-reduction potential constant at greate...

Embodiment 2

[0050]The difference from the first embodiment is that the use of citric acid to replace the hydrochloric acid + hydrogen peroxide; the solution pH is adjusted to 3: 1. The metal chelate is formed by forming a metal chelate with a metal cation in a solution to form a metal ion, thereby increasing the leaching reaction.

[0051]Through the method described in this example, the initial conditions are: chlorine (CL) content is 16.32%, copper (Cu) content is 0.985 mg / g, and zinc (Zn) content is 5.783 mg / g, cadmium (CD) content is 0.186 mg / g, lead (PB) content is a flying ash of 2.887 mg / g for resource treatment test, and the decochlorination ratio of fly ash reaches 96% to 98%, and the leaching rate of copper (Cu) reaches 98% ± 2%. The leaching rate of zinc (Zn) reached 80% ± 1%, cadmium (CD) leaching rate reached 97% ± 2%, lead (Pb) leaching rate reached 84% ± 1%; through step six in SRE + electrolysis The total recovery rate of Cu reaches 90%, and the total recovery rate of Zn re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com