Organic silicon foam with in-situ demulsification and adsorption function and application of organic silicon foam in oil-water separation

A silicone foam and demulsification technology, applied in the direction of adsorption water/sewage treatment, liquid separation, separation methods, etc., can solve the problems of high treatment cost, single lipophilic and hydrophobic function, unsuitable for steady-state oil pollution control, etc., to achieve Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

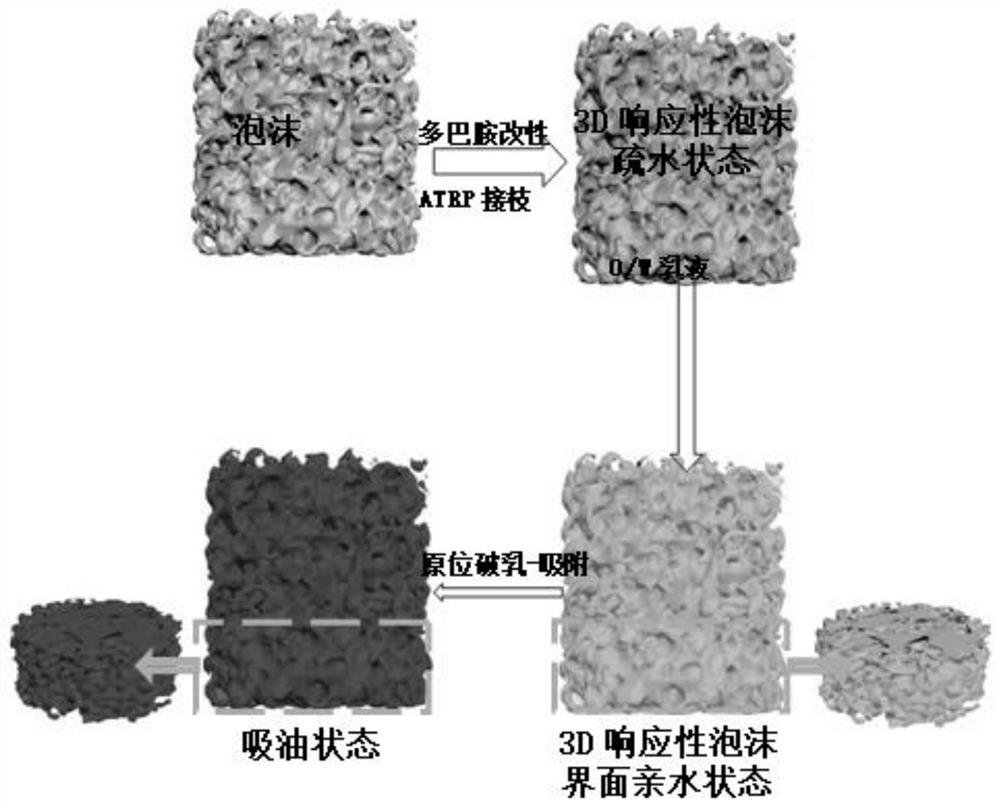

[0031] Such as figure 1 As shown, 1g of melamine foam was impregnated in 1×10 -3 mol / L, pH value of 10 dopamine aqueous solution, soak for 4 hours, take out, wash and dry; soak the foam in 1% 2-bromoisobutyryl bromide solution for graft modification for 4 hours, take out and wash drying; 100g tetrahydrofuran, 10g CH 2 =CH-CO-O-(EO) 10 -(CH 2 ) 4 CH 3 , and 1g catalyst (CuBr / Me 6 TREN, CuBr and Me 6 The molar ratio of TREN is 1:1) and mix evenly, add the foam impregnated with 2-bromoisobutyryl bromide dichloromethane solution, N 2 React at 60°C for 5h under atmosphere, add 25g CH 2 =CH-CO-O-(CH 2 ) 3 -[SiO(CH 3 ) 2 ] 29 Si(CH 3 ) 3, continue to react for 5h, and obtain silicone foam with in-situ demulsification and adsorption function.

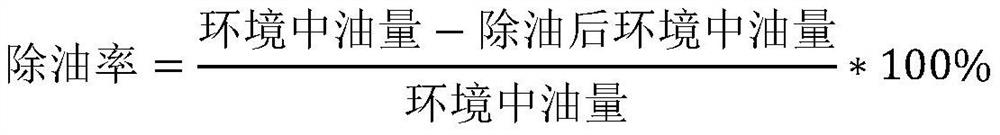

[0032] 12h foam oil removal rate: cationic 88.3%, anionic 88.2%, non-ionic 87.4%.

[0033] 24h foam oil removal rate: cationic 99.5%, anionic 99.8%, non-ionic 97%.

Embodiment 2

[0045] Immerse 10g foam melamine in 5×10 -3 mol / L, pH value of 7.5 dopamine solution, soak for 48 hours, take out, wash and dry; soak the foam in 1% 2-bromoisobutyryl bromide solution for graft modification for 20 hours, take out and wash drying; 200g dichloromethane, 100g CH 2 =CH-CO-O-(EO) 20 (CH 2 ) 7 CH 3 , and 5g catalyst (CuBr / Me 6 TREN, CuBr and Me 6 The molar ratio of TREN is 1:1) and mix evenly, add the foam impregnated with 2-bromoisobutyryl bromide dichloromethane solution, N 2 Under atmosphere, react at 60°C for 10h, add 90g CH 2 =CH-CO-O-(CH 2 ) 3 -[SiO(CH 3 ) 2 ] 99 Si(CH 3 ) 3 , continue to react for 10h, and obtain silicone foam with in-situ demulsification and adsorption function.

[0046] 12h foam oil removal rate: cationic 89.3%, anionic 86.5%, non-ionic 88.3%.

[0047] 12h foam oil removal rate: cationic 98.5%, anionic 97.8%, non-ionic 96.5%.

Embodiment 3

[0049] Dip 5g of polyurethane foam into 1×10 -1 mol / L, pH value of 9 dopamine solution, soak for 40 hours, take out, wash and dry; soak the foam in 2-bromoisobutyryl bromide solution with a mass fraction of 20% for graft modification for 4 hours, take out and wash drying; 200g toluene, 100g CH 2 =CCH 3 -CO-O-(EO) 20 , and 4g catalyst (CuBr / Me 6 TREN, CuBr and Me 6 The molar ratio of TREN is 1:1) and mix evenly, add the foam impregnated with 2-bromoisobutyryl bromide dichloromethane solution, N 2 React at 100°C for 5h under atmosphere, add 40g CH 2 =CH-CO-O-(CH 2 ) 3 -[SiO(CH 3 ) 2 ] 29 Si(CH 3 ) 3 , continue to react for 10h, and obtain silicone foam with in-situ demulsification and adsorption function.

[0050] 12h foam oil removal rate: cationic 55.5%, anionic 53.8%, non-ionic 50.7%.

[0051] 24h foam oil removal rate: cationic 78.5%, anionic 74.6%, non-ionic 71.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil removal rate | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com