Application of metal organic framework material as catalyst in preparation of plasticizer

A metal-organic framework and organic framework technology, which is applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve problems such as increased processing costs, many side reactions, and product catalyst residues , to achieve the effects of reducing transportation and storage costs, facilitating transportation and storage, and high catalytic yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

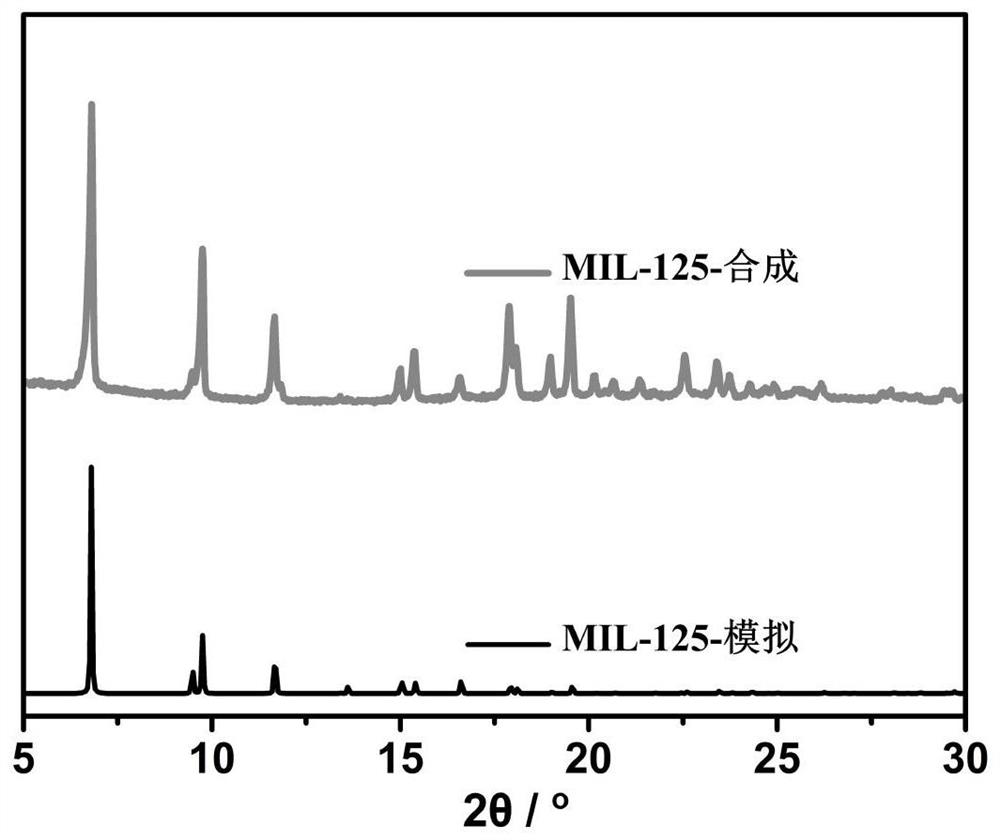

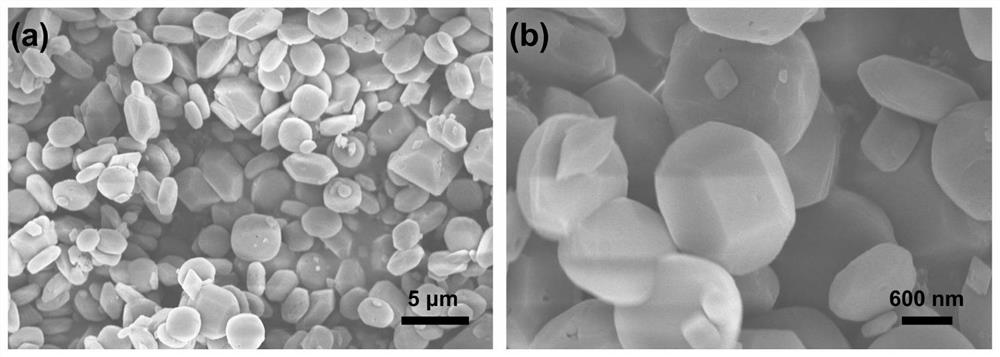

Method used

Image

Examples

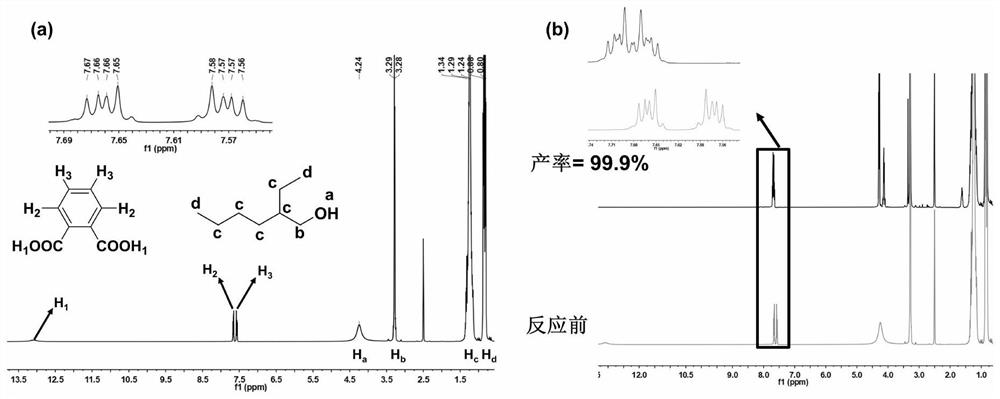

Embodiment 1

[0039] According to the mole fraction ratio of phthalic acid, butanol and catalyst is 1:4:0.01, respectively add phthalic acid, butanol and MIL-125 into a 50mL round bottom flask, and add a magnetic stirrer with a diameter of 5mm Fix the round bottom flask on the iron stand. Pour simethicone oil with a viscosity of 100cps into a 150mm crystallization dish, place the crystallization dish on a heating magnetic stirrer, set the heating temperature to 100 degrees Celsius, and set the stirring speed to 300r / min. When the temperature in the crystallization dish reaches the set temperature, immerse the round-bottom flask fixed on the iron stand in simethicone oil, stir and react for 5 hours, then remove the round-bottom flask from the crystallization dish, and stop the heating reaction. Take 100 μL of the mixture from the mixed system and add it to the NMR tube, and then add 0.5 mL deuterated dimethyl sulfoxide (Dimethyl Sulfoxide-d 6 , DMSO) to carry out nuclear magnetic detection ...

Embodiment 2

