Preparation method of subminiature magnetic ferroferric oxide nanoparticles

A technology of ferroferric oxide and nanoparticles, applied in the direction of iron oxide/hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of difficult control of nucleation and growth process, and achieve low raw material cost, easy control, size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 5mmol ferric chloride in 25mL deionized water in beaker A.

[0029] (2) Dissolve 15mmol sodium hydroxide in 25mL deionized water in beaker B.

[0030] (3) Add the solution in the B beaker to the A beaker under the condition of magnetic stirring, and stir for 30 minutes to obtain brown ferrihydrite precipitation.

[0031] (4) Centrifuge the ferrihydrite precipitate, wash once with deionized water and absolute ethanol, pour off the supernatant, mix well with 50mL ethylene glycol, then transfer to a 250mL three-necked round-bottomed flask, and heat to boiling , and then keep boiling and refluxing for 12 hours, stop the reaction, and cool to room temperature to obtain a reaction solution containing ultra-small magnetic iron ferric oxide nanoparticles. Ultra-small magnetic iron ferric oxide nanoparticles are obtained through solid-liquid separation.

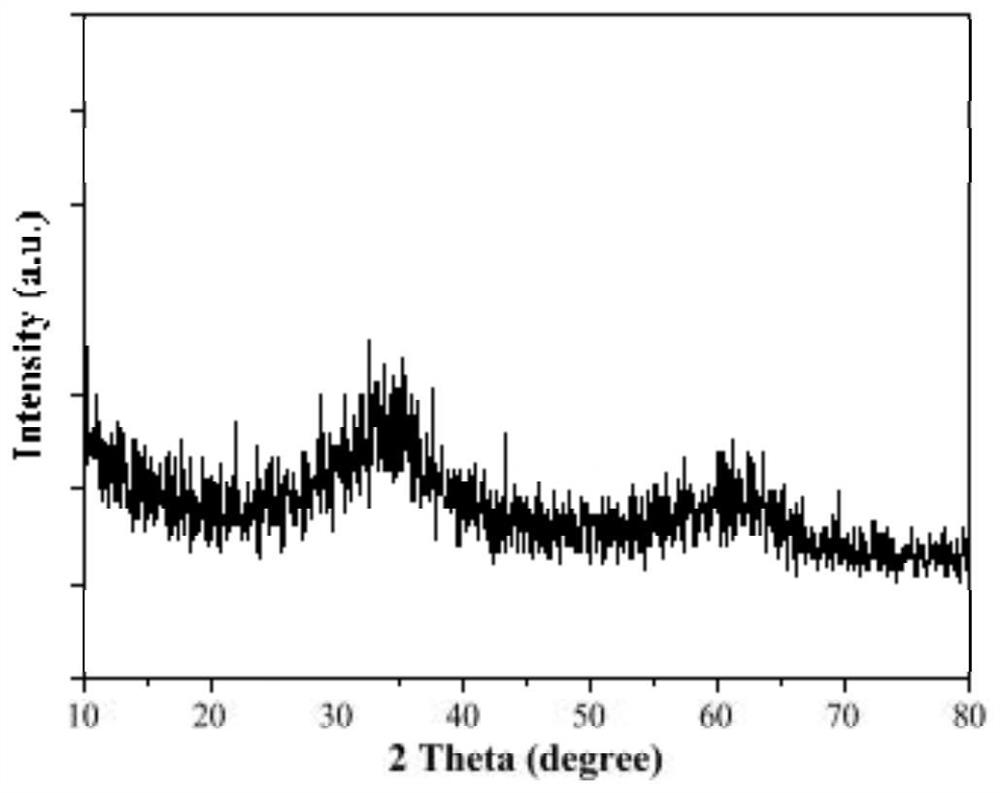

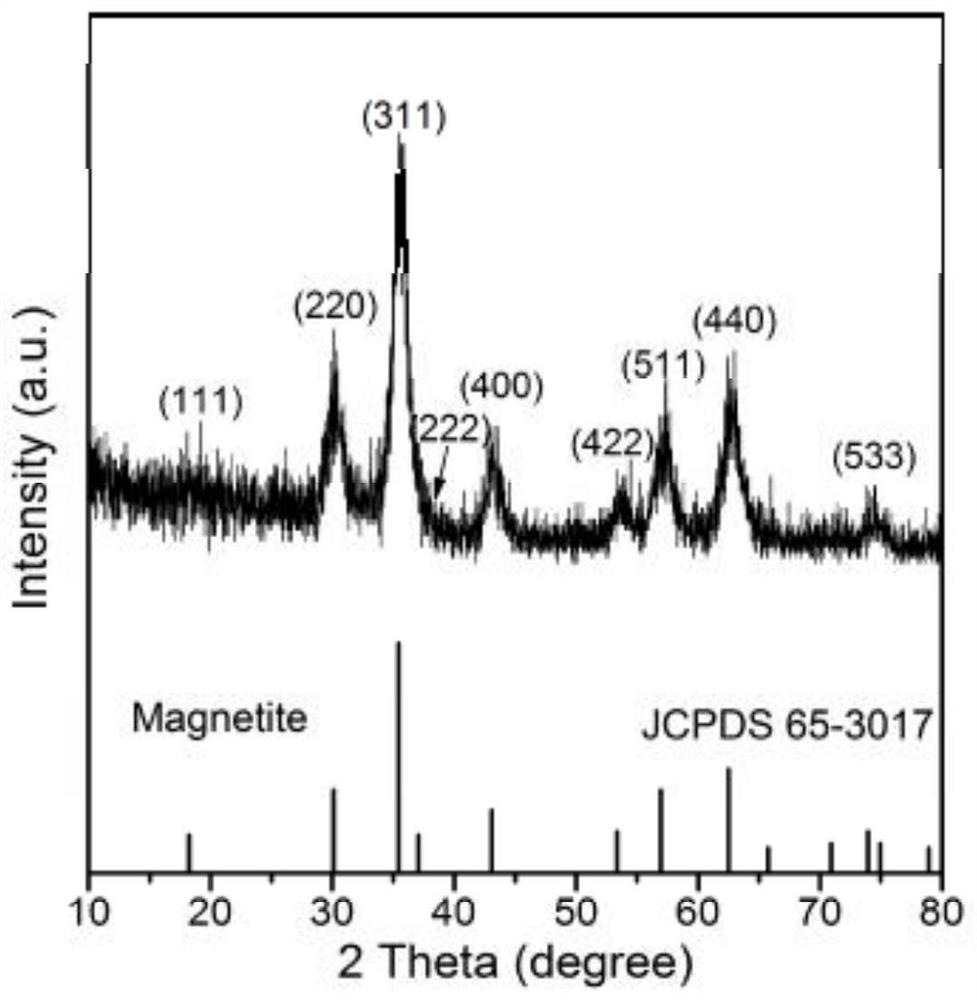

[0032] figure 1 Shown is the X-ray diffraction pattern (XRD) of ferrihydrite obtained in this embodiment, it ...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is that the boiling reflux time in the step (4) is 30 minutes. Other method steps are identical with embodiment 1.

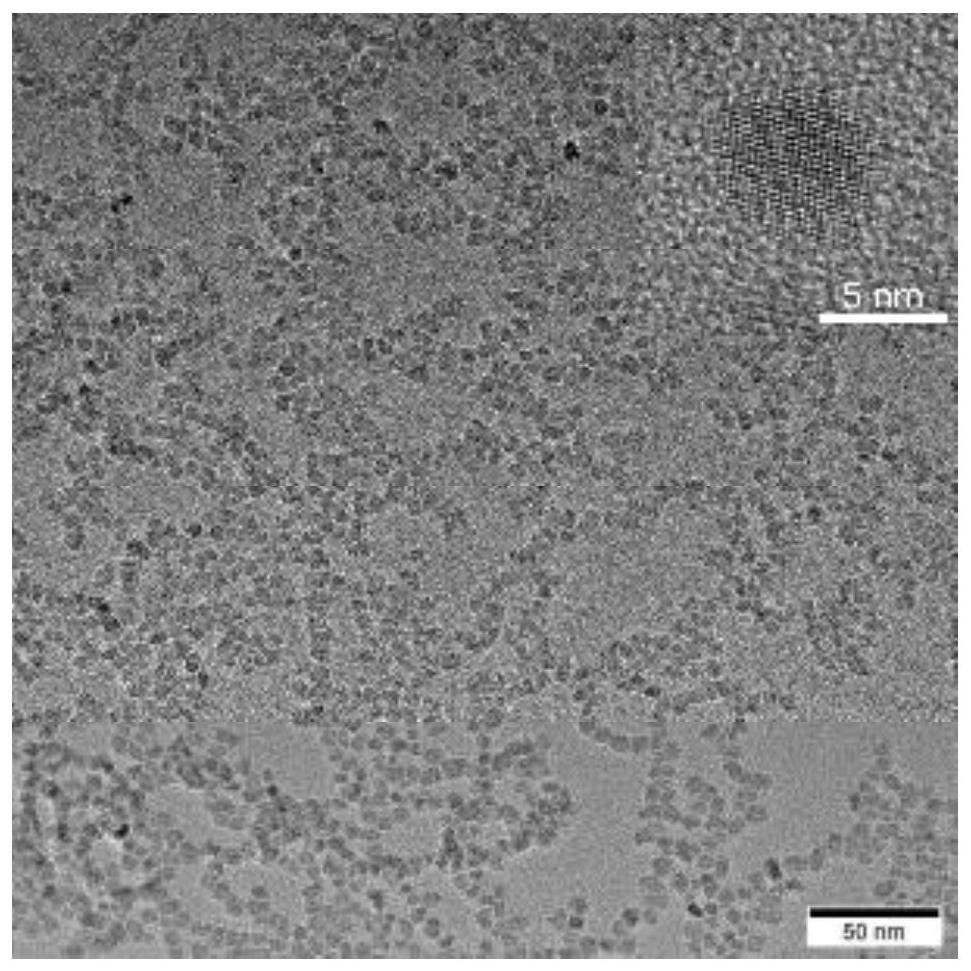

[0035] Image 6 Shown is a transmission electron microscope (TEM) image of the ultra-small magnetic iron ferric oxide nanoparticles obtained in this embodiment. It can be seen from the figure that the obtained iron ferric oxide nanoparticles are uniform in size, with an average particle diameter of about 2.5 nm.

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is that the boiling reflux time in the step (4) is 1 hour. Other method steps are identical with embodiment 1.

[0038] Figure 7Shown is a transmission electron microscope (TEM) image of the ultra-small magnetic iron ferric oxide nanoparticles obtained in this example. It can be seen from the figure that the obtained iron ferric oxide nanoparticles are uniform in size, with an average particle diameter of about 3.8 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com