Para-aramid fiber, preparation method thereof and application of para-aramid fiber in preparation of molten metal splashing protective clothing

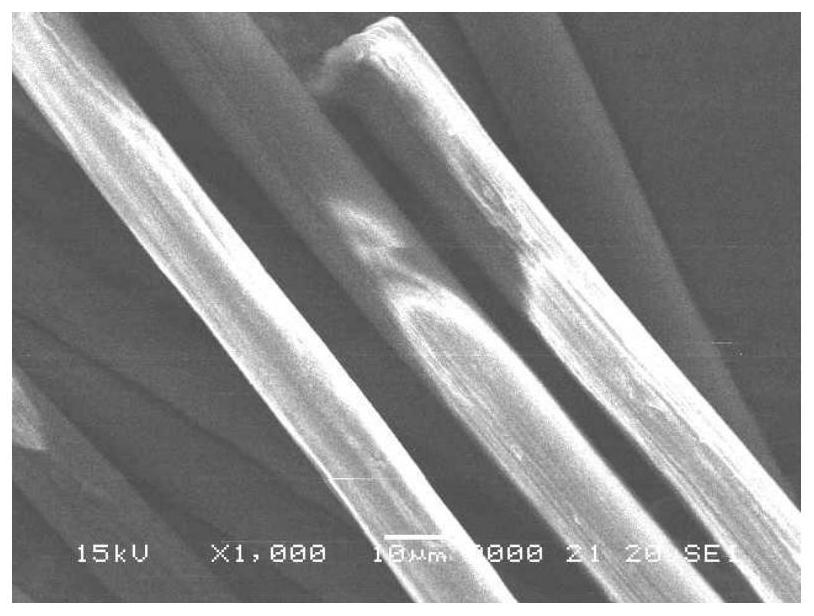

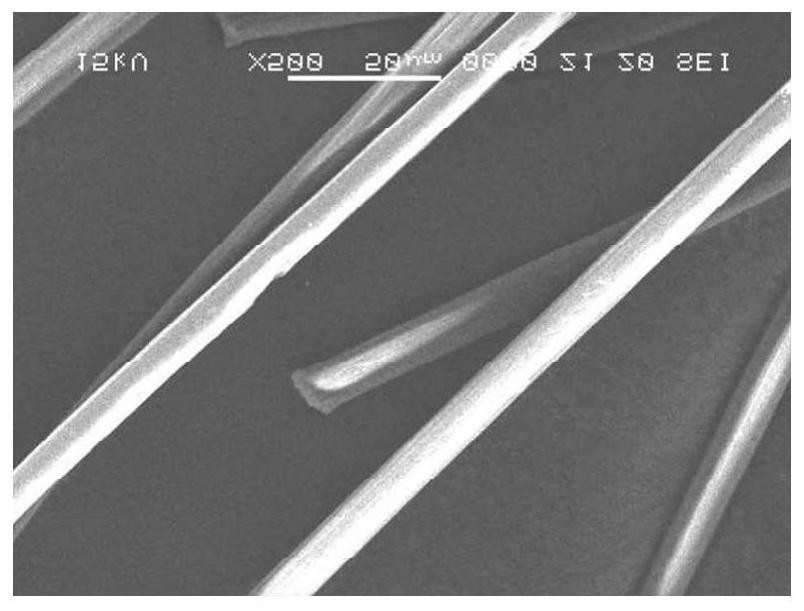

A para-aramid fiber and clothing technology, applied in fiber chemical characteristics, wet spinning, textiles and papermaking, etc., can solve the problems of poor smoothness and easy adhesion of aramid fiber, achieve perfect fiber surface, reduce Casualties, the effect of good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

