Tung oil hyperbranched polyester plasticizer as well as preparation method and application thereof

A hyperbranched polyester and plasticizer technology, which is applied in the preparation of carboxylate esters, chemical instruments and methods, and the preparation of organic compounds, can solve unsustainable problems, achieve low production costs, good heat resistance, and stable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

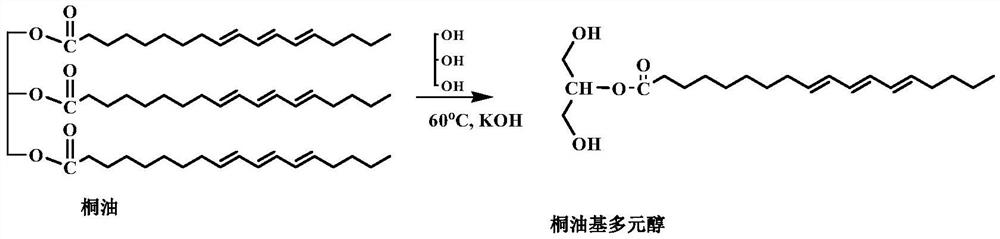

[0027] Synthesis of tung oil polyols:

[0028] In the embodiment of the present invention, the synthesis method of tung oil-based hyperbranched polyol needs to go through the following process: add 0.3mol tung oil and 0.75mol glycerin to a 500mL three-neck round bottom flask equipped with a reflux condenser, feed nitrogen, and heat up to 100 ℃ and keep stirring for 0.5 hours, then cool down to 80°C, add 0.1wt.% sodium methoxide (according to the mass of tung oil), continue to stir and react for 6 hours, stop the reaction and cool to room temperature, use dichloromethane to dissolve, and then use distilled water Washed 3 times, dried over anhydrous sodium sulfate, and removed dichloromethane by rotary evaporation to obtain tung oil-based hyperbranched polyol.

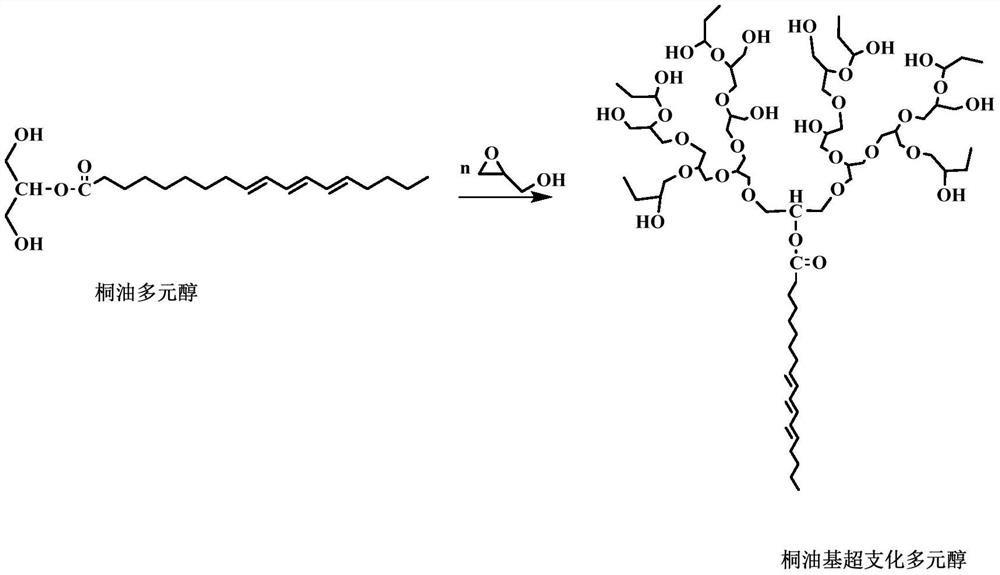

[0029] Synthesis of tung oil-based hyperbranched polyols:

[0030] Add 0.2 mol of tung oil-based hyperbranched polyol and 0.03 mol of potassium methoxide to a 500 mL three-neck round bottom flask equipped with a reflux ...