[0041] According to the mole fraction ratio of phthalic acid, amyl alcohol and catalyst as 1:6:0.01, respectively add phthalic acid, amyl alcohol and MIL-125 into a 50mL round bottom flask, and add a magnetic stirrer with a diameter of 5mm Fix the round bottom flask on the iron stand. Pour simethicone oil with a viscosity of 100cps into a 150mm crystallization dish, place the crystallization dish on a heating magnetic stirrer, set the heating temperature to 150 degrees Celsius, and set the stirring speed to 300r / min. When the temperature in the crystallization dish reaches the set temperature, immerse the round-bottom flask fixed on the iron stand in simethicone oil, stir and react for 3 hours, then remove the round-bottom flask from the crystallization dish, and stop the heating reaction. Take 100 μL of the mixture from the mixed system and add it to the NMR tube, and then add 0.5 mL deuterated dimethyl sulfoxide (Dimethyl Sulfoxide-d 6 , DMSO) for nuclear magnetic detection...

Embodiment 3

[0043] According to the mole fraction ratio of phthalic acid, isooctyl alcohol and catalyst as 1:10:0.01, respectively add phthalic acid, alcohol and MIL-125 into a 50mL round bottom flask, and add a magnetic stirrer with a diameter of 5mm Fix the round bottom flask on the iron stand. Pour simethicone oil with a viscosity of 100cps into a 150mm crystallization dish, place the crystallization dish on a heating magnetic stirrer, set the heating temperature to 190 degrees Celsius, and set the stirring speed to 300r / min. When the temperature in the crystallization dish reaches the set temperature, immerse the round-bottom flask fixed on the iron stand in simethicone oil, stir and react for 1 hour, then remove the round-bottom flask from the crystallization dish, and stop the heating reaction. Take 100 μL of the mixture from the mixed system and add it to the NMR tube, and then add 0.5 mL deuterated dimethyl sulfoxide (Dimethyl Sulfoxide-d 6 , DMSO) for nuclear magnetic detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com