Ion imprinted material for rapid color development and detection of copper ions and preparation method and application thereof

An ion imprinting and copper ion technology, which is applied in the direction of chemical reaction of materials for analysis, material analysis by observing the impact on chemical indicators, and improvement of process efficiency, which can solve problems such as low sensitivity and coexisting ion interference. , to achieve the effect of strong anti-interference ability, low detection conditions and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Diphenylsemicarbazide and CuCl 2 Dissolve in ethanol solution at a molar ratio of 2:1, sonicate until completely dissolved, stir for pre-polymerization at room temperature for 3 hours, and prepare solution 1;

[0028] (2) Add 20mmol ethylene glycol dimethacrylate (EGDMA) and 0.05g azobisisobutyronitrile (AIBN) to the toluene solution, fully dissolve and mix it as solution 2;

[0029] (3) Mix the solution 1 obtained in step (1) with the solution 2 obtained in step (2), then add 35 mL of hydroxyethyl cellulose (HEC) solution, pass through nitrogen for 15 minutes to remove oxygen, and shake and polymerize at 70 ° C for 6 hours, to obtain polymerized products;

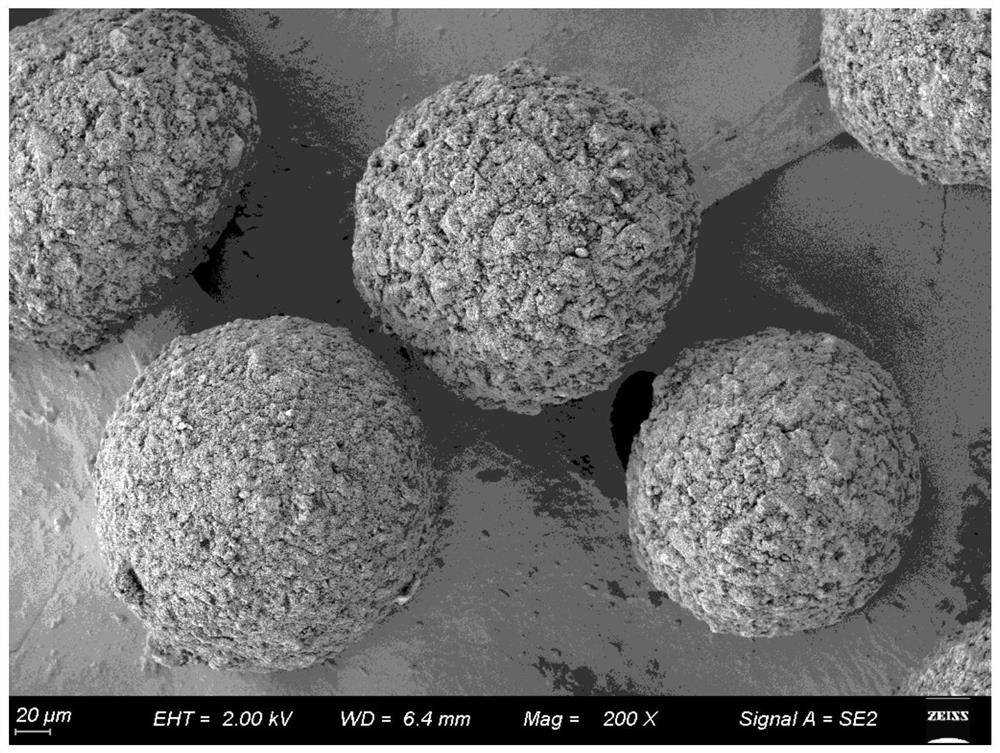

[0030] (4) washing the polymer product obtained in step (3) with methanol until clarification, to wash away unreacted functional monomers and cross-linking agents; then eluting with HCl solution to remove template copper ions until it cannot be detected by flame atomic absorption spectrometer then washed with ...

