A kind of reusable Raman enhanced substrate and its preparation method and application

A substrate and Raman technology, applied in Raman scattering, nanotechnology for sensing, nanotechnology for materials and surface science, etc., can solve the problem that uniformity affects the quality of SERS substrate, the uniformity of nanoparticles, The problem of high cost of physical methods can achieve the effect of improving SERS performance, improving optical absorption performance, and improving SERS performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

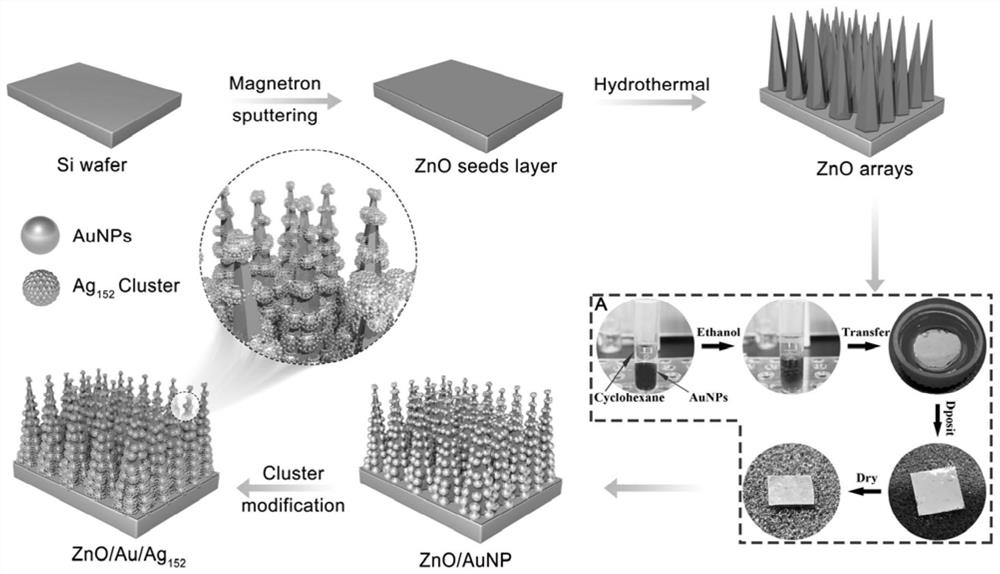

[0050] A protocol for the preparation of a novel reusable Raman-enhanced substrate.

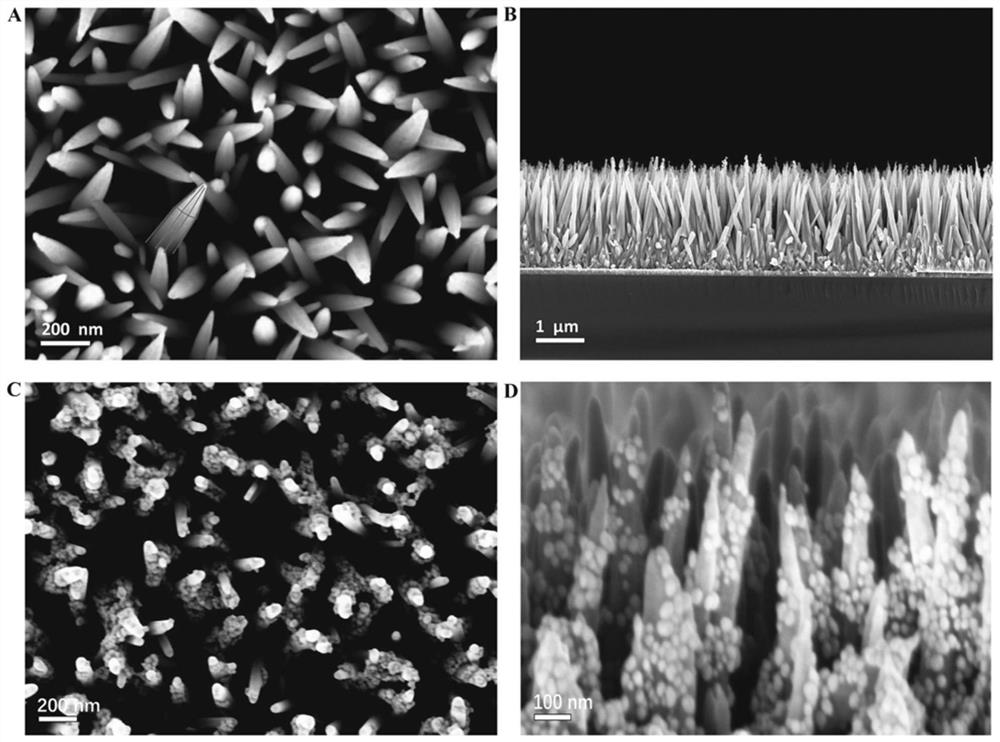

[0051] (1) ZnO seed crystal preparation: magnetron sputtering method, 1) with P(111) type single crystal silicon wafer as the substrate, P(111) type single crystal silicon wafer (1×1cm 2 ) Ultrasonic cleaning with acetone for 15 minutes before sputtering, rinse with deionized water, ultrasonic cleaning with absolute ethanol for 15 minutes, rinse with deionized water, and ultrasonic cleaning with deionized water for 15 minutes to ensure that the surface ions are completely removed. After cleaning, use nitrogen flow Blow dry and store in a vacuum. 2) Sputtering A ZnO ceramic target with a purity higher than 99.99% is used, and pre-sputtering is performed on it for 10 minutes to remove surface impurities. 3) Vacuum degree 3×10 -5 Torr, the vacuum atmosphere is Ar and O with a purity better than 99% 2 Gas mixture, the flow rate is 10:10 (sccm), the sputtering pressure is about 1Pa, the sputter...

