Method for preparing chloromethane by utilizing chlorine-based CVD (Chemical Vapor Deposition) process tail gas generated by Si or SiC crystal film growth

A thin film growth, methyl chloride technology, applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., to achieve the effect of reducing production costs, reducing tail gas emissions, and solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

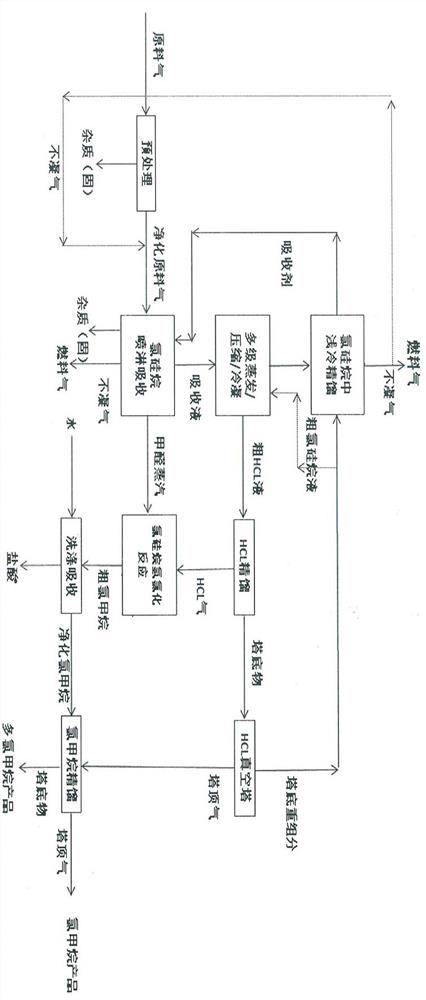

[0034] Such as figure 1 Shown, a kind of method that utilizes the chlorine-based CVD process tail gas FTrPSA of Si / SiC crystal film growth to prepare methyl chloride, concrete implementation steps comprise,

[0035] (1) Raw material gas, using chlorosilane (SiHmCln) / silane (SiH4) as the main source of silicon (Si) and hydrogen chloride (HCl) as the chlorine base for chemical vapor deposition (CVD) growth to prepare Si / silicon carbide (SiC) The tail gas of crystal or / and epitaxial film, its main composition is hydrogen (H2) and HCl, and a small amount of methane (CH4), carbon two and carbon two or more components (C2+), SiH4 / SiHmCln, trace carbon monoxide (CO) , carbon dioxide (CO2), water (H2O) and silicon dioxide (SiO2), Si / C fine particles, normal pressure and temperature.

[0036] (2) Pretreatment, the raw material gas is pressurized and sent to the pretreatment unit consisting of a dust collector, a particle filter, and an oil mist collector, and is removed successively u...

Embodiment 2

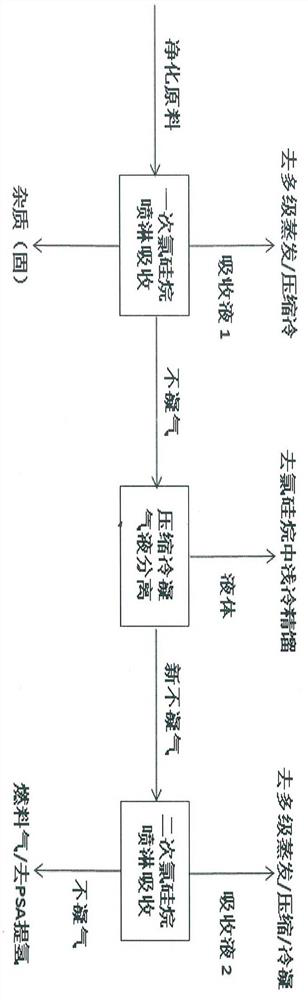

[0045] Such as figure 2As shown, on the basis of Example 1, when the concentration of HCl and chlorosilane contained in the purified raw gas is relatively high, such as greater than 5%, the chlorosilane spray absorption process needs to add a second medium-temperature chlorosilane absorption process, that is, The non-condensable gas from the chlorosilane spray absorption process is compressed, condensed, and gas-liquid separated to form a new non-condensable gas. Enter from the bottom of the absorption tower, use mixed liquid containing chlorosilane / HCl as the absorbent, spray from the top of the secondary chlorosilane spray absorption tower to perform reverse mass transfer exchange with new non-condensable gas, flow out from the bottom of the absorption tower for enrichment The absorption liquid 2 of chlorosilane and HCl is mixed with the absorption liquid 1 of the primary chlorosilane spray absorption process, and then enters the multi-stage evaporation / compression / condensa...

Embodiment 3

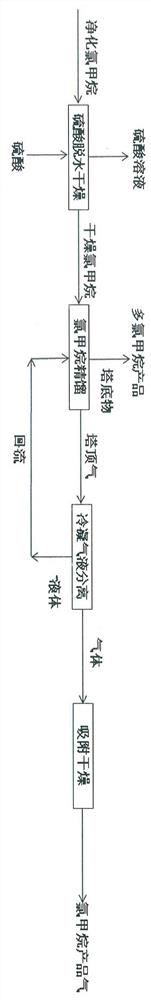

[0047] Such as image 3 Shown, on the basis of embodiment 1, under the condition that contains more polychloromethane and moisture in the purifying methyl chloride gas that comes from washing and absorbing process, such as water content is greater than 500ppm, after purifying methyl chloride gas first through sulfuric acid dehydration and drying, After being processed by the rectification process of methyl chloride, the top gas is distilled from the top of the rectification tower and separated from gas and liquid by condensation, the liquid is returned to the rectification tower as reflux, and the gas enters an adsorption drying process to obtain the methyl chloride product Gas, the purity is greater than or equal to 99.99%, and the bottom distillate of the rectification tower contains polychloromethane, which is sent to the outside of the boundary area for rectification and separation to obtain the respective products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com