Method for preparing nanometer calcium carbonate from calcium-containing solid waste residues and waste acid

A technology of nano-calcium carbonate and solid waste residues, applied in the fields of calcium carbonate/strontium/barium, chemical instruments and methods, nanotechnology for materials and surface science, etc. and other problems, to achieve the effect of low cost, high economic benefit and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

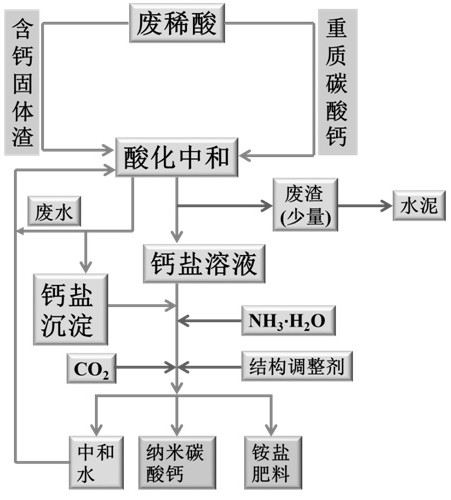

Method used

Image

Examples

Embodiment 1

[0033] The method for preparing nano-calcium carbonate by using calcium-containing solid waste residue and waste acid, the steps are as follows:

[0034] Weigh 1000g of calcium-containing solid waste residue (200 mesh), slowly add it to 25wt% waste hydrochloric acid with vigorous stirring, and when the pH ≈ 6.5, filter the insoluble matter and send it to make cement, and then add water to the solution to adjust the Ca 2+ The concentration is 0.1mol / L. Take 200 mL of the above 0.1 mol / L Ca salt solution, add 6 mL of 25 wt % concentrated ammonia water to adjust the pH to 9. Add 2 mL of ethylene glycol, and then at 20 °C, pass in CO at a rate of 60 mL / min 2 Gas for 45 minutes, after the reaction, undergo solid-liquid separation to obtain nanometer calcium carbonate solid and ammonium chloride solution. Calcium carbonate solid was dried at 110°C to be 1.97g, and the measured purity was 96%. After the filtrate was adjusted to neutral with dilute hydrochloric acid, it was dried a...

Embodiment 2

[0036] The method for preparing nano-calcium carbonate by using calcium-containing solid waste residue and waste acid, the steps are as follows:

[0037] Weigh 1000g of calcium-containing solid waste residue (200 mesh), slowly add it to 25wt% waste nitric acid with vigorous stirring, and when the pH ≈ 7.5, filter the insoluble matter and send it to make cement, and then add water to the solution to adjust the Ca 2+ The concentration is 0.1mol / L. Take 200 mL of the above 0.1 mol / L Ca salt solution, add 6 mL of 25 wt % concentrated ammonia water to adjust the pH to 8. Add 2 mL of ethylene glycol, then at 60 °C, pass CO at a rate of 300 mL / min 2 Gas for 15 minutes, after the reaction, undergo solid-liquid separation to obtain nano-calcium carbonate solid and ammonium nitrate solution. Calcium carbonate solid was dried at 110°C to obtain 2.04g, and the measured purity was 94%. After the filtrate was adjusted to neutral with dilute nitric acid, it was dried at 105°C to obtain am...

Embodiment 3

[0039] The method for preparing nano-calcium carbonate by using calcium-containing solid waste residue and waste acid, the steps are as follows:

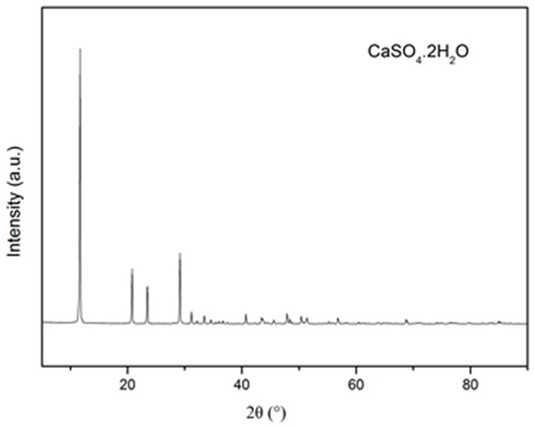

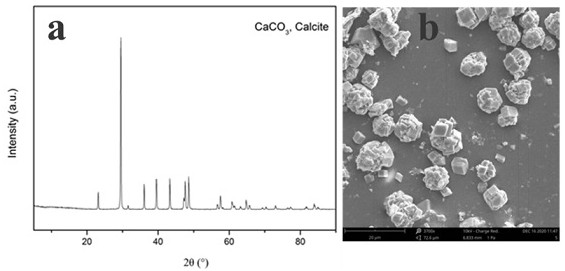

[0040] Weigh 1000g of calcium-containing solid waste residue (200 mesh), slowly add it to 25wt% waste sulfuric acid with vigorous stirring, and when the pH ≈ 6.5, filter the insoluble matter to obtain calcium sulfate solid ( figure 2 ), and the remaining wastewater will continue to be used for acidification and neutralization. Take 100 g of the above-mentioned calcium sulfate solid and place it in 200 mL of water, add 6 mL of 25 wt % concentrated ammonia water to adjust the pH to 8. Add 2 mL of structural regulator ethylene glycol, and then at 40 °C, pass CO at a rate of 150 mL / min. 2 Gas for 25 minutes, after the reaction, through solid-liquid separation, to obtain calcite-type nano-calcium carbonate solid ( image 3 ) and ammonium sulfate solution. Calcium carbonate solid was dried at 110°C to be 1.98g, and the measured purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com