Embodiment 2

[0058] The SERS performance of the new three-dimensional substrate was evaluated by using crystal violet and rhodamine B molecules.

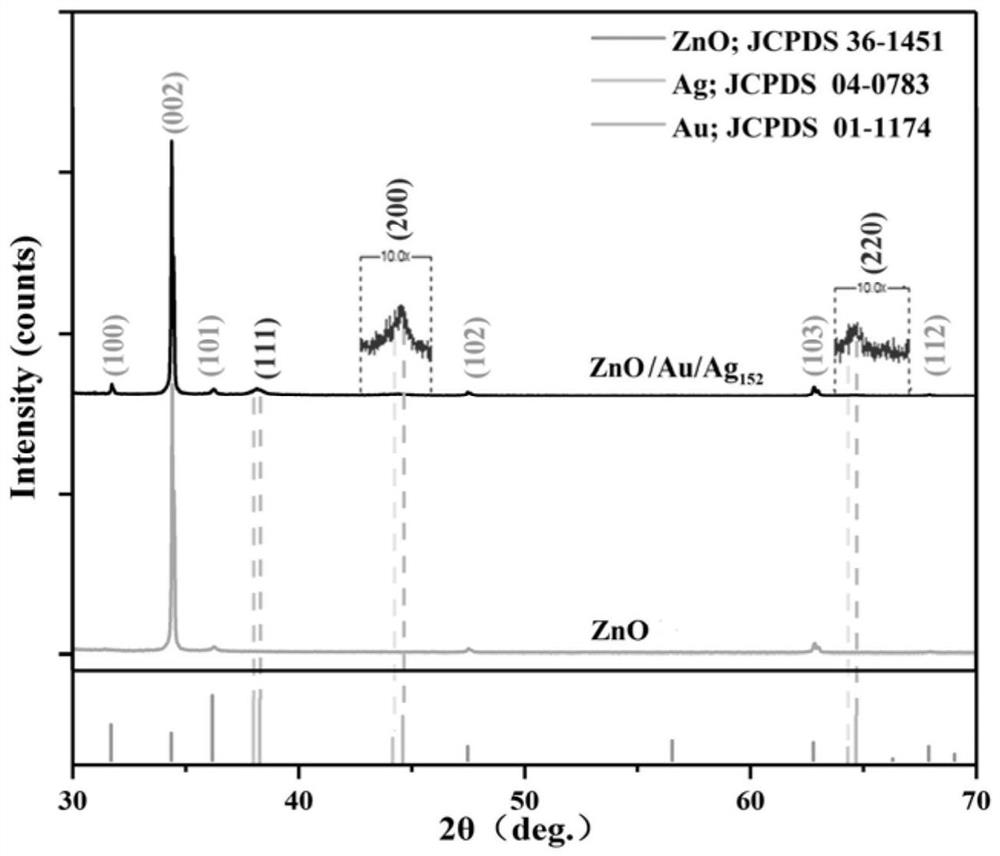

[0059] (1) Prepare 5×10 -4 M crystal violet aqueous solution, take 10 μL and drop it on ZnO array, ZnO / AuNPs substrate, ZnO / Au / Ag 152 The surface of the three-dimensional SERS substrate was dried for SERS detection (the Raman spectrometer was Derbyshire, and the excitation wavelength was 785nm). see test results Image 6 , by comparison, it can be found that the deposition of AuNPs has greatly improved the SERS signal intensity of the three-dimensional ZnO array. Subsequently, Ag 152 (SCH 2 CH 2 Ph) 60 With the deposition of nanoclusters, the intensity of SERS signal was further enhanced. It can be seen that the nanoclusters have greatly enhanced the SERS performance of the substrate.

[0060] (2) Prepare 5×10 -3 to 5×10 -12Rhodamine B aqueous solution of M for testing ZnO / AuNPs substrates and ZnO / Au / Ag 152 Detection limits for 3D SER...

Embodiment 3

[0067] The recyclability of the novel 3D substrate was evaluated using rhodamine 6G molecule.

[0068] (2) Prepare 1×10 -6 M of rhodamine 6G aqueous solution, take 2mL of the solution in a cuvette, use an ultraviolet absorbance photometer (UV-6300, MAPADA) to detect the absorbance, and record. Subsequently, under the assisted condition of ZnO / AuNPs substrate, the degradation reaction was carried out for 90min under the ultraviolet light (~254nm, 8w), and the absorbance of the solution was detected every ten minutes, and recorded. Such as Figure 9 As shown, with the prolongation of the ultraviolet radiation time, the absorbance of rhodamine 6G aqueous solution gradually decreases. At the same time, it can be seen in the inserted figure that the color of rhodamine 6G aqueous solution gradually becomes lighter, which also shows that rhodamine 6G molecules are assisted on the ZnO / AuNPs substrate. gradually degrades under these conditions.

[0069] (2) Using the same experiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com