Water-based electromagnetic shielding coating material and preparation method thereof

A technology of electromagnetic shielding and coating materials, which is applied in the direction of conductive coatings and coatings, and can solve the problems of conductive filler dispersion interface interaction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention discloses a water-based electromagnetic shielding coating material and a preparation method thereof whose mechanical properties are enhanced by adjusting pH, the steps are as follows:

[0035](1) Utilizing the self-polymerization reaction of dopamine hydrochloride to modify the nano-carbon material to prepare polydopamine-modified nano-carbon material;

[0036] (2) Then the polydopamine-modified nano-carbon material prepared in step (1) is dispersed in water to prepare a dispersion of a certain concentration, and a small amount of dispersion is blended with an aqueous anionic polyacrylate emulsion to obtain a mixed solution. The pH value of the resulting mixed solution, observe and record the pH value M at which the complex system appears to be agglomerated;

[0037] (3) Adjust the pH value of the aqueous anionic polyacrylate emulsion and the polydopamine-modified nano-carbon material dispersion with a strong acid solution or a strong alkali solution, unti...

Embodiment 1

[0042] Preparation of water-based electromagnetic shielding coating material with enhanced mechanical properties by adjusting pH:

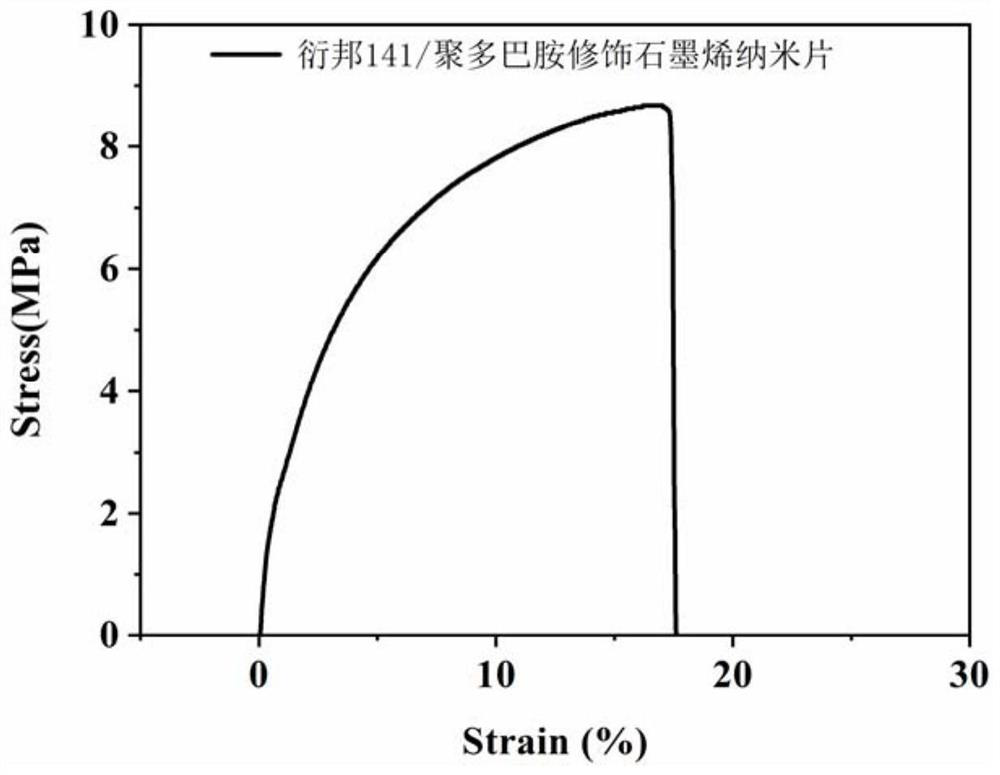

[0043] (1) Add 0.25g dopamine hydrochloride in 150mL Tris buffer and 50mL ethanol at room temperature, utilize its self-polymerization reaction to modify 0.5g graphene nanosheets under weakly alkaline conditions (pH value=8.5), react After 24 hours, filter with suction and rinse with water to prepare polydopamine-modified graphene nanosheets. Then the polydopamine-modified graphene nanosheets were dispersed in 30g water by high-speed shearing to make a dispersion with a concentration of 25mg / g, the shear rate was 5000rpm, and the time was 10 minutes;

