Supercapacitor electrode material and preparation method and application thereof

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, chemical instruments and methods, inorganic chemistry, etc. The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

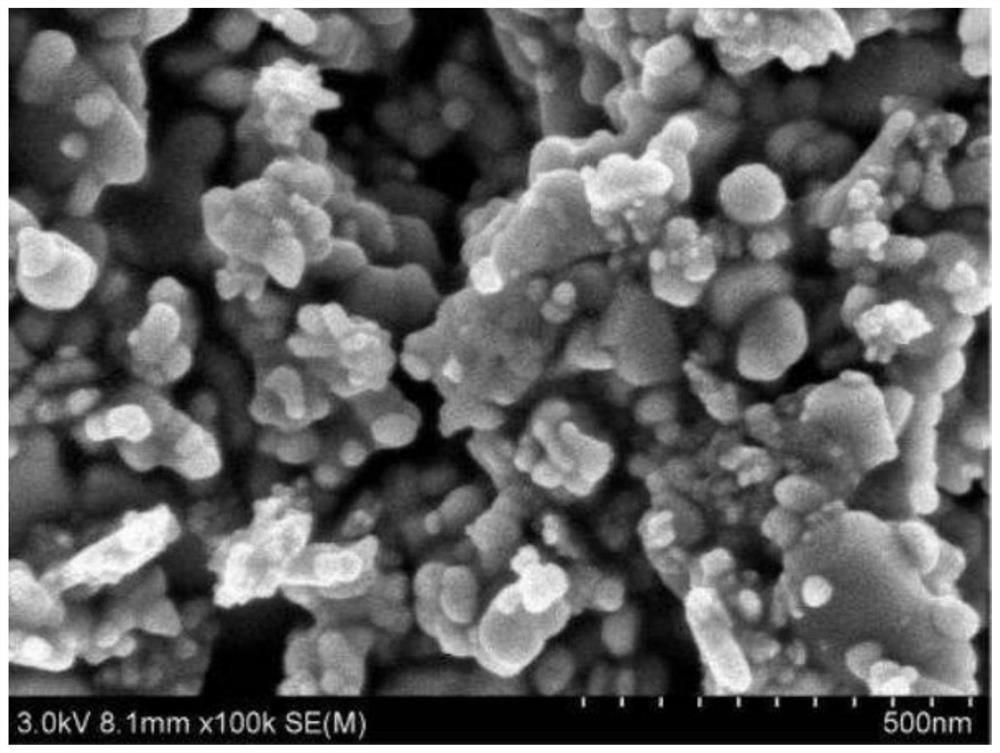

Image

Examples

Embodiment 1

[0029] A preparation method for a supercapacitor electrode material, comprising the steps of:

[0030] (1) Add manganese sulfate and ammonium persulfate to deionized water, stir and mix evenly, then transfer to the reaction kettle, then place the reaction kettle in a hydrothermal reaction box, and conduct a hydrothermal reaction at 140°C for 4 hours. The product is centrifuged, washed, and dried to obtain sea urchin-like nano-α-MnO 2 ; Wherein, the mass volume ratio (g / ml) of manganese sulfate, ammonium persulfate and deionized water is 1:1.2:50;

[0031] (2) the sea urchin-shaped nano-α-MnO prepared in step (1) 2 Add it into deionized water, heat to 100°C for 1.5h, and then cool to room temperature, then add 3-chloropropyltrimethoxysilane, ultrasonically disperse the mixture for 5h at 80°C, and the reaction is over Afterwards, the product was centrifuged, washed, and dried to obtain chloropropyl-functionalized nano-MnO 2; Among them, sea urchin-like nano-α-MnO 2 And the m...

Embodiment 2

[0037] A preparation method for a supercapacitor electrode material, comprising the steps of:

[0038] (1) Add manganese sulfate and ammonium persulfate into deionized water, stir and mix evenly, then transfer to the reaction kettle, then place the reaction kettle in a hydrothermal reaction box, and conduct a hydrothermal reaction at 160°C for 3 hours. The product is centrifuged, washed, and dried to obtain sea urchin-like nano-α-MnO 2 ; Wherein, the mass volume ratio (g / ml) of manganese sulfate, ammonium persulfate and deionized water is 1:1.2:50;

[0039] (2) the sea urchin-shaped nano-α-MnO prepared in step (1) 2 Add it into deionized water, heat it to 90°C and stir it for 2 hours. After the treatment is completed, cool it to room temperature, then add 3-chloropropyltrimethoxysilane, ultrasonically disperse it evenly, and react the mixture at 90°C for 8 hours. The product was centrifuged, washed, and dried to obtain chloropropyl-functionalized nano-MnO 2 ; Among them, se...

Embodiment 3

[0045] A preparation method for a supercapacitor electrode material, comprising the steps of:

[0046] (1) Add manganese sulfate and ammonium persulfate to deionized water, stir and mix evenly, then transfer to the reaction kettle, then place the reaction kettle in a hydrothermal reaction box, and conduct a hydrothermal reaction at 150°C for 4 hours. The product is centrifuged, washed, and dried to obtain sea urchin-like nano-α-MnO 2 ; Wherein, the mass volume ratio (g / ml) of manganese sulfate, ammonium persulfate and deionized water is 1:1.2:50;

[0047] (2) the sea urchin-shaped nano-α-MnO prepared in step (1) 2 Add it into deionized water, heat it to 100°C for 1.5h, and then cool it to room temperature, then add 3-chloropropyltrimethoxysilane, ultrasonically disperse the mixture at 80°C for 8h, and the reaction is over Afterwards, the product was centrifuged, washed, and dried to obtain chloropropyl-functionalized nano-MnO 2 ; Among them, sea urchin-like nano-α-MnO 2 An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com