Preparation method of continuous silicon carbide micro-nano fiber bundle

A technology of micro-nano fiber and silicon carbide, which is applied in the direction of fiber processing, yarn, artificial filament of inorganic raw materials, etc., can solve the problems of limiting the application level of materials, and the lack of silicon carbide micro-nano fiber bundles, etc., to achieve high degree of orientation and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

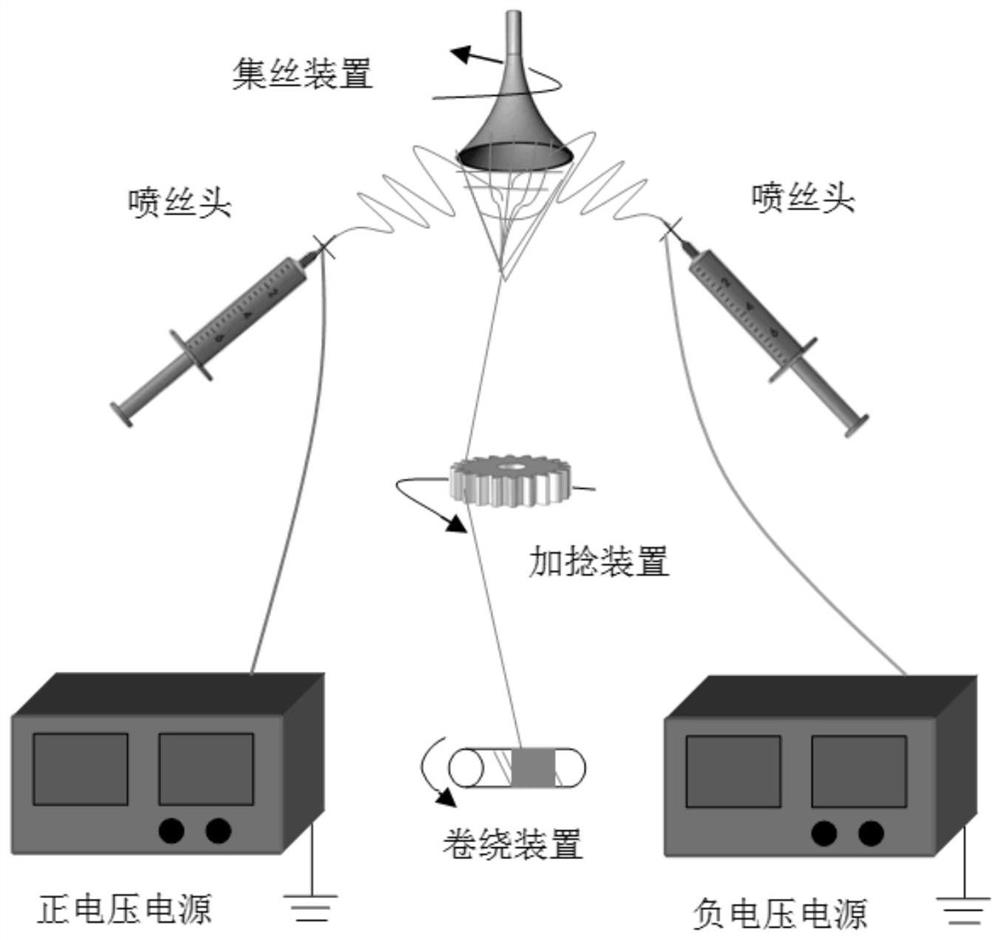

[0021] The invention provides a method for preparing continuous silicon carbide micro-nano fiber bundles, wherein the method comprises the following steps:

[0022] (1) Precursor synthesis: Synthesis of polyaluminocarbosilane;

[0023] (2) preparing an electrospinning solution: dissolving the polyaluminocarbosilane in a solvent, fully stirring, standing for defoaming, and obtaining an electrospinning solution of a uniform spinning system, and storing it for later use;

[0024] (3) Preparation of precursor fiber bundle: extract the first electrospinning solution with the first syringe, and extract the second electrospinning solution with the second syringe, the first electrospinning solution and the second electrospinning solution come from The electrospinning solution in the same spinning system or different spinning systems, that is, the components of the first electrospinning solution and the second electrospinning solution are the same or different;

[0025] The first inje...

Embodiment 1

[0047] Using polydimethylsiloxane (PDMS) as a raw material, cracking and rearranging at 450 ° C to obtain liquid polysiloxane (PSCS). Then polysilane (PSCS) and aluminum acetylacetonate were mixed at a mass ratio of 50:1, reacted at 550°C for 10 hours, cooled, and distilled to obtain a PACS solid resin.

[0048] And then PACS is dissolved in the mixed solvent and is mixed with the electrospinning solution of polyaluminocarbosilane (PACS), wherein, in the solvent, DMF:THF:xylene is 30%: 20%: 50%, and the concentration of electrospinning solution is 0.5 g / ml.

[0049] Then carry out electrospinning, wherein the solution consumption is 10ml, the metal hollow needle of syringe selects 8# needle head, and the inclination angles of two needles connected with high voltage positive power supply and high voltage negative power supply are respectively 0° and 15°, and the voltage is respectively 18kV and -18kV, the extrusion rate is 0.8ml / h and 1.0ml / h respectively.

