Polyvinyl alcohol graft copolymer and application thereof

A technology of graft copolymer and polyvinyl alcohol, which is applied in the field of polyvinyl alcohol graft copolymer, can solve problems such as decreased adhesion, easy powder removal, and influence on battery electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

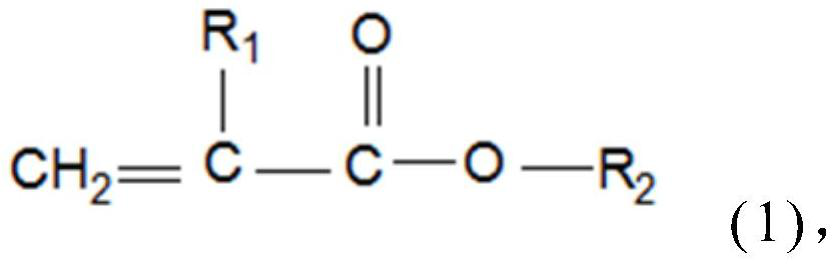

[0043] According to a preferred embodiment of the present invention, the fluorine-containing ethylenically unsaturated monomer (component (a)) has the chemical formula of formula (1):

[0044]

[0045] Among them, R 1 and R 2 At least one of them is a group substituted by a fluorine atom, and R 1 and R 2 has the following definitions:

[0046] R 1 for H, C 1 -C 4 Alkyl, or C substituted by one or more fluorine atoms 1 -C 4 alkyl; and

[0047] R 2 for H, C 1 -C 12 Alkyl, C substituted by one or more fluorine atoms 1 -C 12 Alkyl, aryl, aryl substituted with one or more fluorine atoms, aralkyl, or aralkyl substituted with one or more fluorine atoms.

[0048] According to some embodiments of the present invention, R 1 Preferably H, C 1 -C 3 Alkyl, or C substituted by one or more fluorine atoms 1 -C 3 Alkyl, more preferably H, methyl or trifluoromethyl.

[0049] According to some embodiments of the present invention, R 2 Preferably H, C 1 -C 8 Alkyl, C sub...

preparation example 1 to 5

[0104] Preparation Examples 1 to 5: Polyvinyl alcohol (hereinafter referred to as "PVA") GOHSENOL GL-05 (Nippon Synthetic Chemicals) was dissolved in 7200 ml of water, and stirred thoroughly to obtain a uniform, transparent and viscous polyvinyl alcohol aqueous solution. The oxygen in the aqueous solution was excluded by continuing to blow nitrogen gas for about 60 minutes. Then 2,2,2-trifluoroethyl (meth)acrylate (Sigma-Aldrich; 99% purity), (meth)acrylic acid (Sigma-Aldrich; 99% purity), (meth)acrylamide (Sigma -Aldrich; purity 98%), hexyl (meth)acrylate (Sigma-Aldrich; purity 99%) and 1% sodium persulfate aqueous solution, stir and mix evenly, heat up to 70°C and continue to react for 4 hours, thereby preparing polyethylene Alcohol graft copolymer (hereinafter referred to as "graft PVA"), which is used as the water-based binder of Preparation Examples 1 to 5 (solid content is 5.2% by weight). The amount of reactant used for each grafted PVA is recorded in Table 1.

preparation example 6 and 7

[0105] Preparation Examples 6 and 7: (meth)acrylamide was replaced by N-methylolacrylamide (Merck; purity 48%) as an ethylenically unsaturated amide monomer, and the rest of the preparation steps were as in Preparation Examples 1 to 5 above. The amounts of reactants are listed in Table 1. The resulting product had a solids content of 5.2% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com