Method for separating and purifying trimethyl benzene from C9 heavy aromatics

A technology for separation and purification of trimethylbenzene, applied in the field of aromatic hydrocarbon separation, can solve problems such as low yield, and achieve the effect of high yield and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

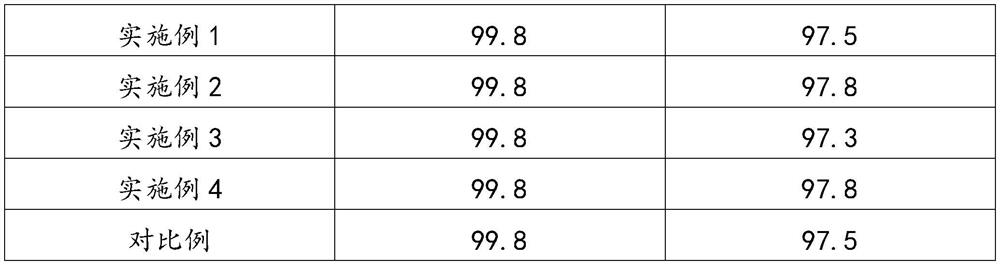

Examples

Embodiment 1

[0028](1) 10g graphene nanosheets and 100ml dehydrated alcohol are mixed and ultrasonically treated, and the graphene nanosheets after the treatment are placed in the mixed solution of 42ml magnesium chloride and aluminum chloride, and the concentrations of magnesium chloride and aluminum chloride in the mixed solution are respectively 2mol / L, 1mol / L, then slowly drop 12g15wt% urea solution and 10g5wt% polyvinyl alcohol solution, the rate of addition of urea solution, polyvinyl alcohol solution is controlled to be 1.55ml / min, 1.25ml / min; Under reflux for 15 hours, cool to room temperature after the reaction, filter the reaction liquid, wash the obtained solid and dry it, and finally place it in the air atmosphere of the muffle furnace, firstly raise the temperature to 300°C at a rate of 3°C / min, and keep it warm for 10min , and then heated up to 450°C at a rate of 7°C / min, and kept for 1h; a porous magnesium / aluminum metal oxide coating was prepared on the surface of the graphe...

Embodiment 2

[0034] (1) 10g graphene nanosheets and 100ml dehydrated alcohol are mixed and ultrasonically treated, and the graphene nanosheets after the treatment are placed in the mixed solution of 42ml magnesium chloride and aluminum chloride, and the concentrations of magnesium chloride and aluminum chloride in the mixed solution are respectively It is 3mol / L, 1mol / L, then slowly add dropwise 20g15wt% urea solution and 10g5wt% polyvinyl alcohol solution, the rate of addition of urea solution, polyvinyl alcohol solution is controlled as 1.55ml / min, 1.25ml / min; Under reflux for 20 hours, after the reaction, cool to room temperature, filter the reaction solution, wash and dry the obtained solid, and finally place it in the air atmosphere of the muffle furnace, first raise the temperature to 300°C at a rate of 3°C / min, and keep it for 10 minutes , and then heated up to 450°C at a rate of 7°C / min, and kept for 3h; a porous magnesium / aluminum metal oxide coating was prepared on the surface of ...

Embodiment 3

[0040] (1) 10g graphene nanosheets and 100ml dehydrated alcohol are mixed and ultrasonically treated, and the graphene nanosheets after the treatment are placed in the mixed solution of 42ml magnesium chloride and aluminum chloride, and the concentrations of magnesium chloride and aluminum chloride in the mixed solution are respectively Be 2mol / L, 1mol / L, then slowly drop 15g15wt% urea solution and 10g5wt% polyvinyl alcohol solution, the rate of addition of urea solution, polyvinyl alcohol solution is controlled as 1.55ml / min, 1.25ml / min; Under reflux for 15 hours, cool to room temperature after the reaction, filter the reaction liquid, wash the obtained solid and dry it, and finally place it in the air atmosphere of the muffle furnace, firstly raise the temperature to 300°C at a rate of 3°C / min, and keep it warm for 10min , and then heated up to 450°C at a rate of 7°C / min, and kept for 2h; a porous magnesium / aluminum metal oxide coating was prepared on the surface of the graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com