Preparation method of methylene methanedisulfonate

A technology of methylene disulfonate and methylene disulfonyl chloride, applied in the direction of organic chemistry, etc., can solve the problems of low efficiency of methylene disulfonate, achieve high product yield, high economic benefit, meet the Apply the desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of preparation method of methylene disulfonate, concrete operation steps are: take by weighing 70.3g methylene disulfonyl chloride, 112.1g dichloromethane, 91.2g potassium carbonate, 1.6g DMAP join in the 500ml there-necked bottle, pass Into a dry and stable nitrogen flow, the reaction system was stirred at 10°C for 12h, and then filtered; the filter cake was extracted with 200g of dimethyl carbonate, the insoluble matter was removed by filtration, the filtrate was distilled to remove the solvent until a white solid was precipitated, then cooled to 5°C and stirred for 0.5 h Filtration gave 42.4 g of white crystal methylene disulfonate.

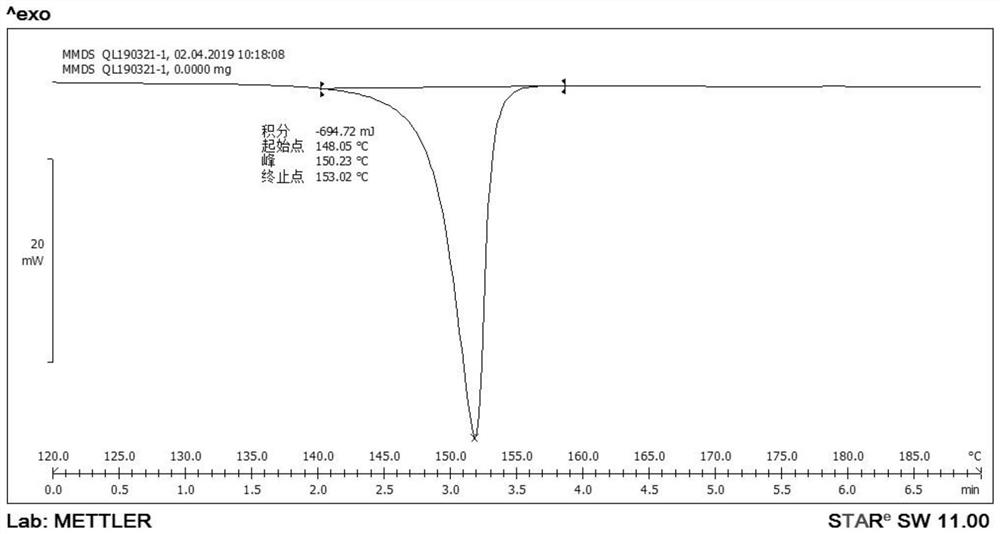

[0021] 99.7% detected by GC, the yield is 68.3%. The melting point is 148.05-153.02°C.

