Preparation method of air purification filter fabric with formaldehyde removal function

A formaldehyde removal and fabric technology, applied in the field of textile materials, can solve the problem that bacteria and viruses cannot be effectively removed, and achieve the effect of promoting formaldehyde removal and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

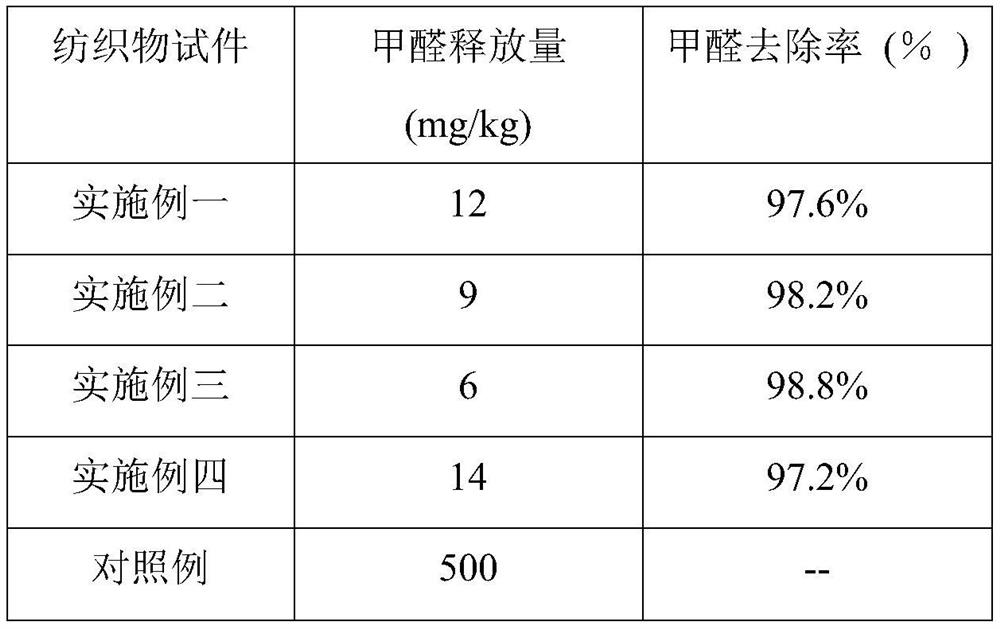

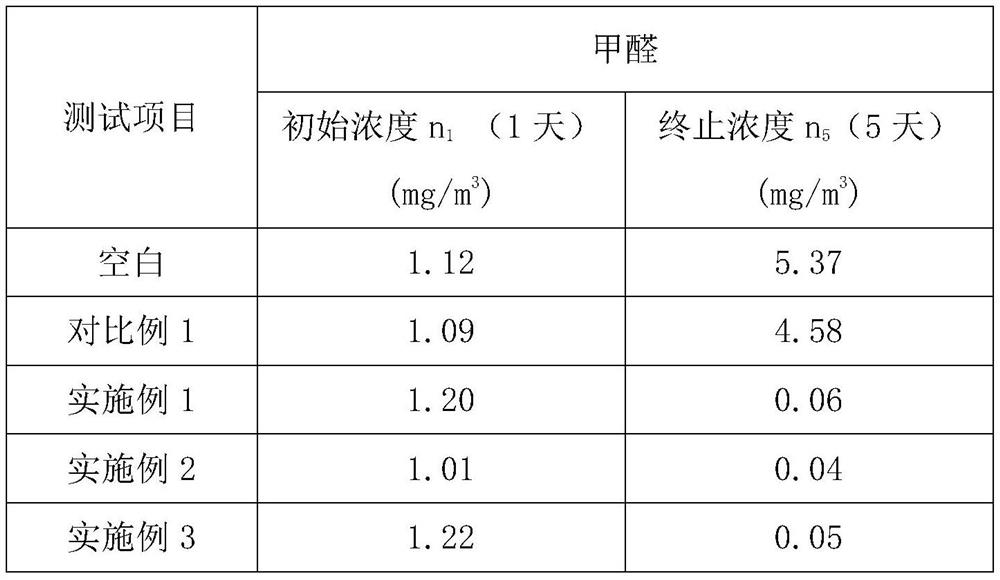

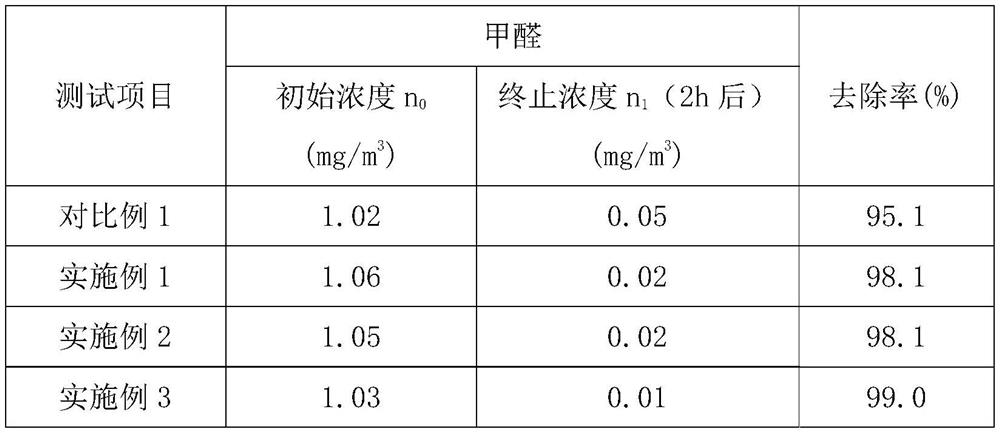

Examples

Embodiment 1

[0025] A method for preparing an air-clean filter fabric with formaldehyde removal function, comprising the following steps:

[0026] Step 1), prepare fabric treatment agent, mix and stir configuration by powder and liquid preparation;

[0027] The quality formula of the powder contains:

[0028] 20g of tea polyphenols, 10g of blueberry leaf polyphenols, 5g of ammonium alginate, 15g of polyvinyl alcohol, 0.5g of sodium dodecylsulfonate, nano-silica powder (white carbon black SiO with a content of more than 90%) 2 )5g;

[0029] 55.5 g of powder was obtained.

[0030] The quality formulation of the liquid formulation includes:

[0031] Acetic acid 10g, citric acid 3g, phosphoric acid 1g, ethanol 5g, nano-silica colloid (20% by mass) 20g, distilled water 15g;

[0032] 54 g of the liquid formulation was obtained.

[0033] Take 30g of the powder and add it to 15g of the liquid preparation, stir and mix evenly to obtain the fabric treatment agent.

[0034] Step 2), the prepara...

Embodiment 2

[0039] A method for preparing an air-clean filter fabric with formaldehyde removal function, comprising the following steps:

[0040] Step 1), preparing fabric treatment agent, which is prepared by mixing and stirring powder and liquid preparation;

