Ultra-wide spectrum perovskite white light material as well as preparation and application thereof

A perovskite and white light technology, which is applied in luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., to achieve excellent wide-spectrum white light emission characteristics, low pollution, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Ultra Broad Spectrum (2-AA) 2 PB 4 The synthesis method of white LED material is as follows: 1) Dissolve 0.1g of 2-aminoanthracene (2-AA) in 150mL of ethanol, add 5mL of hydroiodic acid (HI) solution (55-58wt%), and remove by rotary evaporation at 60°C for 30min After most of the solvent, vacuum-dry at 60°C to obtain the hydroiodide (2-AAI) of 2-aminoanthracene; 2) combine 2-AAI with lead iodide (PbI 2 ) was dissolved in N,N-dimethylformamide (DMF) under heating and stirring at 150°C at a molar ratio of 2:1, and 2-AAI and PbI were controlled 2 The total concentration of the mixed solution is 0.88g / mL; 3) Spin-coat the DMF solution in step 2) on a glass slide preheated at 150°C at a spin-coating speed of 3000rpm, heat to 140°C in air and anneal to remove residual solvent , a layer of (2-AA) can be formed on the glass surface 2 PB 4 perovskite film.

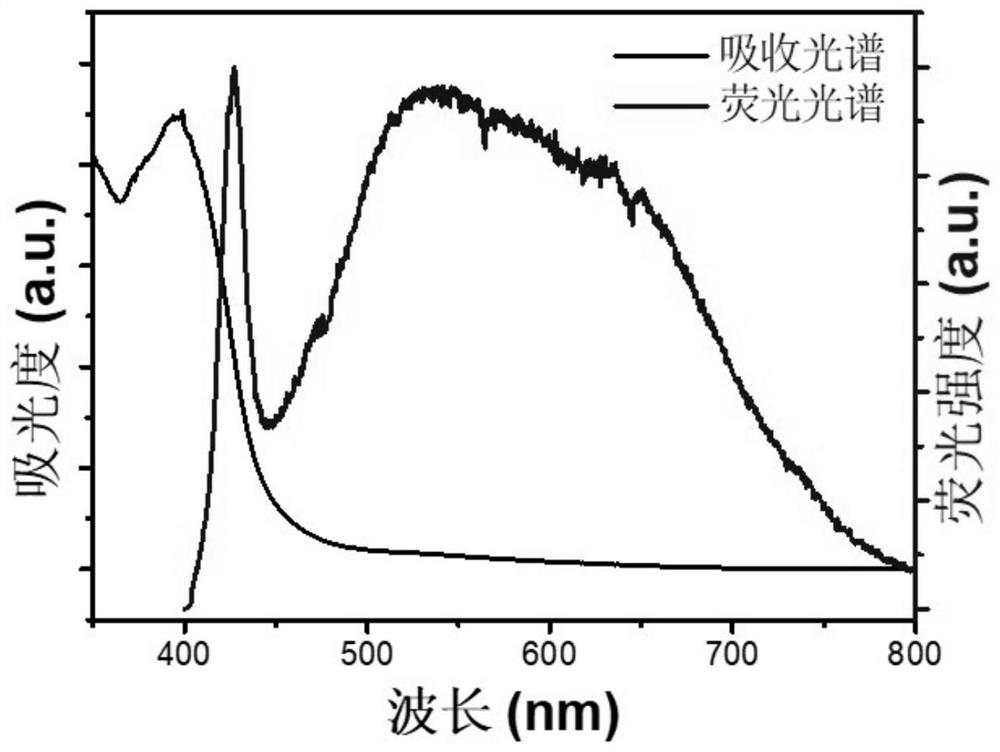

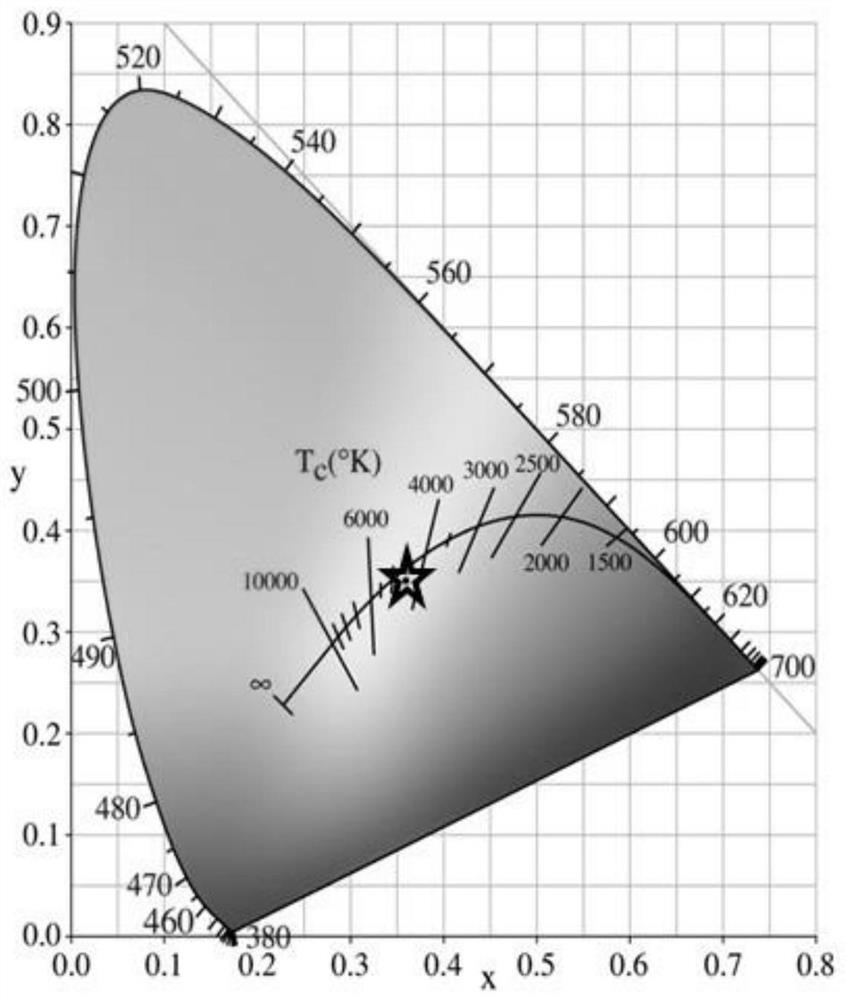

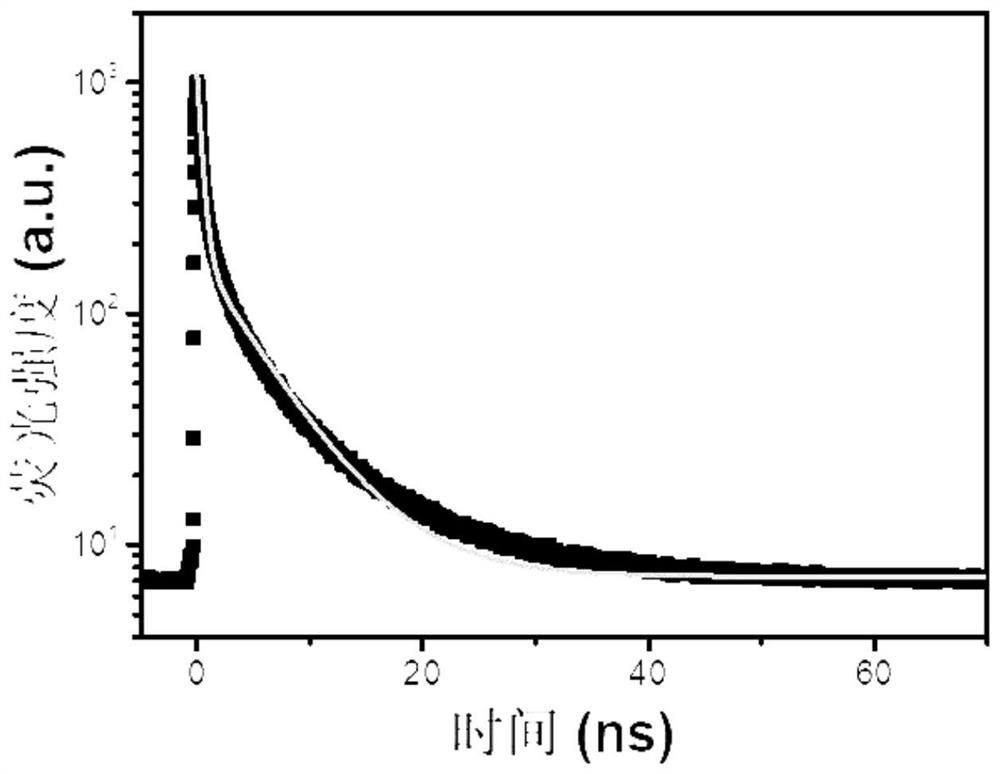

[0033] figure 1 is ultra-broad spectrum (2-AA) 2 PB 4The UV-Vis absorption spectrum (black) and fluorescence emiss...

Embodiment 2

[0039] In order to check the quality of 2-AA to Ultra Broad Spectrum (2-AA) 2 PB 4 The influence of white LED materials, except the mass of 2-AA is 0.02, 0.05, 0.2 and 0.4g, other conditions are as follows: HI volume (5mL), 2-AAI and PbI 2 Molar ratio (2:1), 2-AAI and PbI 2 Heating