Method for preparing CrN coating on surface of intaglio printing plate based on GIS and HIPIMS technologies

A printing plate technology, which is applied in the field of CrN coating preparation on the surface of gravure printing plate, can solve the problems of serious pollution in the electroplating process, rough coating surface, poor bonding force of the film base, etc., and achieve good brightness and compactness of the film layer , Small grains on the surface, strong film-base binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing a CrN coating on the surface of a gravure printing plate based on GIS and HIPIMS technology, characterized in that the specific steps are as follows: using a nickel plate as a base, cleaning and drying the surface of the nickel plate, and then fixing it on the turntable of a coating machine, After the coating machine is evacuated, a certain temperature and bias voltage are set, a certain amount of argon and hydrogen gas is introduced, and the gas ion source etching and cleaning technology (Gas Ion Source Etching, GISETCH) is used to make the Ar atoms and H atoms The Ar ions and H ions are ionized under the lower pressure, and the Ar ions and H ions bombard and activate the nickel plate under the action of the bias voltage to complete the etching and cleaning of the surface of the nickel plate, and then complete the preparation of the Cr+CrN composite coating under the coating process.

[0018] As a preferred technical solution of the present invent...

Embodiment 1

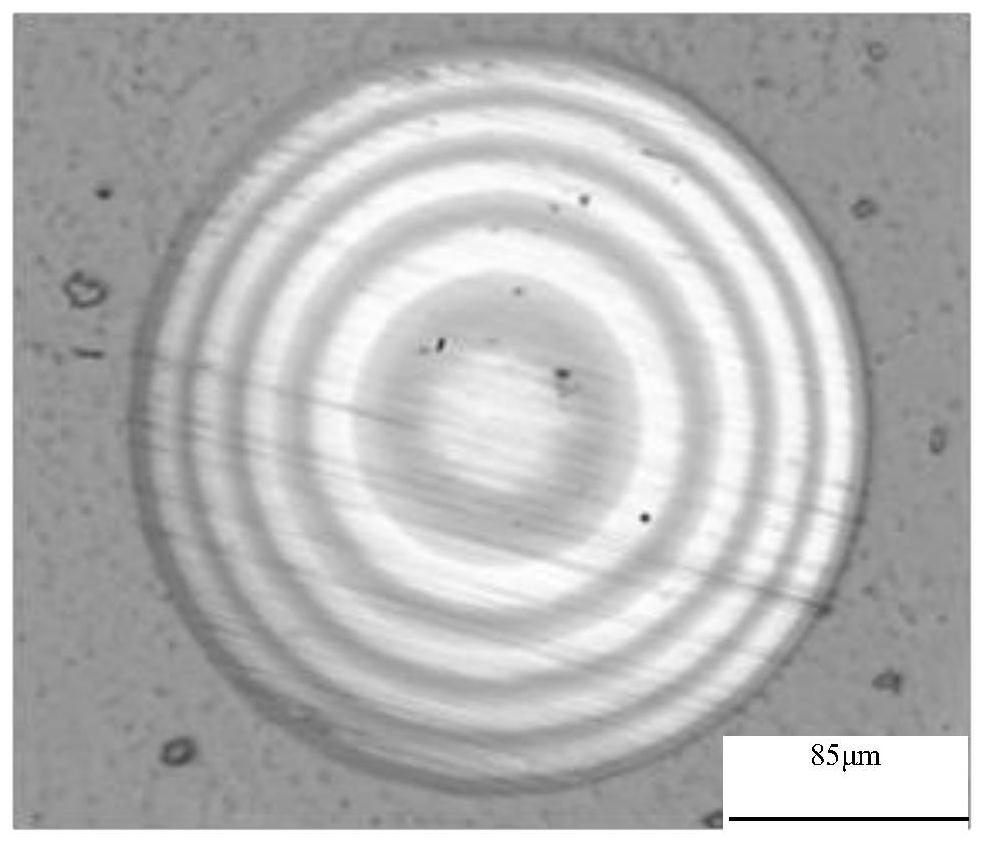

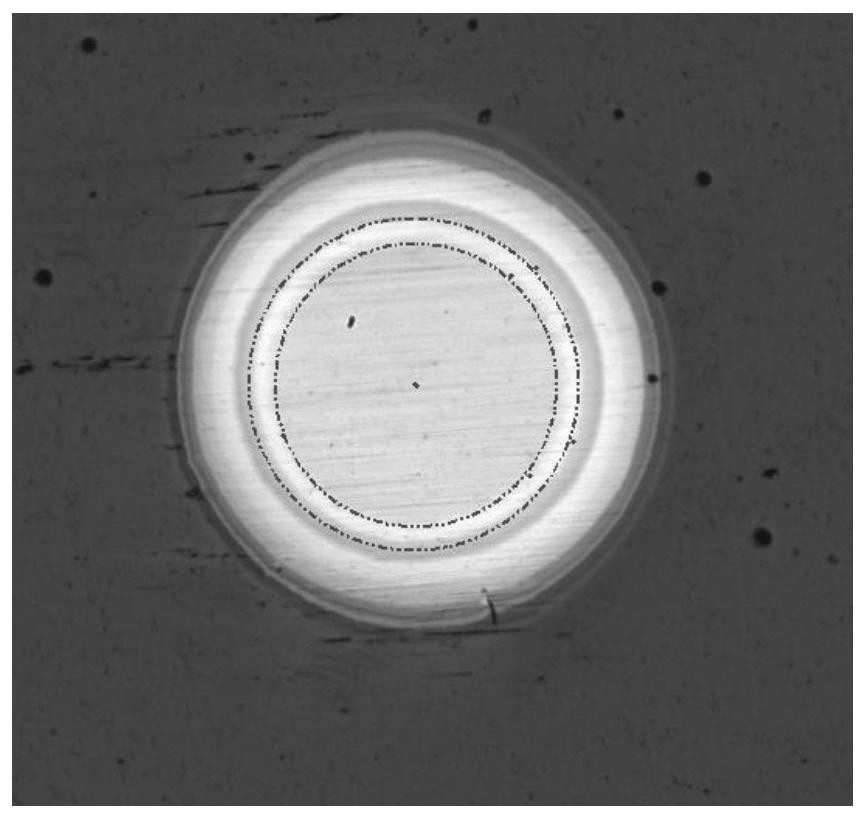

[0024] figure 1 The coating was rubbed with a ball pit instrument, and the multilayer coating morphology of the coating was observed under a microscope after rubbing. It can be seen that each layer is distinct, and the ring structure is basically a concentric ring, which is consistent with figure 2 Compared with the traditional coating preparation method, this process can prepare more layers of coatings, uniform layer thickness, and better interlayer bonding.

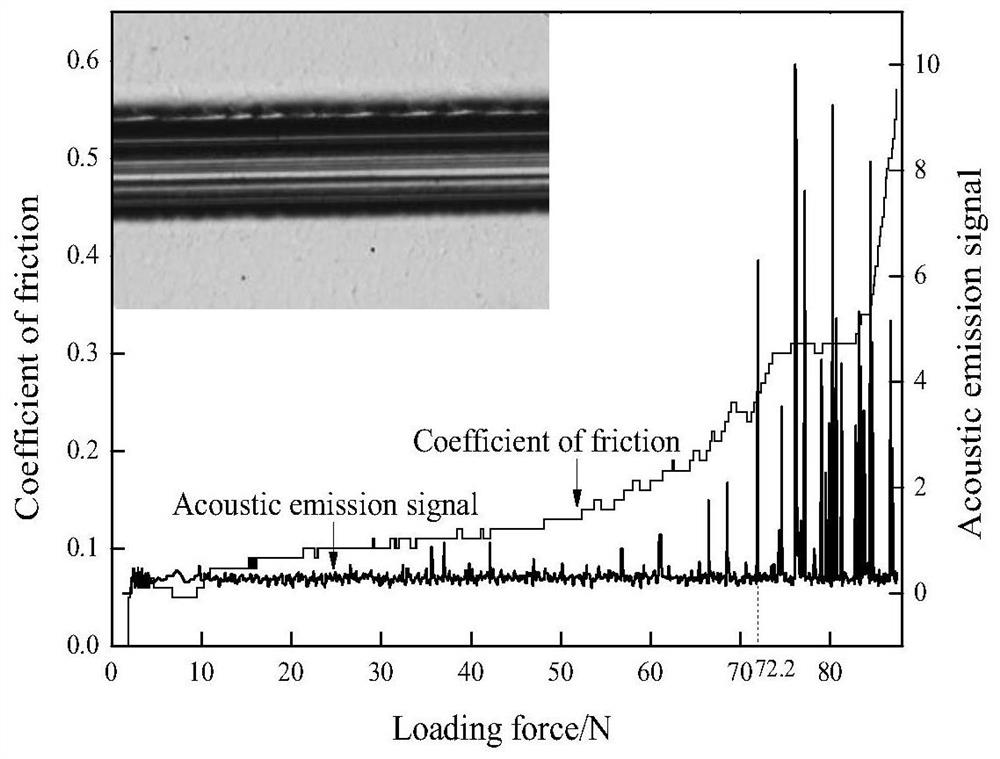

[0025] image 3 They are ARC CrN and (H+B)CrN respectively. The curves fluctuating up and down on the baseline in the figure are acoustic emission signal curves, and the trend line above the baseline is the friction coefficient curve. The sudden interval of the friction coefficient curve indicates that the diamond indenter scratches from the coating to the substrate. As shown in the figure, the critical load of ARC CrN is 33.5N, and the critical load of (H+B)CrN is 72.2N on the curve. The coating deposited by this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com