[0041] The quality formula of the powder contains:

[0042] Tea polyphenols 30g, blueberry leaf polyphenols 15g, ammonium alginate 7g, polyvinyl alcohol 25g, sodium dodecylsulfonate 0.8g, nano-silica powder (using white carbon black SiO with a content of more than 90%) 2 )8g;

[0043] Obtained powder 85.8g.

[0044] The quality formulation of the liquid formulation includes:

[0045] Acetic acid 12g, citric acid 5g, phosphoric acid 2g, ethanol 8g, nano-silica colloid (30% by mass) 25g, distilled water 25g;

[0046] 77 g of a liquid formulation was obtained.

[0047] Take 50g of the powder and add it to 10g of the liquid preparation, stir and mix evenly to obtain the fabric treatment agent.

[0048] Step 2), the preparation o...

Embodiment 3

[0053] A method for preparing an air-clean filter fabric with formaldehyde removal function, comprising the following steps:

[0054] Step 1), prepare fabric treatment agent, mix and stir configuration by powder and liquid preparation;

[0055] The quality formula of the powder contains:

[0056] 40g of tea polyphenols, 20g of blueberry leaf polyphenols, 8g of ammonium alginate, 30g of polyvinyl alcohol, 1g of sodium dodecylsulfonate, nano-silica powder (using more than 90% white carbon black SiO 2 )10g;

[0057] 109 g of powder was obtained.

[0058] The quality formulation of the liquid formulation includes:

[0059] Acetic acid 15g, citric acid 6g, phosphoric acid 3g, ethanol 10g, nano silica colloid (40% by mass) 30g, distilled water 45g;

[0060] 109 g of a liquid formulation was obtained.

[0061] Take 72g of powder and add it to 9g of liquid preparation, stir and mix evenly to obtain fabric treatment agent.

[0062] Step 2), preparation of formaldehyde catalytic d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com