Super-amphiphobic coating on surface of heat exchange tube, preparation technology of super-amphiphobic coating and application of super-amphiphobic coating to methanol-to-olefin device

A preparation process and technology for heat exchange tubes, applied in the direction of surface coating liquid devices, coatings, special surfaces, etc., can solve problems such as clogged equipment, frequent parking to remove wax, and easy wax deposition in heat exchangers, etc., to achieve reduction Brittleness, effect of increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

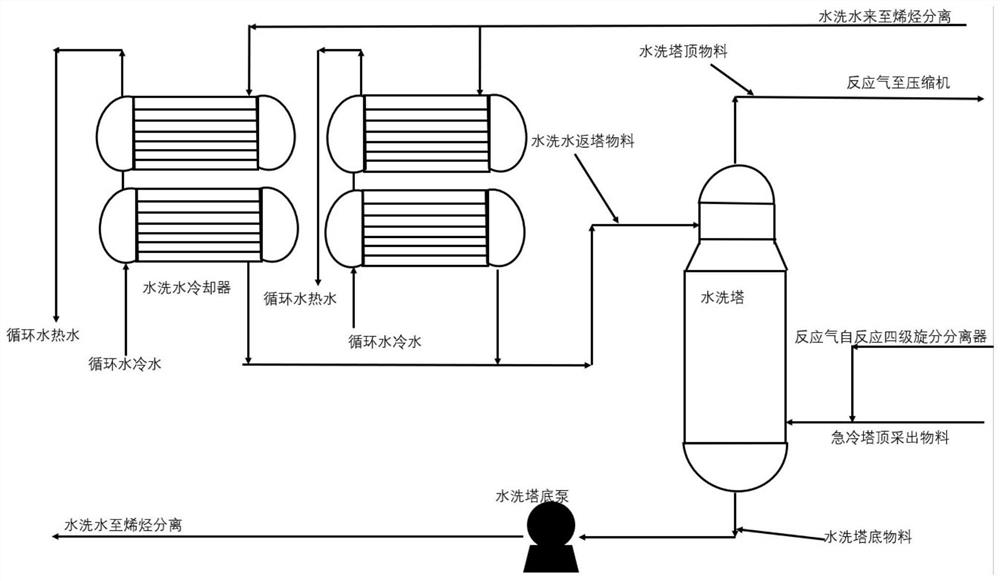

Method used

Image

Examples

Embodiment 1

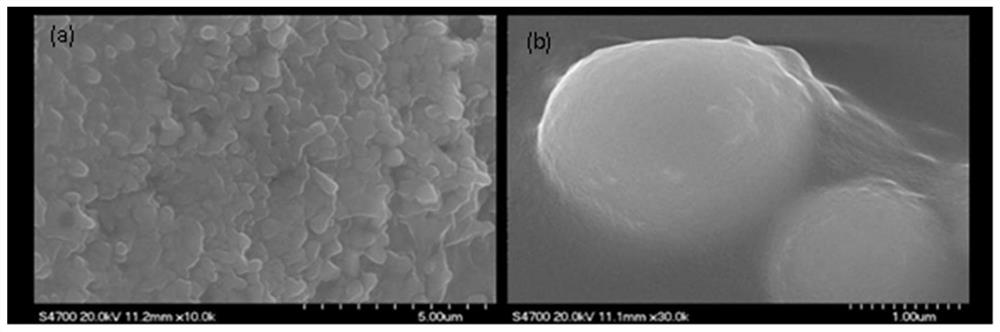

[0034] (1) Put the heat exchange tube in a 1mol / L NaOH solution, soak for 3 hours, neutralize it with a 0.5mol / L hydrochloric acid solution, rinse it with tap water 5 times, and dry it in a nitrogen atmosphere;

[0035](2) Place the outer surface of the heat exchange tube under a high-speed sandblasting machine for sandblasting to remove surface impurities and roughen the surface;

[0036] (3) Spray fluorine-containing paint evenly on the outer surface of the heat exchange tube at 0.5 MPa to form a 20-50 μm thick coating to enhance its adhesion. At the same time, ensure that the composite coating powder can evenly adhere to the outer surface of the heat exchange tube ; The fluorine content in the fluorine paint is 25%;

[0037] (4) Add 2g of ethylene chlorotrifluoroethylene copolymer to 60ml of ethyl acetate solution, stir ultrasonically for 20min, then add 0.4g SiO2 / ZnO composite particles and 0.08g polyaniline, stir ultrasonically for 1h, and disperse the mixture evenly , t...

Embodiment 2

[0040] (1) Put the heat exchange tube into 0.3mol / L NaOH solution, soak for 4h, neutralize with 0.5mol / L hydrochloric acid solution, rinse with tap water 4 times, and dry in nitrogen atmosphere;

[0041] (2) Place the outer surface of the heat exchange tube under a high-speed sandblasting machine for sandblasting to remove surface impurities and roughen the surface;

[0042] (3) Spray fluorine-containing paint evenly on the outer surface of the heat exchange tube at 0.7 MPa to form a 20-50 μm thick coating to enhance its adhesion, and at the same time, ensure that the composite coating powder can evenly adhere to the outer surface of the heat exchange tube ; The fluorine content in the fluorine-containing paint is 27%;

[0043] (4) Add 5g of ethylene chlorotrifluoroethylene copolymer to 150ml of ethyl acetate solution, stir ultrasonically for 20min, then add 1.0g SiO2 / ZnO composite particles and 0.2g polyaniline, stir ultrasonically for 3h, and disperse the mixture evenly , t...

Embodiment 3

[0046] (1) Put the heat exchange tube into 0.7mol / L NaOH solution, soak for 3.5h, neutralize with 0.5mol / L hydrochloric acid solution, rinse with tap water 3 times, and dry in nitrogen atmosphere;

[0047] (2) Place the outer surface of the heat exchange tube under a high-speed sandblasting machine for sandblasting to remove surface impurities and roughen the surface;

[0048] (3) Spray the fluorine-containing paint evenly on the outer surface of the heat exchange tube at 0.6 MPa to form a 20-50 μm thick coating to enhance its adhesion. At the same time, ensure that the composite coating powder can evenly adhere to the outer surface of the heat exchange tube ; The fluorine content in the fluorine paint is 29%;

[0049] (4) Add 10g of ethylene chlorotrifluoroethylene copolymer to 150ml of ethyl acetate solution, stir ultrasonically for 30min, then add 2.0g SiO2 / ZnO composite particles and 0.4g polyaniline, and stir ultrasonically for 2h to disperse the mixture evenly , to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com