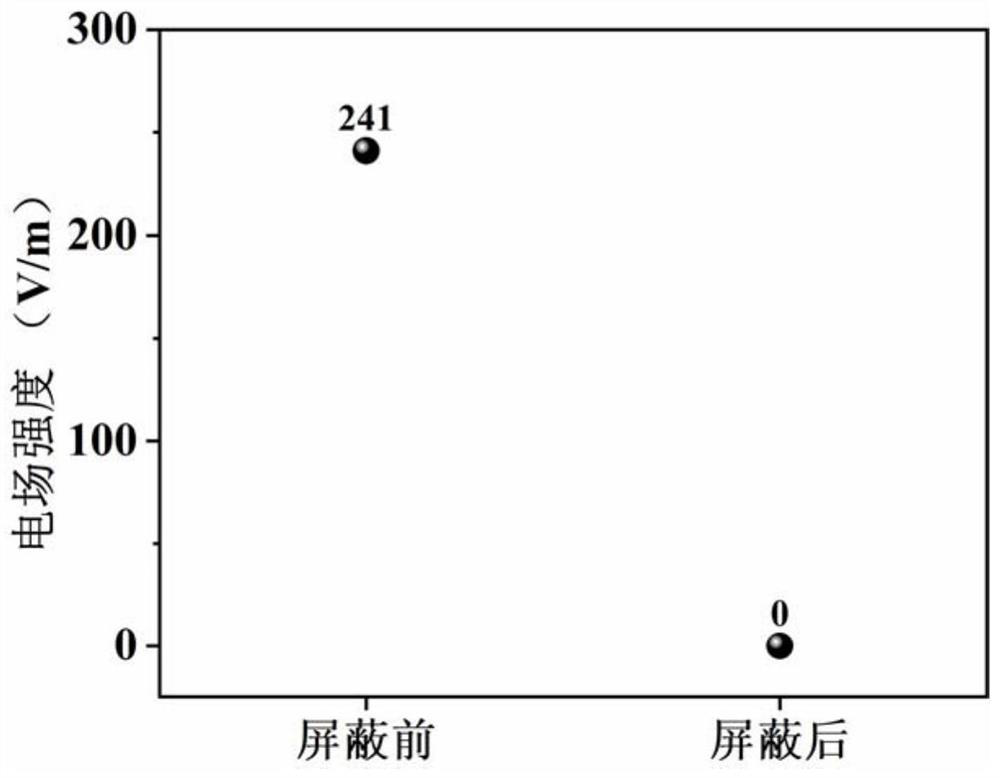

[0044] (2) Get the aqueous dispersion of 1g polydopamine-modified graphene nanosheets and 5g anionic polyacrylate emulsion Yanbang 141 to blend under magnetic stirring, and adjust the pH value with dilute sulfuric acid and sodium hydroxide solution to obtain the composite system reunited The pH is ...

Embodiment 2

[0050] Preparation of water-based electromagnetic shielding coating material with enhanced mechanical properties by adjusting pH:

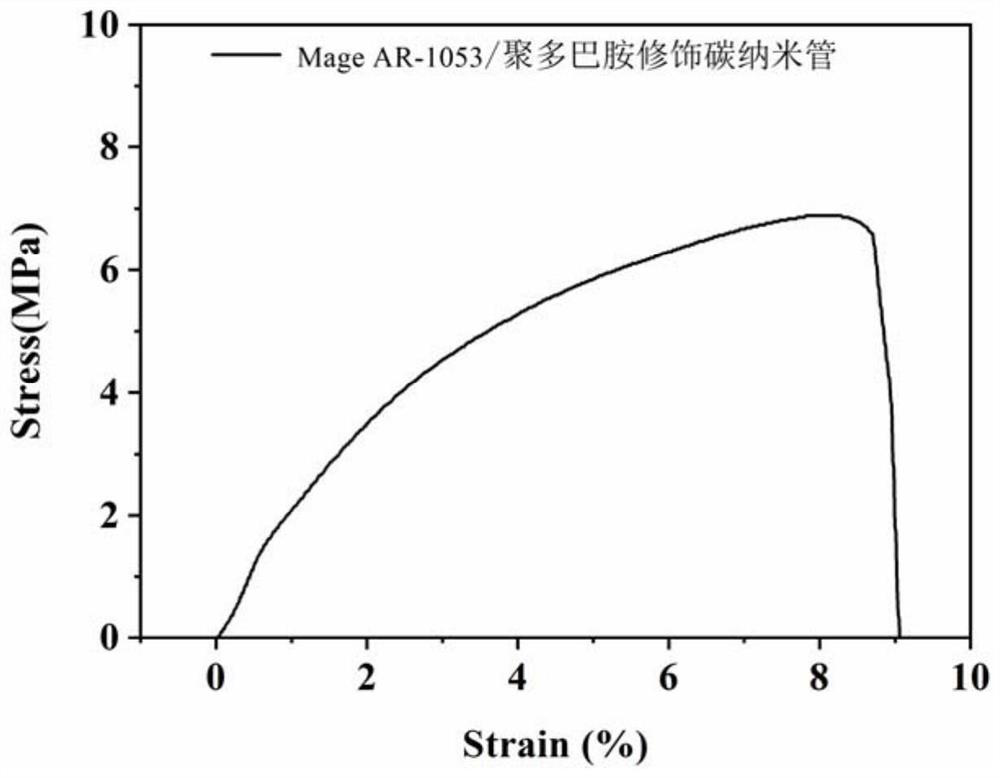

[0051] (1) Add 0.5 g of dopamine hydrochloride to 300 mL of Tris buffer and 100 mL of ethanol at room temperature, and use its self-polymerization reaction to modify 2.5 g of carbon nanotubes under weakly alkaline conditions (pH value = 8.5). Reaction 24 After one hour, filter with suction and rinse with water to prepare polydopamine-modified carbon nanotubes. Then polydopamine-modified carbon nanotubes were dispersed in 197g of water by high-speed shearing to make a dispersion with a concentration of 15mg / g, the shear rate was 5000rpm, and the time was 10 minutes;

[0052] (2) Take 1g of the water dispersion of polydopamine-modified carbon nanotubes and 5g of anionic polyacrylate emulsion Mage AR-1053 to blend under magnetic stirring, and adjust the pH value with dilute sulfuric acid and sodium hydroxide solution to obtain a composite system aggl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Electric field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com