A kind of preparation method of high temperature synthetic heat conduction oil

A heat-conducting oil and high-temperature technology, which is applied in the field of high-temperature synthetic heat-conducting oil preparation, can solve problems such as high operating temperature, inability to produce, and low saturated steam pressure, and achieve the effects of less reaction steps, low cost, and high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

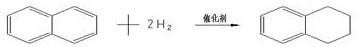

[0028] The synthesis of embodiment 1 tetrahydronaphthalene

[0029]

[0030] Put naphthalene into the autoclave, add 3.1% Raney nickel, after gas replacement, raise the temperature to 180°C and stir, then introduce hydrogen, the pressure is 3.0Mpa, after the reaction is completed, cool down to room temperature, remove Raney nickel, and rectify and separate of tetrahydronaphthalene.

Embodiment 2

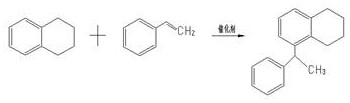

[0031] Example 2 Synthesis of heat transfer oil

[0032]

[0033]

[0034] Add 400g tetrahydronaphthalene in the reactor, add 1600g of carbon tetrachloride, add 12g of aluminum trichloride, stir, then dropwise add 226g of styrene, the dropping temperature is the reflux temperature of carbon tetrachloride, after the dropwise addition Heat preservation reaction for 3 hours, add 36g of water, then stand to separate layers, separate the water layer, and rectify and separate to obtain the finished product, which is analyzed by gas chromatography: 1,2,3,4-tetrahydro-1-(1-phenylethyl ) naphthalene and 1,2,3,4-tetrahydro-5-(1-phenylethyl)naphthalene ratio is 8:2, kinematic viscosity is 15mm 2 / S, the boiling point is 338°C under standard conditions, and the flash point (opening) is 196°C.

Embodiment 3

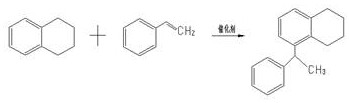

[0035] Example 3 Synthesis of heat transfer oil

[0036]

[0037]

[0038] Add 400g of tetrahydronaphthalene in the reactor, add 2400g of dichloroethane, add 20g of sulfuric acid, stir, then dropwise add 226g of styrene, the dropping temperature is the reflux temperature of carbon tetrachloride, after the dropping, keep warm for 3 hour, add 100g of water, then let stand to separate layers, separate the water layer, and rectify and separate to obtain the finished product, which is analyzed by gas chromatography: 1,2,3,4-tetrahydro-1-(1-phenylethyl)naphthalene and The ratio of 1,2,3,4-tetrahydro-5-(1-phenylethyl)naphthalene is 8:2, and the kinematic viscosity is 15mm 2 / S, the boiling point is 338°C under standard conditions, and the flash point (opening) is 196°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com