Polypeptide flexible liposome as well as preparation method and application thereof

A liposome and peptide flexible technology, applied in the field of personal care products, can solve the problem that active peptides are difficult to exert their efficacy, and achieve the effect of increasing transdermal performance and strong deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

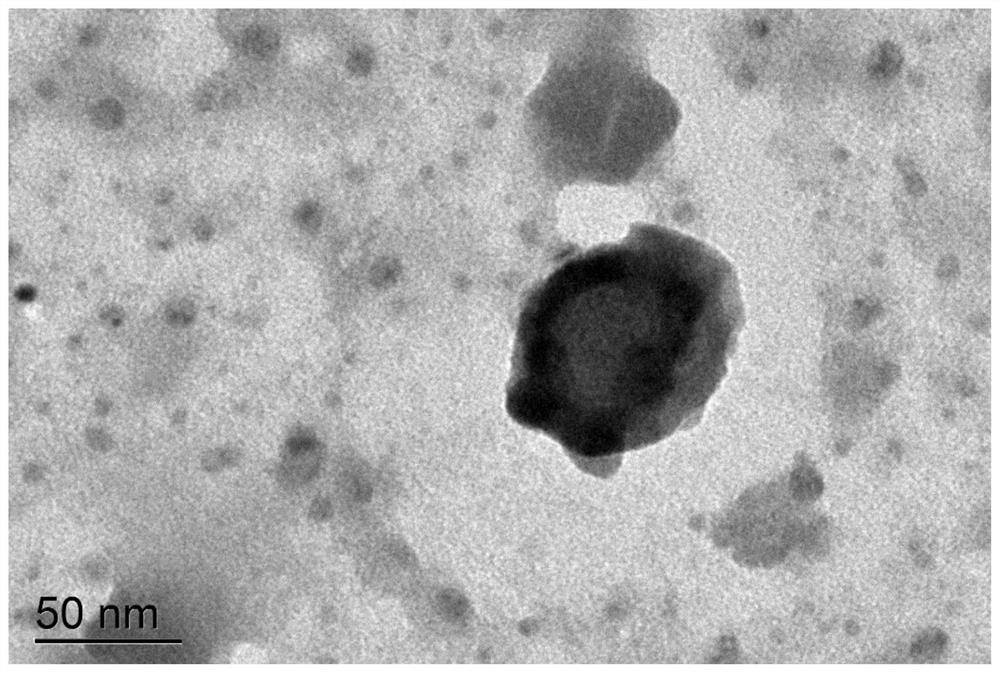

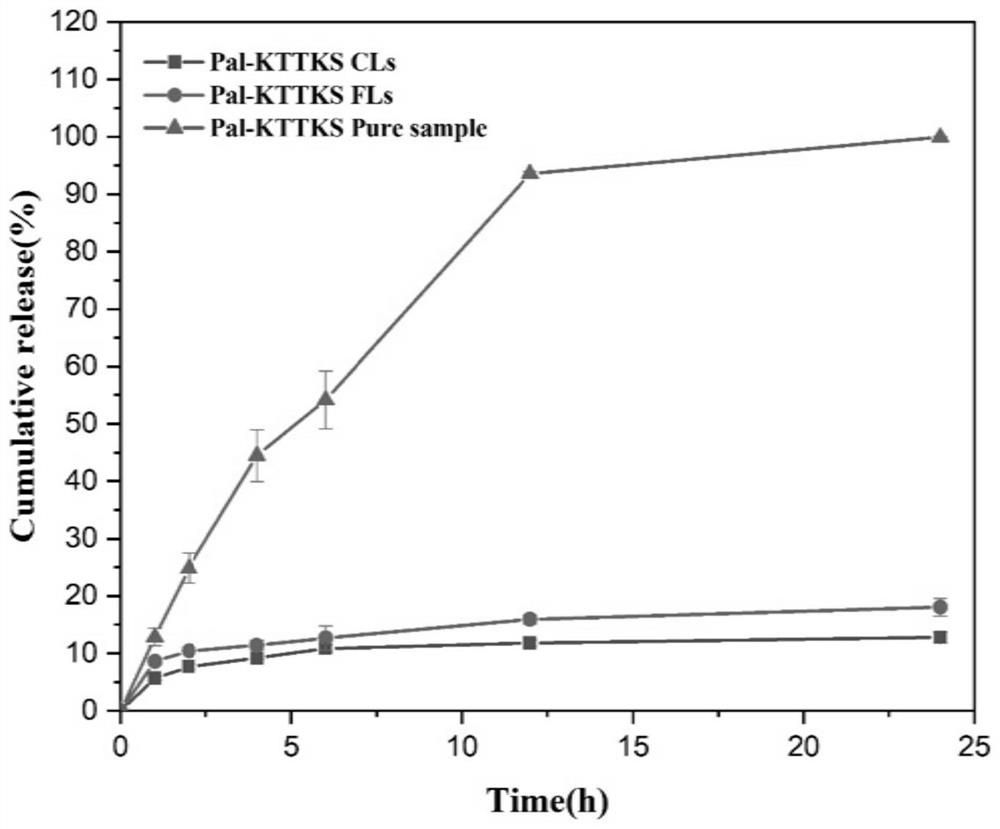

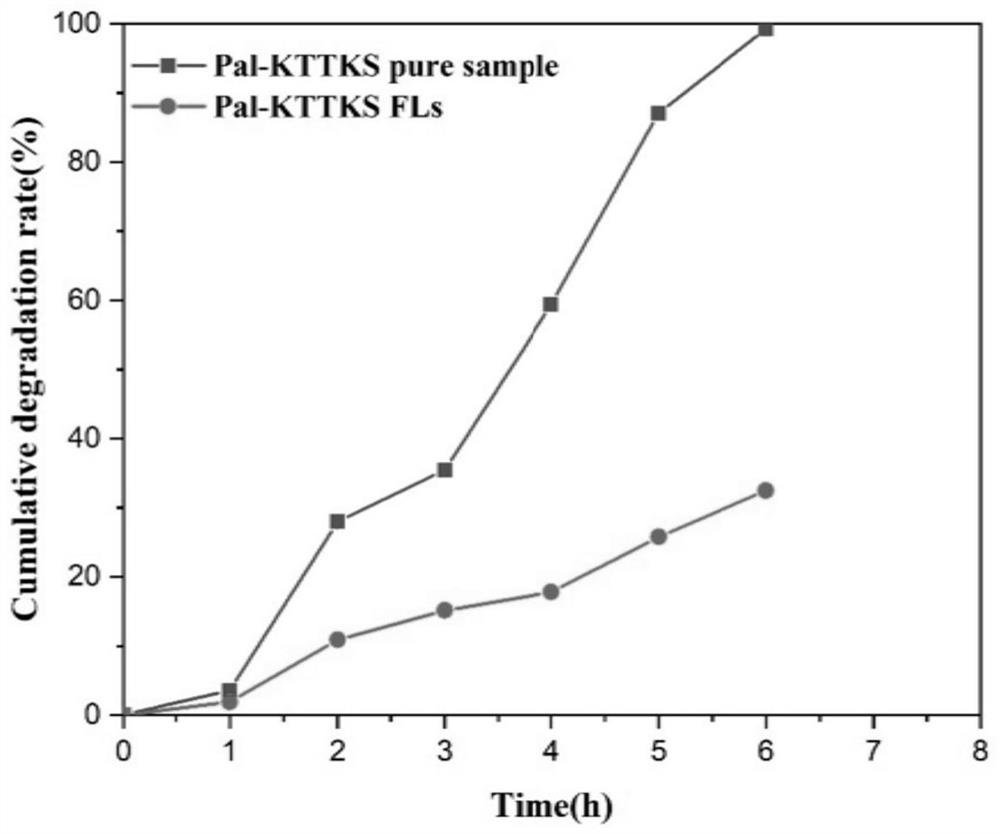

Image

Examples

Embodiment 1

[0030] Take 0.03g of palmitoyl pentapeptide-4, 0.2g of cholesterol, 3g of soybean lecithin and 0.2g of sodium cholate and place them in a rotary evaporator. Then add 10ml of methanol, ultrasonic and assisted by hand shaking to accelerate the dissolution until the solution turns into a clear and transparent yellow liquid. The organic solution was rotary evaporated at 40° C. for 1 h, and a light yellow film was left on the wall of the bottle at this time.

[0031] The rotary evaporator was placed in a vacuum drying oven, the temperature was set at 25° C., and the time was 1 h, and the trace amount of methanol in the film was removed by vacuum drying.

[0032] Take 90ml of aqueous solution, add 0.3g of Tween-20, mix the two evenly with ultrasound, then pour the solution into a rotary evaporator, stir in a water bath at 45°C for 0.5h to hydrate the film, and then sonicate until the bottle wall until the film is completely peeled off. At this point a pale yellow emulsion was obta...

Embodiment 2

[0035] Take 0.08g of palmitoyl pentapeptide-4, 0.3g of cholesterol, 5g of egg yolk lecithin and 0.3g of sodium deoxycholate and place them in a rotary evaporator. Then add 10ml of ethanol, and accelerate the dissolution with ultrasonication and hand shaking until the solution turns into a clear and transparent yellow liquid. The organic solution was rotary evaporated at 35° C. for 1.5 h, and a light yellow film was left on the bottle wall at this time.

