Preparation method of recombinant bacillus subtilis and glutathione

A technology of Bacillus subtilis and glutathione, which is applied in the field of bioengineering, can solve the problems of low yield and unsuitability for mass production, and achieve the effects of high yield, high yield, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Construction of Recombinant Bacillus subtilis Engineering Bacteria for GSH Production

[0058] The bifunctional glutathione synthase gene (SEQ ID NO: 1) derived from Streptococcus thermophilus (gshFst) was selected, and the gene fragment of the bifunctional glutathione synthase was amplified using the recombinant plasmid pET28a-gshFst as a template, The linearized plasmid was obtained by double digestion with BamHI and SmaI, and the recombinant plasmid pHT-ST was obtained by ligation under the action of T4 ligase.

[0059] Preparation of DNA fragments: The recombinant plasmid pET28a-gshFst already in the laboratory was used as a template for DNA amplification. The reaction conditions were: pre-denaturation at 98°C for 5 min; denaturation at 98°C for 10 s; annealing at 60°C for 30 s; extension at 72°C for 5 min, a total of 30 cycles; after the end, final extension at 72°C for 10 min. The amplified product was verified by nucleic acid electrophoresis and purified by PCR ...

Embodiment 2

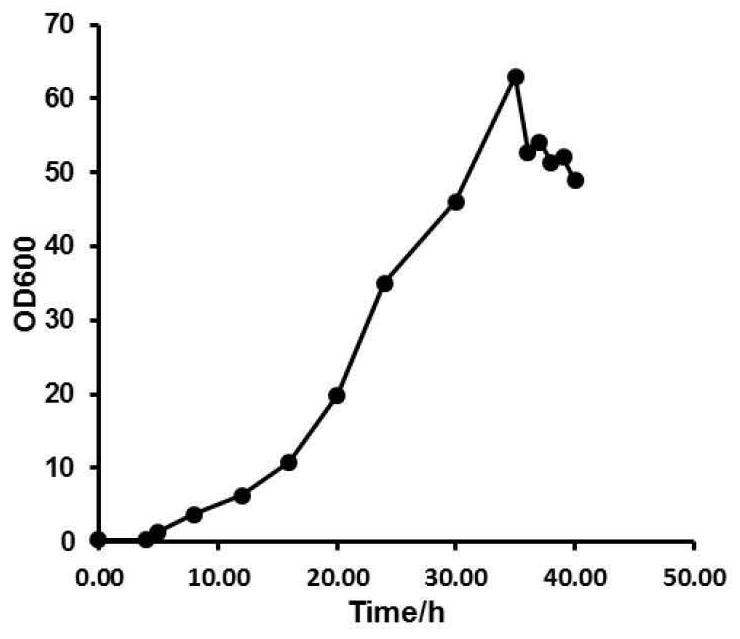

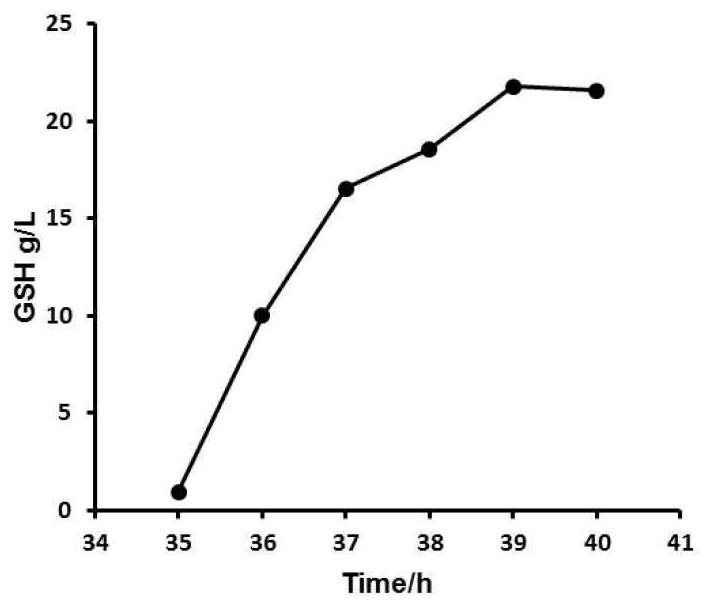

[0063] Production of GSH by Recombinant Bacteria BS-ST

[0064] (1) Inoculate the recombinant BS-ST engineered strains stored in glycerol tubes into LB medium, and culture them at 30°C for 11 hours as primary seeds.

