Preparation method of electronic-grade hydrogen peroxide

A hydrogen peroxide, electronic-grade technology, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, molecular sieve compounds, etc., to meet quality requirements and super corrosion resistance Performance, the effect of enhancing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of electronic grade hydrogen peroxide, its specific scheme is as follows:

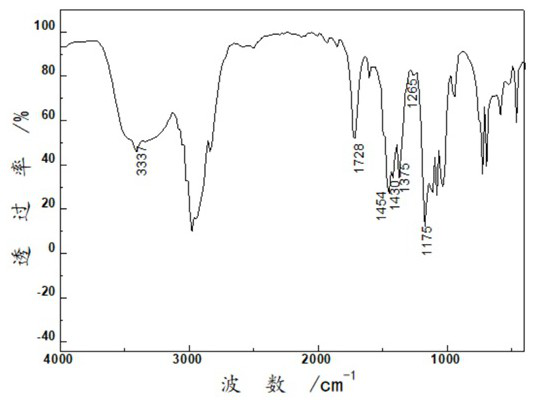

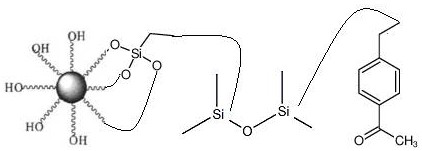

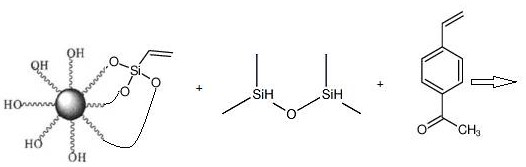

[0027] Firstly, the industrial hydrogen peroxide is precisely filtered through a nanocomposite membrane, then the organic carbon is adsorbed through an anti-oxidation mesoporous molecular sieve, and finally it is precisely filtered through a nanocomposite membrane. It is characterized in that the preparation method of the antioxidation mesoporous molecular sieve is as follows:

[0028] Mix 180kg of phenyl ketone-based mesoporous molecular sieves and 150kg of ethylene glycol phenyl ether for 1 hour, then add 0.5kg of anhydrous ferric chloride, control the temperature at 120°C, and keep warm for 5 hours. After the reaction, filter and dichloroethyl Add 150kg dichloroethane and 1.5kg cuprous chloride after washing the molecular sieve with alkane, stir and mix evenly, add 0.1kg triphenylphosphine triisosulfonic acid sodium salt, control the temperature at 65°C, stir and r...

Embodiment 2

[0036] A kind of preparation method of electronic grade hydrogen peroxide, its specific scheme is as follows:

[0037] Firstly, the industrial hydrogen peroxide is precisely filtered through a nanocomposite membrane, then the organic carbon is adsorbed through an anti-oxidation mesoporous molecular sieve, and finally it is precisely filtered through a nanocomposite membrane. It is characterized in that the preparation method of the antioxidation mesoporous molecular sieve is as follows:

[0038] Mix 220kg of phenyl ketone-based mesoporous molecular sieves and 200kg of ethylene glycol phenyl ether for 3 hours, then add 2.5kg of tin tetrachloride, control the temperature at 130°C, and keep warm for 8 hours. After the reaction, filter and dichloroethane After washing the molecular sieve, add 160kg of dichloroethane, add 1.6kg of cuprous chloride, stir and mix evenly, add 0.5kg of triphenylphosphine triisosulfonic acid sodium salt, control the temperature at 70°C, stir and react fo...

Embodiment 3

[0046] A kind of preparation method of electronic grade hydrogen peroxide, its specific scheme is as follows:

[0047] Firstly, the industrial hydrogen peroxide is precisely filtered through a nanocomposite membrane, then the organic carbon is adsorbed through an anti-oxidation mesoporous molecular sieve, and finally it is precisely filtered through a nanocomposite membrane. It is characterized in that the preparation method of the antioxidation mesoporous molecular sieve is as follows:

[0048] Mix 260kg of phenyl ketone-based mesoporous molecular sieve with 250kg of ethylene glycol phenyl ether for 5 hours, then add 5kg of anhydrous zinc chloride, control the temperature at 150°C, and keep it warm for 10 hours. After the reaction, filter and dichloroethane After washing the molecular sieve, add 180kg dichloroethane, add 2.4kg cuprous chloride, stir and mix evenly, add 0.8kg triphenylphosphine triisosulfonic acid sodium salt, control the temperature at 80°C, stir and react for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com