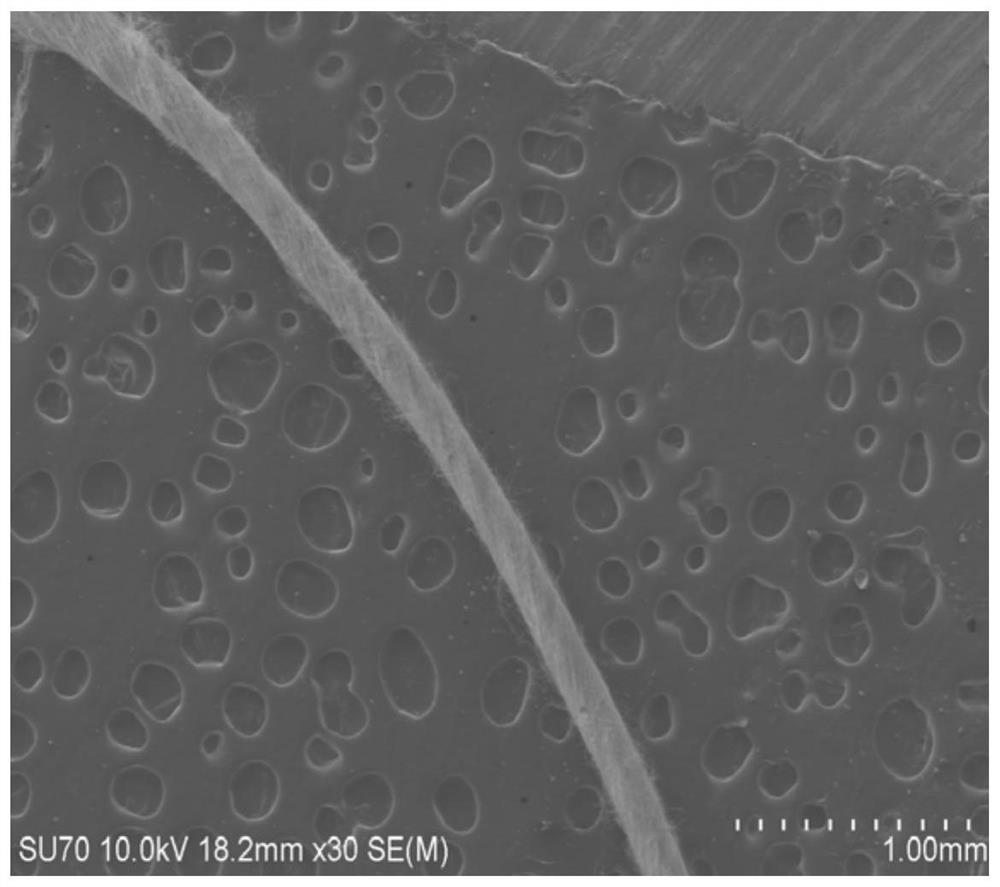

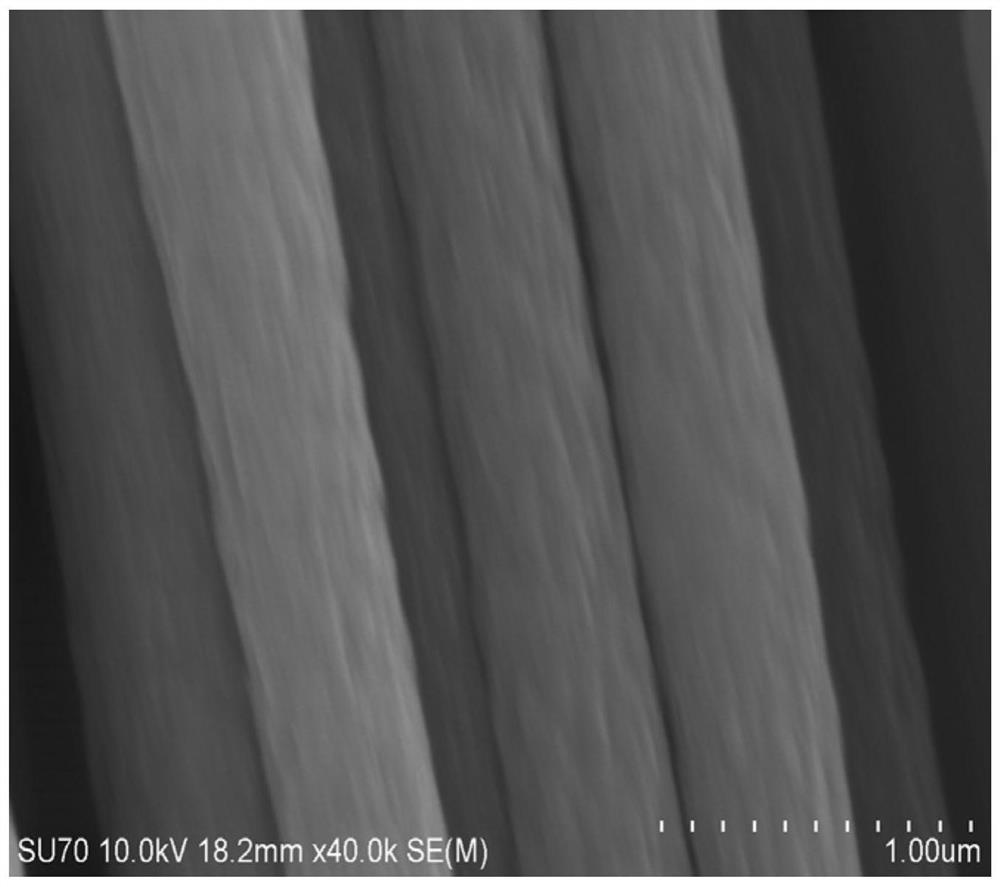

[0050] After the ...

Embodiment 2

[0054] Silicon carbide micro-nano fiber bundles were prepared in the same manner as in Example 1, except that the ratio of the mixed solvent was DMF:THF:xylene=20%:30%:50%. As a result, continuous silicon carbide micro-nano fiber bundles with an average diameter of 600 nm, a wire diameter of 200 microns, an average length of 30 m and an average specific surface area of 10 square meters per gram were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com