Mixed fermentation enzyme production process

A technology of mixed fermentation and process, applied in the field of fermentation, can solve problems such as environmental pollution, achieve the effect of low price and reduce the cost of enzyme production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of mixed fermentation enzyme production technology, it comprises the steps:

[0036] Preparation of Trichoderma reesei seed liquid: Inoculate Trichoderma reesei on PDA solid medium for cultivation to obtain a single colony; pick a single colony and inoculate it into PDA liquid medium for seed cultivation to obtain a concentration of 2 × 10 8 The Trichoderma reesei seed liquid of cfu / ml;

[0037] Preparation of Rhizopus stoloniferus seed solution: Inoculate Rhizopus stoloniferus on PDA solid medium and cultivate to obtain a single colony; pick a single colony and inoculate it on the seed medium for seed culture, and obtain a concentration of 5 × 10 8 The rhizopus stolonifera seed liquid of cfu / ml; The component of described seed culture medium is: glucose 1.5%, ammonium sulfate 0.4%, potassium dihydrogen phosphate 0.6%, corn steep liquor 2%, surplus is water, above is weight percentage;

[0038]Preparation of Bacillus pumilus seed solution: Inoculate Bacillus pu...

Embodiment 2

[0042] A kind of mixed fermentation enzyme production technology, it comprises the steps:

[0043] Preparation of Trichoderma reesei seed liquid: Inoculate Trichoderma reesei on PDA solid medium for cultivation to obtain a single colony; pick a single colony and inoculate it into PDA liquid medium for seed cultivation to obtain a concentration of 2 × 10 8 The Trichoderma reesei seed liquid of cfu / ml;

[0044] Preparation of Rhizopus stoloniferus seed solution: Inoculate Rhizopus stoloniferus on PDA solid medium and cultivate to obtain a single colony; pick a single colony and inoculate it on the seed medium for seed culture, and obtain a concentration of 5 × 10 8 The rhizopus stolonifera seed liquid of cfu / ml; The component of described seed culture medium is: glucose 1.5%, ammonium sulfate 0.4%, potassium dihydrogen phosphate 0.6%, corn steep liquor 2%, surplus is water, above is weight percentage;

[0045] Preparation of Bacillus pumilus seed solution: Inoculate Bacillus p...

Embodiment 3

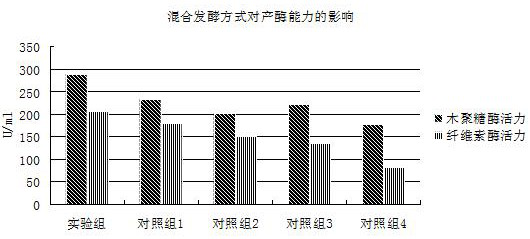

[0049] Effects of compatibility of different strains on enzyme activity:

[0050] The invention adopts the conventional 3,5-dinitrosalicylic acid method to detect the activity of xylanase and cellulase.

[0051] Group settings:

[0052] Experimental group: Example 1;

[0053] Control group 1: Simultaneous vaccination, the rest are the same as in Example 1;

[0054] Matched group 2: Trichoderma reesei+rhizoopsis stolonifer, all the other are with embodiment 1;

[0055] Control group 3: Trichoderma reesei+Bacillus pumilus, all the other are the same as embodiment 1;

[0056] Control group 4: Rhizopus stolonifer+Bacillus pumilus, all the other are with embodiment 1;

[0057] like figure 1 As shown, the fermentation enzyme activity of the experimental group was the highest, the xylanase activity reached 288U / ml, and the cellulase activity reached 206U / ml, which was significantly higher than that of the control group 1 inoculated at the same time, and the control group using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com