Anti-warping high-modulus organic silicon insulating tape and preparation method thereof

An insulating tape, silicone pressure-sensitive adhesive technology, used in adhesives, non-polymer adhesive additives, film/sheet release coatings, etc. , slip and other problems, to achieve the effect of solving slip, high friction coefficient and low migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 7

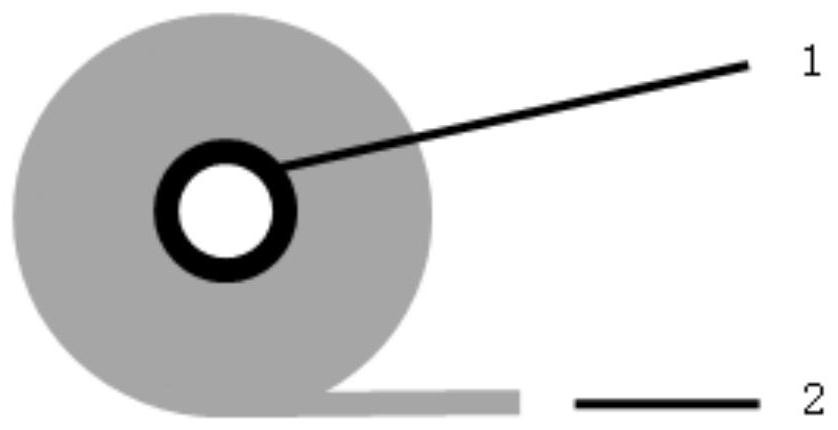

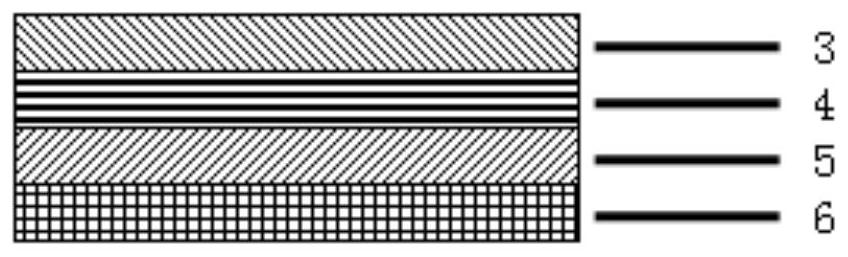

[0070]An anti-warping high-modulus silicone insulating tape, which is sequentially composed of (high temperature resistance, low migration, high friction coefficient) anti-warping resin coating, resin insulating film layer, high adhesion silicone resin layer, and high modulus Silicone pressure-sensitive adhesive layer composite composition;

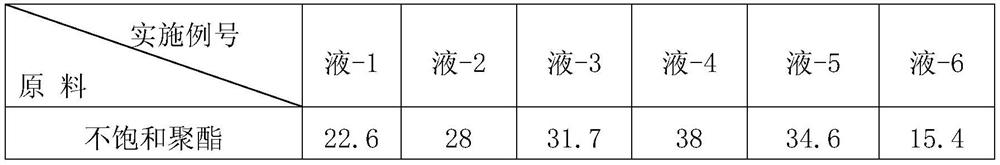

[0071] The (high temperature resistance, low migration, high friction coefficient) anti-warp resin coating is composed of anti-warp coating resin, the preparation method of the anti-warp coating resin is: at room temperature, the hydroxyl value of 140 ~ 160 20 parts by weight of unsaturated polyester, 5 parts by weight of aliphatic epoxy resin, 4 parts by weight of high-butyl etherified glycoluril resin, 15 parts by weight of butyl acetate, 5 parts by weight of 120# solvent naphtha, after mixing and stirring (get mixing material), then add (mixture weight) 400 times the weight of ethyl acetate, and dilute it into an anti-warping resin coa...

Embodiment 8

[0076] An anti-warping high-modulus silicone insulating tape, which is sequentially composed of (high temperature resistance, low migration, high friction coefficient) anti-warping resin coating, resin insulating film layer, high adhesion silicone resin layer, and high modulus Silicone pressure-sensitive adhesive layer composite composition;

[0077] The (high temperature resistance, low migration, high friction coefficient) anti-warp resin coating is composed of anti-warp coating resin, the preparation method of the anti-warp coating resin is: at room temperature, the hydroxyl value of 140 ~ 160 40 parts by weight of unsaturated polyester, 10 parts by weight of aliphatic epoxy resin, 8 parts by weight of high-butyl etherified glycoluril resin, 30 parts by weight of butyl acetate, 15 parts by weight of 120# solvent naphtha, after mixing and stirring (get mixing material), then add (the weight of the mixture) 1300 times the weight of ethyl acetate, and dilute it into an anti-wa...

Embodiment 9

[0082] An anti-warping high-modulus silicone insulating tape, which is sequentially composed of (high temperature resistance, low migration, high friction coefficient) anti-warping resin coating, resin insulating film layer, high adhesion silicone resin layer, and high modulus Silicone pressure-sensitive adhesive layer composite composition;

[0083] The (high temperature resistance, low migration, high friction coefficient) anti-warp resin coating is composed of anti-warp coating resin, the preparation method of the anti-warp coating resin is: at room temperature, the hydroxyl value of 140 ~ 160 30 parts by weight of unsaturated polyester, 8 parts by weight of aliphatic epoxy resin, 6 parts by weight of high-butyl etherified glycoluril resin, 23 parts by weight of butyl acetate, 10 parts by weight of 120# solvent naphtha, after mixing and stirring (get mixing material), then add (mixture weight) 850 times the weight of ethyl acetate, and dilute it into an anti-warping resin c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com