Flexible copper-clad plate substrate, preparation method and application thereof, and circuit board

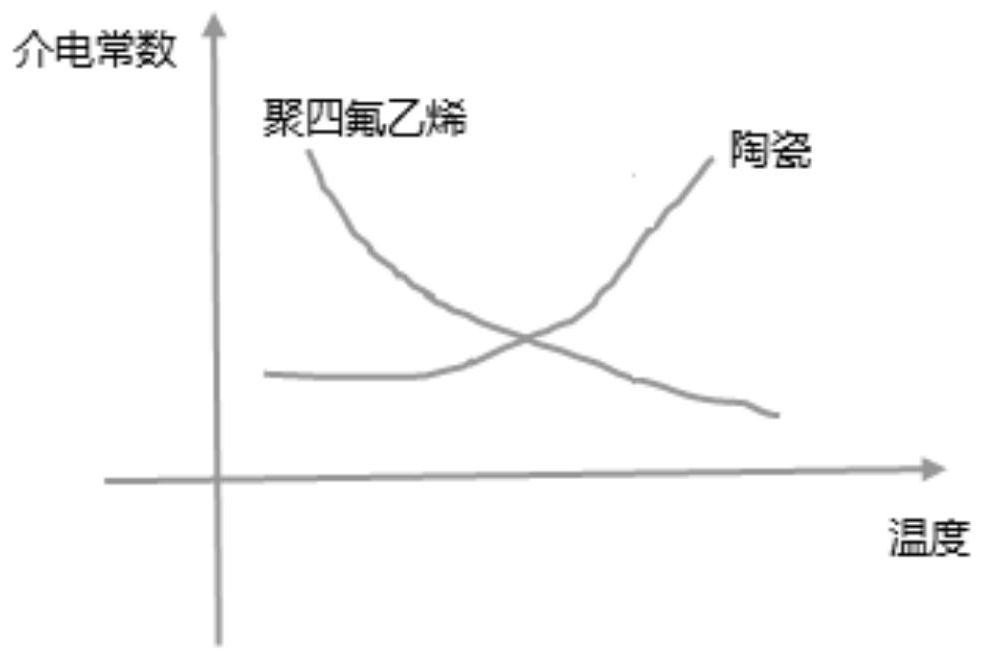

A flexible copper clad laminate and substrate technology, applied in circuit substrate materials, printed circuit components, etc., can solve the problems of poor electrical performance of flexible copper clad laminate substrates, and achieve good dielectric constant consistency, simple operation, Low dielectric loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] In addition, the present application also provides a method for preparing the above-mentioned flexible copper-clad laminate base material, which may include the following steps: sintering the mixture of ceramic material and polytetrafluoroethylene material. When the raw materials for the preparation of the flexible copper clad laminate base material also include additives, the mixture of the ceramic material, the polytetrafluoroethylene material and the additives is sintered.

[0082] In an optional embodiment, when the raw materials for the preparation of the flexible copper-clad laminate base material include additives, the mixture is obtained in the following manner: firstly mixing the ceramic material with the additives, and then mixing with the polytetrafluoroethylene material. By first mixing the ceramic material and the auxiliary agent, the auxiliary agent modifies the surface of the ceramic material and reduces its surface energy activity.

[0083] In an optiona...

Embodiment 1

[0096] The calcium titanate, strontium titanate and barium titanate are respectively modified with rare earth elements, the rare earth elements are lanthanum and yttrium, and the total amount of lanthanum and yttrium used for each ceramic material to be modified is 0.5 wt% of material. The silicon dioxide, titanium dioxide, modified strontium titanate, modified calcium titanate, modified barium titanate, aluminum oxide and zinc oxide whiskers were respectively ball milled to a particle size of 0.8 μm.

[0097] Using chemical mixing and dispersing, and using additives to carry out the second surface modification of the above ceramic materials. The auxiliary agent is composed of coupling agent, surfactant and oxidizing agent in a mass ratio of 1:1:1. The dosage of the additive is 0.5wt‰ of the ceramic material, and the ceramic material is 40wt% of the preparation raw material.

[0098] The silicon dioxide, titanium dioxide, strontium titanate, calcium titanate, barium titanate...

Embodiment 2

[0106] The calcium titanate, strontium titanate, and barium titanate are respectively modified with rare earth elements, the rare earth elements are lanthanum, cerium, erbium and yttrium, and the total amount of rare earth elements used for each ceramic material to be modified is 0.1wt% of the modified ceramic material. Silicon dioxide, titanium dioxide, modified strontium titanate, modified calcium titanate, modified barium titanate, aluminum oxide and zinc oxide whiskers were respectively ball milled to a particle size of 1.5 μm.

[0107] Chemical mixing and dispersion are used to modify the surface of the above-mentioned ceramic materials with additives. The additives are composed of coupling agent, surfactant and oxidizing agent in a mass ratio of 1:1:1. The dosage of the auxiliary agent is 1wt‰ of the ceramic material, and the ceramic material is 70wt% of the raw material for preparation.

[0108] Take the silicon dioxide, titanium dioxide, strontium titanate, calcium ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com