Embodiment 2

[0034] Synthesis of tung oil polyols:

[0035] In the embodiment of the present invention, the synthesis method of tung oil-based hyperbranched polyol needs to go through the following process: add 0.3mol tung oil and 0.9mol glycerin to a 500mL three-necked round bottom flask equipped with a reflux condenser, feed nitrogen, and heat up to 100 ℃ and continued to stir for 0.5 hours, then cooled to 60°C, added 1wt.% sodium methoxide (according to the mass of tung oil), continued to stir and react for 12 hours, stopped the reaction and cooled to room temperature, dissolved in dichloromethane, and washed with distilled water 3 times, dried over anhydrous sodium sulfate, and removed dichloromethane by rotary evaporation to obtain tung oil-based hyperbranched polyols.

[0036] Synthesis of tung oil-based hyperbranched polyols:

[0037] Add 0.2 mol of tung oil-based hyperbranched polyol and 0.04 mol of potassium methoxide to a 500 mL three-necked round bottom flask equipped with a re...

Embodiment 3

[0041] Synthesis of tung oil polyols:

[0042]In the embodiment of the present invention, the synthesis method of tung oil-based hyperbranched polyol needs to go through the following process: add 0.3mol tung oil and 0.9mol glycerin to a 500mL three-necked round bottom flask equipped with a reflux condenser, feed nitrogen, and heat up to 100 ℃ and continued to stir for 0.5 hours, then cooled to 60°C, added 1wt.% sodium methoxide (according to the mass of tung oil), continued to stir and react for 12 hours, stopped the reaction and cooled to room temperature, dissolved in dichloromethane, and washed with distilled water 3 times, dried over anhydrous sodium sulfate, and removed dichloromethane by rotary evaporation to obtain tung oil-based hyperbranched polyols.

[0043] Synthesis of tung oil-based hyperbranched polyols:

[0044] Add 0.2 mol of tung oil-based hyperbranched polyol and 0.04 mol of potassium methoxide to a 500 mL three-necked round bottom flask equipped with a ref...

PUM

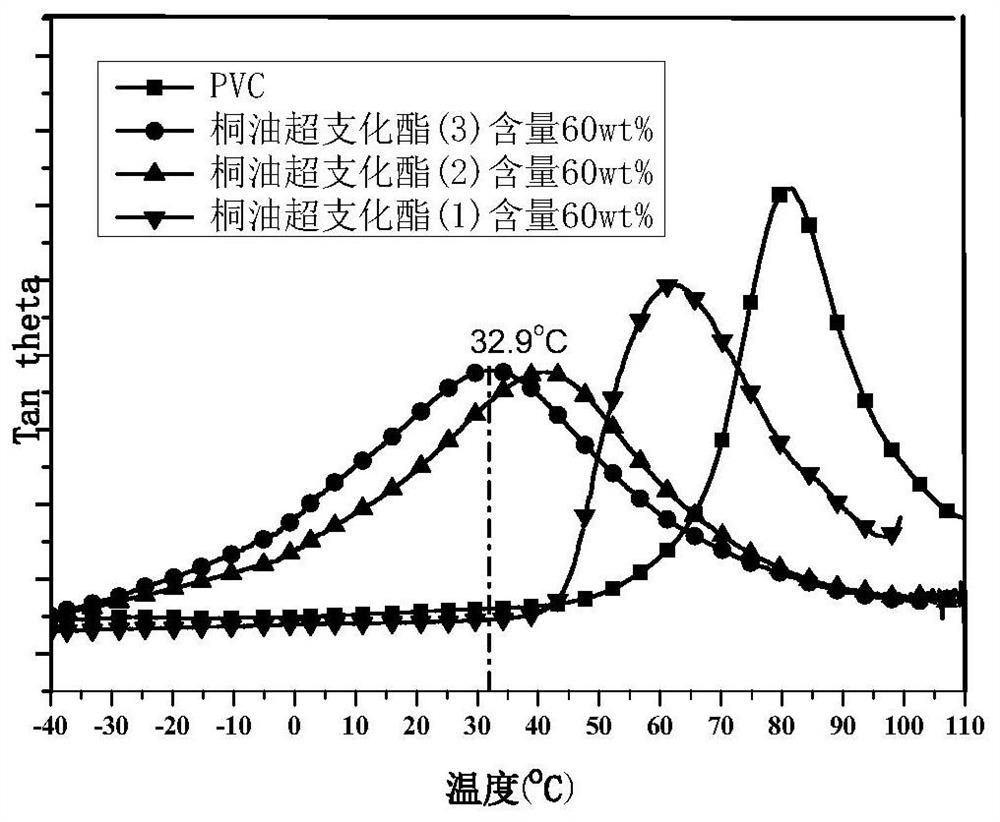

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com