Metal resin composite binding agent diamond grinding wheel for PCB micro-drill grooving and preparation method of metal resin composite binding agent diamond grinding wheel

A composite bond and diamond grinding wheel technology, which is applied in the field of diamond grinding wheels, can solve the problems of late start, low precision of machine tool equipment, long research and development cycle, etc., and achieve high feed speed, good chip capacity and thermal conductivity, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

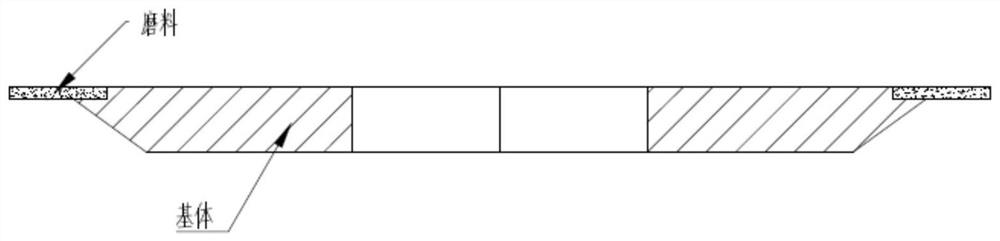

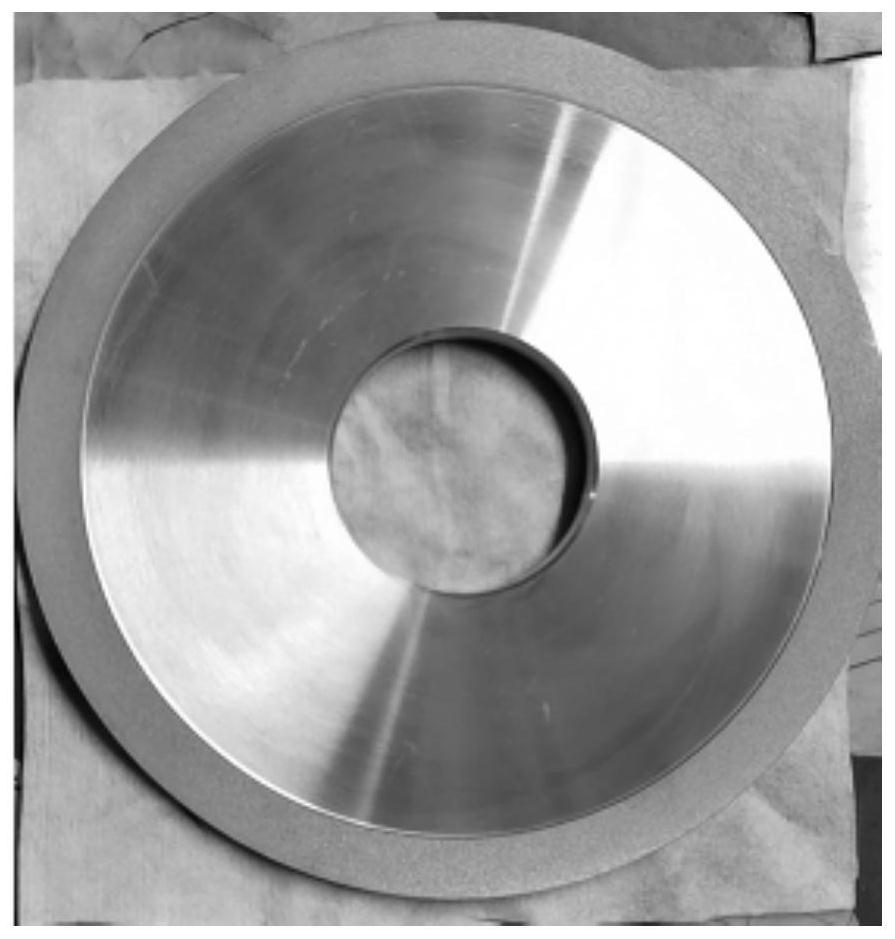

[0031] Embodiment one prepares metal-resin composite bond diamond grinding wheel, comprises the following steps:

[0032] (1) Put 60 / 40 copper-tin alloy powder with 60% volume percentage and 40% modified polyimide resin powder in a three-dimensional mixer for 4 hours, then pass through a 400-mesh standard sieve to obtain a composite Binding agent;

[0033] (2) Put the composite binder and diamond micropowder in a beaker, add acetone to submerge the powder, use a magnetic stirrer for conventional mixing for 1 h, pass through a 400-mesh standard sieve after natural drying, then add ammonium bicarbonate, and mix well Pass through a 400-mesh standard sieve again to obtain the grinding layer mixture;

[0034] Among them, the volume percentages of diamond abrasives, composite binders, and ammonium bicarbonate are: 35%, 45%, and 20%;

[0035] (3) Put the grinding layer mixture into the existing mold, scrape it flat, place it in an environment with a vacuum degree of 0.08 Pa and a p...

Embodiment 2

[0041] To prepare metal-resin composite bond diamond grinding wheel, adjust the volume percentage of 60 / 40 copper-tin alloy powder and modified polyimide resin powder to 50% 60 / 40 copper-tin alloy powder, 50% modified polyimide resin powder; adjust the volume percentages of diamond abrasive, composite binder, and ammonium bicarbonate in step (2) of Example 1 to: 30%, 55%, and 15%. All the rest were prepared according to the preparation method of Example 1 to obtain a composite bond diamond grinding wheel for slotting PCB micro-drills.

[0042] This grinding wheel is actually used in PCB micro-drilling (0.5mm diameter) tool slotting (0.12mm), the feed speed is 1400 mm / min; the dressing gap is 70,000 pieces of dressing, the service life is 75% higher than the resin grinding wheel, and the comprehensive processing efficiency is increased by 150. %.

Embodiment 3

[0044] Prepare metal-resin composite bond diamond grinding wheel, adjust the volume percentage of 60 / 40 copper-tin alloy powder and modified polyimide resin powder to 40% 60 / 40 copper-tin alloy powder, 60% modified polyimide resin powder; the volume percentages of diamond abrasives, composite binders, and ammonium bicarbonate in step (2) of Example 1 are adjusted to: 25%, 65%, and 10%; the rest are implemented according to The preparation method of example 1 obtains the composite bond diamond grinding wheel for slotting PCB micro-drilling.

[0045] This grinding wheel is actually used in PCB micro-drilling (0.5mm diameter) tool slotting (0.12mm), the feed speed is 1500 mm / min; the dressing gap is 60,000 pieces of dressing; the service life is 50% higher than that of resin grinding wheels; the comprehensive processing efficiency is increased by 100 %.

[0046] As can be seen from the above, compared with the existing PCB micro-drilling and slotting grinding wheel, the grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com