Animal hair-like polyester filament cosmetic brush hair and production process thereof

A production process and wool polyester technology, applied in the direction of single-component polyester rayon, bristles, chemical post-treatment of synthetic polymer rayon, etc., can solve the problem of bacteria breeding, skin allergy, low antibacterial performance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

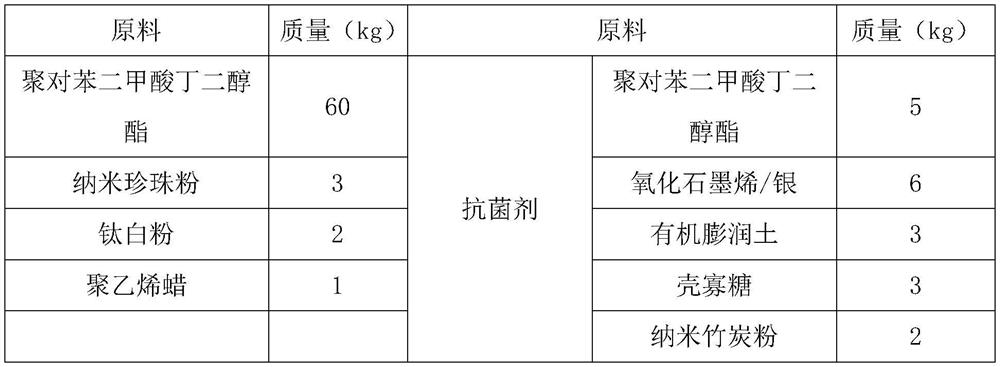

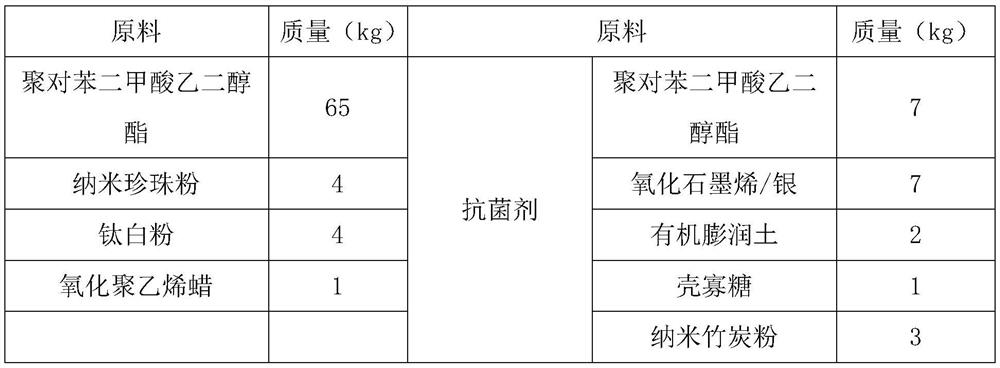

Method used

Image

Examples

preparation example 1

[0042] The preparation method of graphene oxide / silver composite is:

[0043] (1) Add 10kg graphene oxide and 1000L deionized water into the stirring tank, then ultrasonically promote the dispersion of graphene oxide, add ammonia water to the deionized water, adjust the pH to 9.2, add 3kg ethylenediamine, and Stir at a speed of min for 10 minutes, pass nitrogen into the stirring tank for 30 minutes, the nitrogen flow rate is 2L / min, remove the oxygen in the reaction vessel, and then continue stirring at 80°C for 40 minutes;

[0044] (2) After the reaction, the material in the stirring tank was vacuum filtered, and washed 3 times with an ethanol solution with a mass fraction of 50%, then the filter cake was placed in a vacuum drying oven, dried at 80°C for 24h, and ground and dried The filter cake is passed through a 100-mesh sieve to obtain reduced graphene oxide;

[0045] (3) Reduced graphene oxide is dispersed in 1000L DMF, after the dispersion is uniform, add 8kg of sodium l...

preparation example 2

[0049] (1) Add 10kg graphene oxide and 1000L deionized water into the stirring tank, then ultrasonically promote the dispersion of graphene oxide, add ammonia water to the deionized water, adjust the pH to 10.1, add 2.5kg ethylenediamine, and Stir for 15 minutes at a speed of 1 / min, feed nitrogen into the stirring tank for 30 minutes, the nitrogen flow rate is 2L / min, remove the oxygen in the reaction vessel, and then continue stirring for 30 minutes at 100°C;

[0050] (2) After the reaction, the material in the stirring tank was vacuum filtered, and washed 4 times with an ethanol solution with a mass fraction of 50%, then the filter cake was placed in a vacuum drying oven, dried at 60°C for 24h, and ground and dried The filter cake is passed through a 100-mesh sieve to obtain reduced graphene oxide;

[0051] (3) Reduced graphene oxide is dispersed in 1000L DMF, after the dispersion is uniform, add 10kg of sodium lauryl sulfate and mix evenly, then add 2.4kg of silver nitrate,...

preparation example 3

[0055] (1) Add 10kg graphene oxide and 1000L deionized water into the stirring tank, then ultrasonically promote the dispersion of graphene oxide, add ammonia water to the deionized water, adjust the pH to 10.8, add 3kg ethylenediamine, and Stir at a speed of min for 15 minutes, pass nitrogen into the stirring tank for 30 minutes, the nitrogen flow rate is 2L / min, remove the oxygen in the reaction vessel, and then continue stirring at 120°C for 20 minutes;

[0056] (2) After the reaction, the material in the stirring tank was vacuum filtered, and washed 5 times with an ethanol solution with a mass fraction of 50%, then the filter cake was placed in a vacuum drying oven, dried at 60°C for 24h, and ground and dried The filter cake is passed through a 100-mesh sieve to obtain reduced graphene oxide;

[0057] (3) Reduced graphene oxide is dispersed in 1000L DMF, after the dispersion is uniform, add 10kg of sodium lauryl sulfate and mix evenly, then add 3kg of silver nitrate, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com