temperature of mixed solution (140°C), 2-AAI and PbI 2 The total concentration of the DMF mixed solution (0.88g / mL), glass preheating temperature (140°C), spin coating speed (3000rpm), annealing temperature (100°C) and other conditions are all the same as in Example 1. The results show that when the 2-AA quality is 0.02 and 0.05g, because the concentration of 2-AA in ethanol is too low, although it can react completely, the production efficiency is too low, which is about 1 / 2 of that when the amount of 2-AA is 0.1g. 5 and 1 / 2, and cause waste of solvent. When the mass of 2-AA is 0.2 and 0.4g, it is difficult to completely dissolve the excess 2-AA, resulting in incomplete subsequent acid-base neu...

Embodiment 3

[0041] To examine the volume of HI versus ultrabroad spectrum (2-AA) 2 PB 4 The influence of white LED materials, except the volume of HI is 0.2, 1.0, 20 and 50mL, other conditions are as follows: 2-AA mass (0.1g), 2-AAI and PbI 2 Molar ratio (2:1), 2-AAI and PbI 2 Heating temperature of mixed solution (140°C), 2-AAI and PbI 2 The total concentration of the DMF mixed solution (0.88g / mL), glass preheating temperature (140°C), spin coating speed (3000rpm), annealing temperature (100°C) and other conditions are all the same as in Example 1. The results show that when the volume of HI is 0.2 and 1.0mL, the 2-AA reaction is not complete due to the insufficient amount of HI, resulting in a large amount of unreacted 2-AA remaining in the synthesized 2-AAI, and the purity of the product at this time is analyzed from the spectrum Much lower than the purity when HI dosage is 5mL. When the volume of HI is 20 and 50mL, the excess of HI leads to waste of raw materials, and a large amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com