[0065] (2) Transfer the primary seeds into LB liquid medium, and culture at 30° C. for 13 hours to obtain the secondary seed culture solution.

[0066] (3) Secondary seed culture liquid is inoculated in the fermentor tank of 2L by 10% inoculum size and carries out fed-batch fermentation, and fermentation medium adopts corn flour 10g / L, glucose 2g / L, industrial peptone 5g / L, Corn steep liquor 3g / L, urea 1g / L, calcium carbonate 0.5g / L, magnesium sulfate 0.8g / L, potassium dihydrogen phosphate 0.5g / L, dipotassium hydrogen phosphate 0.5g / L, feed solution containing glucose 500g / L L, peptone 2g / L, culture temperature 37°C, culture pH 6.8, fermentation 30h, OD600 is 46 at this time, add 1mM inducer IPTG to the medium, continue to culture for 5h, finally add glutamic ac...

Embodiment 3

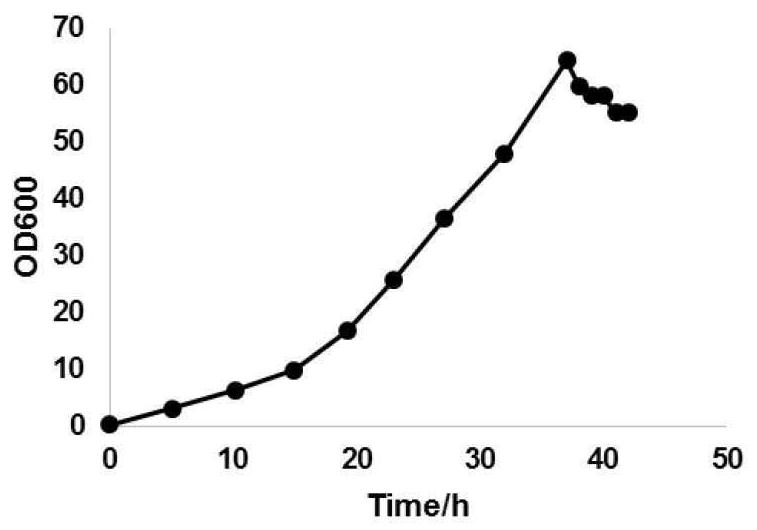

[0069] Production of GSH by Recombinant Bacteria BS-ST

[0070] (1) Inoculate the recombinant BS-ST engineered strains stored in glycerol tubes into LB medium, and cultivate them at 30°C for 12 hours as primary seeds.

[0071] (2) The primary seeds were transferred into LB liquid medium, and cultured at 30° C. for 10 h to obtain the secondary seed culture solution.

[0072] (3) Secondary seed culture liquid is inoculated into the fermentor of 2L by 9.5% inoculum size and carries out fed-batch fermentation, and fermentation medium adopts corn flour 5g / L, glucose 3g / L, industrial peptone 4g / L, Corn steep liquor 3g / L, urea 0.5g / L, calcium carbonate 1.5g / L, magnesium sulfate 1.5g / L, potassium dihydrogen phosphate 0.4g / L, dipotassium hydrogen phosphate 0.4g / L, feeding solution containing 500g of glucose / L, peptone 1g / L, culture temperature 37°C, culture pH 6.8, fermentation 32h, OD600 is 48 at this time, add 1mM inducer IPTG to the medium, continue to culture for 5h, finally add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com