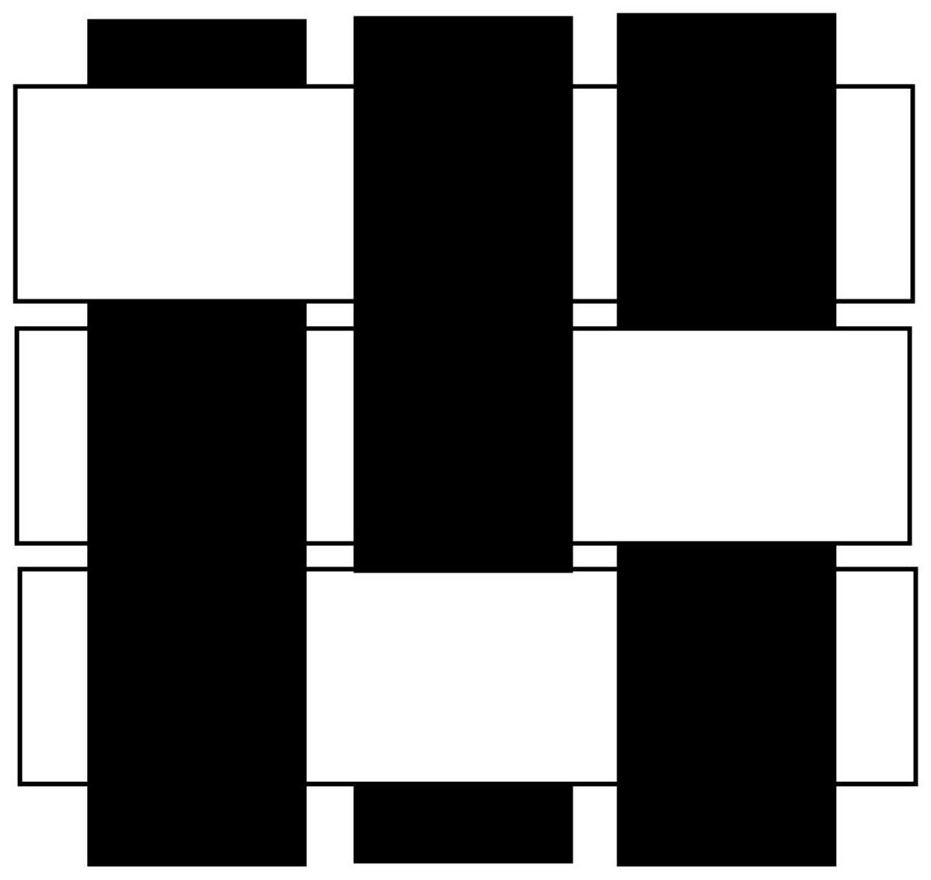

Image

Examples

Embodiment 1

[0039] A preparation method of para-aramid fibers, comprising the steps of:

[0040] Using N-methylpyrrolidone as a solvent, dissolve p-phenylenediamine into N-methylpyrrolidone, and then add terephthaloyl chloride, wherein the molar ratio of p-phenylenediamine to terephthaloyl chloride is 1:1 , dissolve and react for 50 minutes to obtain a mixed solution, then add triphenylmethane triisocyanate to the mixed solution, the amount of triphenylmethane triisocyanate added is 0.5% of the total mass of the mixed solution, and then polycondense at -10 to 10°C After reacting for 5 minutes, a poly-p-phenylene terephthalamide polymer raw material with an intrinsic viscosity of 6.5-7.5 dL / g was obtained.

[0041] (1) Add the poly-p-phenylene terephthalamide polymer raw material with an intrinsic viscosity of 6.5-7.5dL / g into concentrated sulfuric acid with a concentration of 99-101% and mix evenly, and control the temperature at 80-90°C after stirring. ℃, to prepare a mixed solution wit...

Embodiment 2

[0045] The amount of triphenylmethane triisocyanate added is 1% of the total mass of p-phenylenediamine, N-methylpyrrolidone and terephthaloyl chloride, and the remaining contents are the same as in Example 1.

Embodiment 3

[0047] The addition amount of triphenylmethane triisocyanate is 1.5% of the total mass of p-phenylenediamine, N-methylpyrrolidone and terephthaloyl chloride, and the remaining contents are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Average linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com