Plating solution wastewater treatment method for nickel plating of plated part

A wastewater treatment and nickel plating technology, which is applied in metallurgical wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of high investment cost, complex treatment, secondary pollution of wastewater, etc. in the exchange process, and achieve oxidation and broken network High efficiency, improved oxidizing ability, strong oxidizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

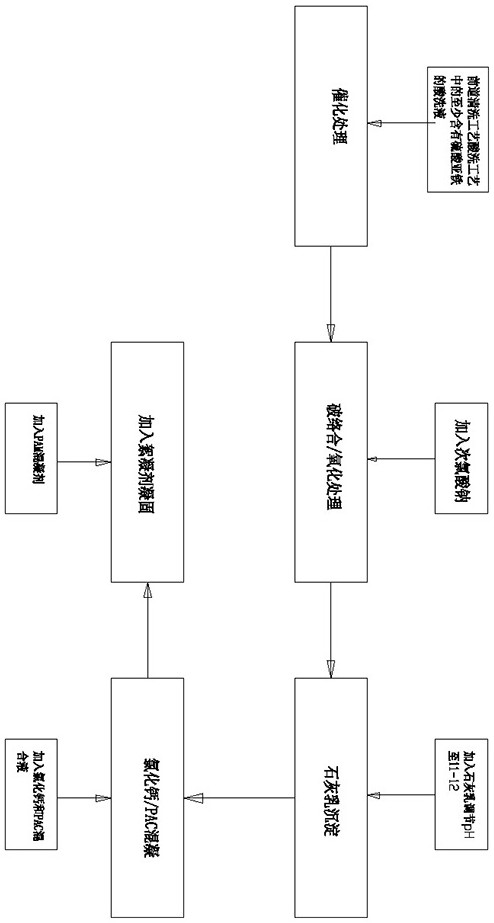

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (laboratory)

[0034] The influent water quality of the electroless plating wastewater to be treated is as follows: the pH of the wastewater is 6.3, the total nickel content is 90 mg / L, and the total phosphorus content is 150 mg / L.

[0035] Treatment process: Add 1ml of production line pickling solution (ferrous sulfate solution) dropwise to 500mL of the above-mentioned nickel post-reaction tank water (the pH of the wastewater is 6.3, the total nickel content is 90mg / L, and the total phosphorus content is 150mg / L). Stir for 10 minutes, and when the pH becomes about 4, add 5mL of sodium hypochlorite and stir for 6h; then add 7.5mL of milk of lime (Ca(OH)2 solution) and stir for 2h; then add 5mL of CaCl2 / PAC solution, stir for 5min and then add 5mL PAM, stirred slowly and waited for precipitation, then took the supernatant for detection.

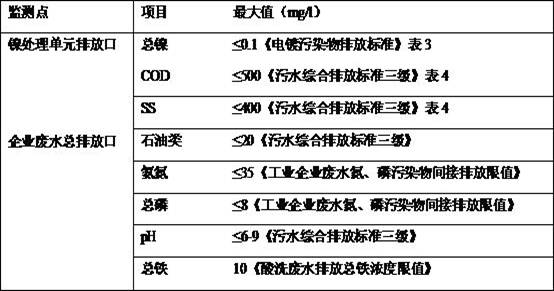

[0036] It can be seen from the test that the effluent quality of the electroless plating wastewater obtained in this emb...

Embodiment 2

[0037] Example 2 (production line)

[0038] The influent water quality of the electroless plating wastewater to be treated is: the pH of the wastewater is 4.5, the total nickel content is 110 mg / L, and the total phosphorus content is 883 mg / L.

[0039] Treatment process: 10 tons of post-nickel reaction tank water, add 25L×4 barrels of production line pickling solution (ferrous sulfate solution) and stir for 10 minutes, after the pH becomes about 4, add 25L×28 barrels of subsodium, and the pH becomes 7.5, stirred for 2h, and stood overnight. The next day, 1 ton of mud was discharged, and 250L of Ca(OH)2 solution (containing 2.25Kg of Ca(OH)2) was added, and the reaction was stirred for 2 hours. Then add 250L of CaCl2 / PAC solution, stir for 5 minutes, then add 250L of PAM, stir slowly and wait for precipitation, then take the supernatant for detection.

[0040] The effluent quality of the electroless plating wastewater is: the pH of the wastewater is 6, the total nickel conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com