Preparation method of cistanche enzymolysis oligosaccharide concentrated solution as well as obtained product and application

A Cistanche enzyme and technology of Cistanche, applied in the direction of cosmetic preparations, dressing preparations, skin care preparations, etc., can solve the problems of unpublished Cistanche oligosaccharide mixtures, research reports that have no efficacy of Cistanche oligosaccharide mixtures, etc., and achieve reduction Effects of skin cell damage, reduction of free radical formation, and inhibition of melanin formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

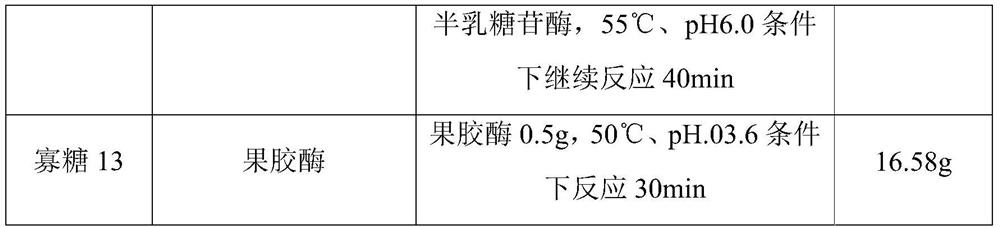

[0050] The extraction of embodiment 1 cistanche bulb polysaccharide

[0051] Fresh Cistanche bulbs are taken, sliced, dried at 40°C until the water content is <4wt%, and then pulverized, passed through a 30-mesh sieve to collect Cistanche bulb powder. Weigh 1000g of cistanche bulb powder, add purified water to make up the volume according to the solid-to-liquid ratio of 1:5, and make a solution. At 40°C, 400W ultrasonic was used to treat the solution for 40min, and the lignified structure of Cistanche deserticola powder was preliminarily destroyed. Add 1 g of cellulase, 0.4 g of hemicellulase and 1 ml of laccase to the sonicated Cistanche powder solution, and treat at 45° C. for 40 min. The enzyme-treated solution was heated to 80°C for 1 hour, and the obtained water extract was filtered, and the filter residue was extracted once with purified water at a solid-to-liquid ratio of 1:5, and the obtained water extract was filtered. The two water extracts were combined, and 10L o...

Embodiment 2

[0052] The preparation of embodiment 2 cistanche enzymolysis oligosaccharide concentrate

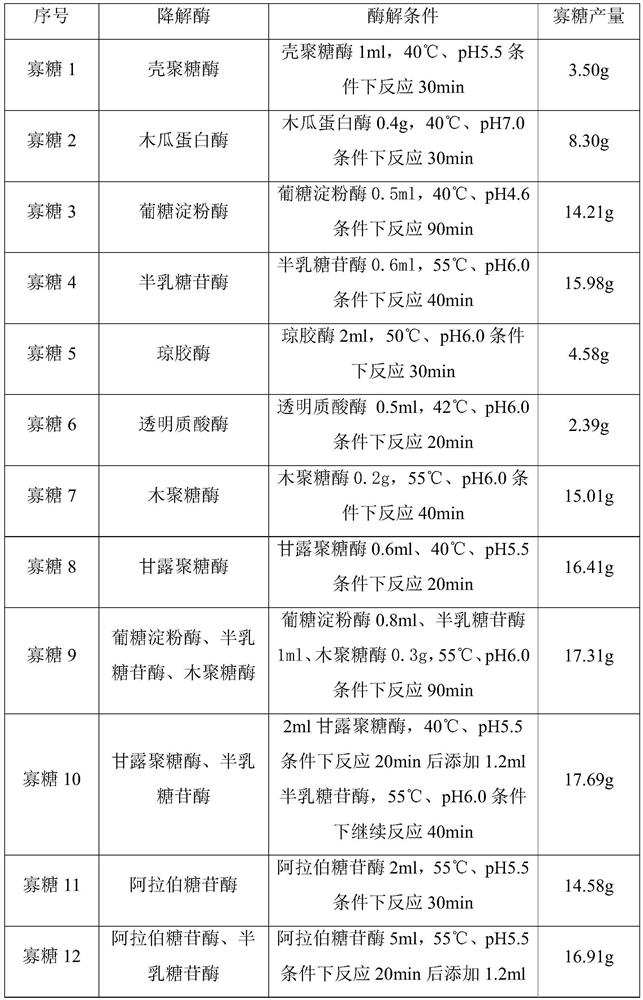

[0053] Take 20 g of cistanche bulb polysaccharide prepared in Example 1, make a solution according to a solid-to-liquid ratio of 1:5, add different degrading enzymes to the solution, and perform enzymolysis at the appropriate temperature, pH and dosage of each degrading enzyme Treatment, the enzymolysis solution obtained after enzymolysis was inactivated at 70°C for 40min, then 1wt% activated carbon was added to the enzymolysis solution, decolorized at 55°C for 40min, the decolorized enzymolysis solution was centrifuged, and the supernatant was taken. The solution is then passed through a 0.22 micron membrane filter to remove insoluble impurities. Then, the enzymolysis solution was dialyzed overnight with a dialysis bag with a molecular weight cut-off of 5000 Da to further remove polysaccharides with too high molecular weight, and the permeate was collected to obtain an enzymatic oligosa...

Embodiment 3

[0061] Fresh Cistanche bulbs are taken, sliced, dried at 40°C until the water content is <4wt%, and then pulverized, passed through a 10-mesh sieve to collect Cistanche bulb powder. Weigh an appropriate amount of cistanche bulb powder, add purified water to constant volume, and prepare a 5L solution according to the set solid-to-liquid ratio. The solution was ultrasonically treated to initially destroy the lignified structure of Cistanche powder. After ultrasonic treatment, enzyme treatment can be carried out, and then the solution after ultrasonic or enzyme treatment is subjected to water extraction, the obtained water extract is filtered, and 93% industrial ethanol, which is 5 times the volume of the water extract, is slowly added to it under stirring. , standing and settling, the supernatant is brown-black, the precipitate is black, and the texture is fine. Pour off the supernatant, add 93% industrial ethanol to the precipitate and wash it three times to obtain a loose bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com