[0036] The rotary evaporator was placed in a vacuum drying oven, the temperature was set at 30° C., the time was 0.5 h, and the remaining methanol in the film was removed by vacuum drying.

[0037] Take 95ml of aqueous solution, add 0.5g of Span-40, mix the two evenly with ultrasound, then pour the solution into a rotary evaporator, stir in a water bath at 40°C for 0.5h to hydrate the film, and then sonicate until the bottle wall until the film is completely peeled off. At this point a pale yellow emulsion was obtained.

[...

Embodiment 3

[0040] Take 0.05g of palmitoyl pentapeptide-4, 4g of phosphatidylcholine, 0.25g of cholesterol, 0.25g of sodium cholate, and dissolve them in 10ml of chloroform, sonicate and use hand shaking to accelerate the dissolution until the solution becomes clear and transparent yellow liquid. The organic solution was poured into a rotary evaporator, and the organic solution was rotary evaporated at 45° C. for 2 hours. At this time, a layer of light yellow film was left on the bottle wall.

[0041] The rotary evaporator was placed in a vacuum drying oven, the temperature was set at 35° C., and the time was 2 hours, and the residual chloroform in the film was removed by vacuum drying.

[0042] Take 90ml of aqueous solution, add 0.4g of Span-20, mix the two evenly by ultrasound, then pour the solution into a rotary evaporator, stir in a water bath at 30°C for 1 hour to hydrate the film, and then sonicate until it reaches the surface of the bottle wall until the film is completely peeled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com