Embodiment 2

[0032] The copper ion rapid color development detection ion imprint material (material hereinafter referred to as material) obtained in embodiment 1 is carried out each performance index measurement:

[0033] Add 10mg of material to 50mL for a concentration of 100mg L -1 In different pH values of copper ion solutions, shake at 25°C for 120 minutes to measure the adsorption effect of materials on copper ions at different pH values. The results show that when the pH value is 5, the adsorption capacity of the material to copper ions can reach 23.54 mg g -1 , and the color effect of the material tends to be stable at this pH value. Therefore, subsequent adsorption experiments will be carried out at this pH value.

[0034] Add 10mg of material to 50mL, pH 5, concentration 100mg L -1 In the copper ion solution, the adsorption performance was measured at different adsorption times (5-300min), and the temperature was controlled at 25°C. The results showed that the adsorption rea...

Embodiment 3

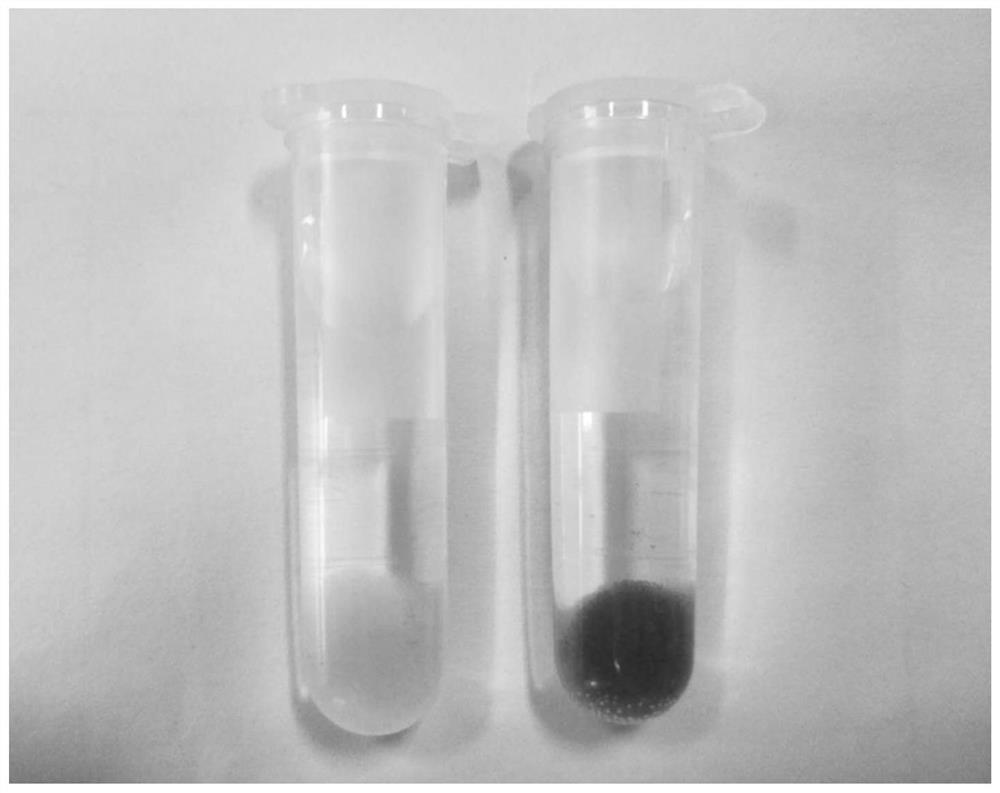

[0043] The rapid chromogenic detection of copper ion imprinted material was used for the on-site detection of copper ion in environmental water samples. Collect river water, lake water, pond water and well water samples. The pH value of each water sample is within 6-7, and there is no need to adjust the pH. Take 10mg of the material and add it to 5mL of water sample, shake it for 30s and let it stand until the material settles, the total time required is about 1 minute. The material is compared with the standard color scale of copper ions to obtain the corresponding concentration, and the result is compared with the measurement results of the atomic absorption spectrometer, as shown in Table 1 below. It can be seen that the color detection results are basically consistent with the instrument measurement results, and the accuracy is high. And in multiple parallel experiments, it can maintain stable color detection results with good reproducibility.

[0044] Table 1 The detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com