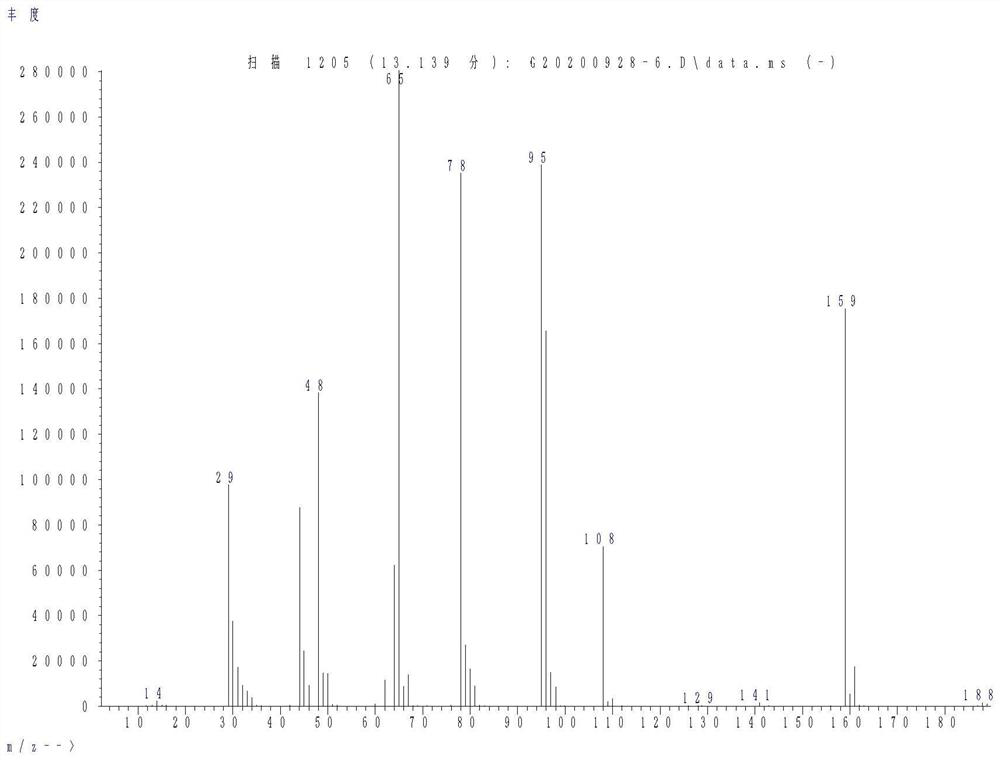

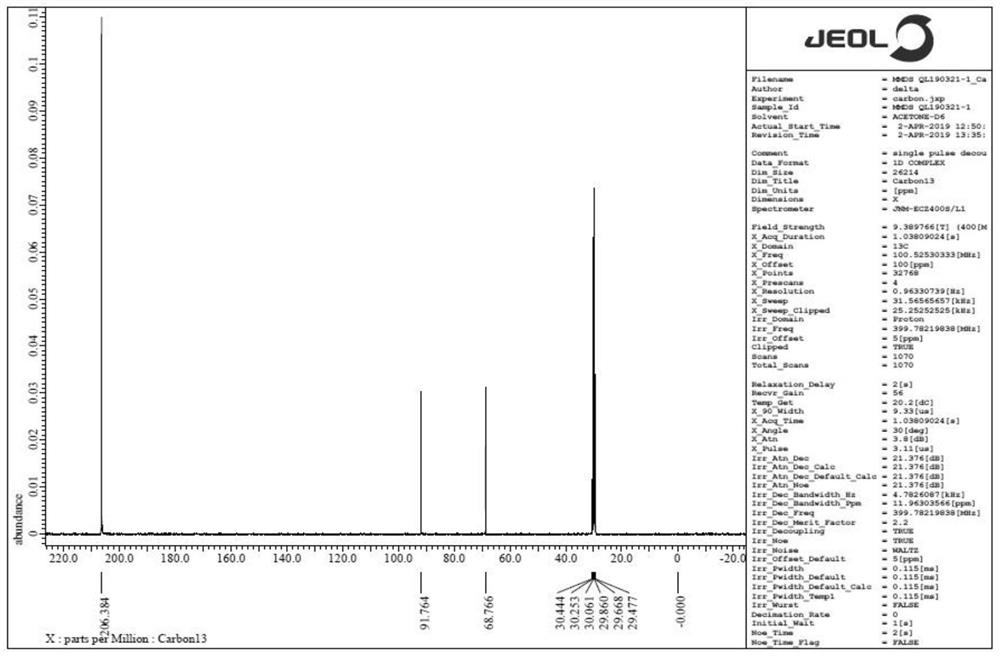

[0022] 1 HNMR (400MHZ, deuterated acetone) δ (ppm): 5.82 (s, 2H), 6.19 (s, 2H); 13CNMR (100MHZ, deuterated acetone) δ (ppm): 68.76, 91.76.HRMS (ESI) for C2H4O6S2 ,calcd:188,found:188.

Embodiment 2

[0024] A kind of preparation method of methylene disulfonate, concrete operation steps are: take by weighing 42.6g methylene disulfonyl chloride, 67.9g dichloromethane, 53g sodium carbonate, 1.2g DMAP join in the 500ml there-necked flask, pass into Dry and stable nitrogen flow, the reaction system was stirred at 30°C for 12h, then filtered; the filter cake was extracted with 230g of ethyl acetate, filtered to remove insoluble matter, the filtrate was distilled to remove solvent until a white solid was precipitated, then cooled to -5°C, stirred for 0.5h and filtered , The filter cake was dried to obtain 23.8 g of white crystal methylene disulfonate.

[0025] GC detection 99.6%, the yield is 63.2%. The melting point is 148.05-153.02°C.

[0026] 1 HNMR (400MHZ, deuterated acetone) δ (ppm): 5.82 (s, 2H), 6.19 (s, 2H); 13CNMR (100MHZ, deuterated acetone) δ (ppm): 68.76, 91.76.HRMS (ESI) for C2H4O6S2 ,calcd:188,found:188.

Embodiment 3

[0028] A preparation method of methylene disulfonate, the specific operation steps are: Weigh 70.3 methylene disulfonyl chloride, 168.2 g dichloromethane, 268.8 g cesium carbonate, 2.0 g DMAP into a 500 ml three-necked bottle, pass into Stir the reaction system at 40°C for 12 hours in a dry and stable nitrogen flow, then filter; use 400g of ethyl acetate to extract the filter cake, filter to remove insoluble matter, distill the filtrate to remove the solvent until a white solid is precipitated, then cool down to -10°C and stir for 0.5h Filter and dry the filter cake to obtain 48.2 g of white crystal methylene disulfonate.

[0029] GC detection 99.7%, the yield is 77.6%. The melting point is 148.05-153.02°C.

[0030] 1 HNMR (400MHZ, deuterated acetone) δ (ppm): 5.82 (s, 2H), 6.19 (s, 2H); 13CNMR (100MHZ, deuterated acetone) δ (ppm): 68.76, 91.76.HRMS (ESI) for C2H4O6S2 ,calcd:188,found:188.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com