Nano twin crystal copper thin film material and preparation method and application thereof

A nano-twinned copper and nano-twin technology, applied in nanotechnology, nanotechnology, metal pattern materials, etc., can solve problems such as weak mechanical properties and inability to meet the requirements of mechanical service performance of copper interconnect materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

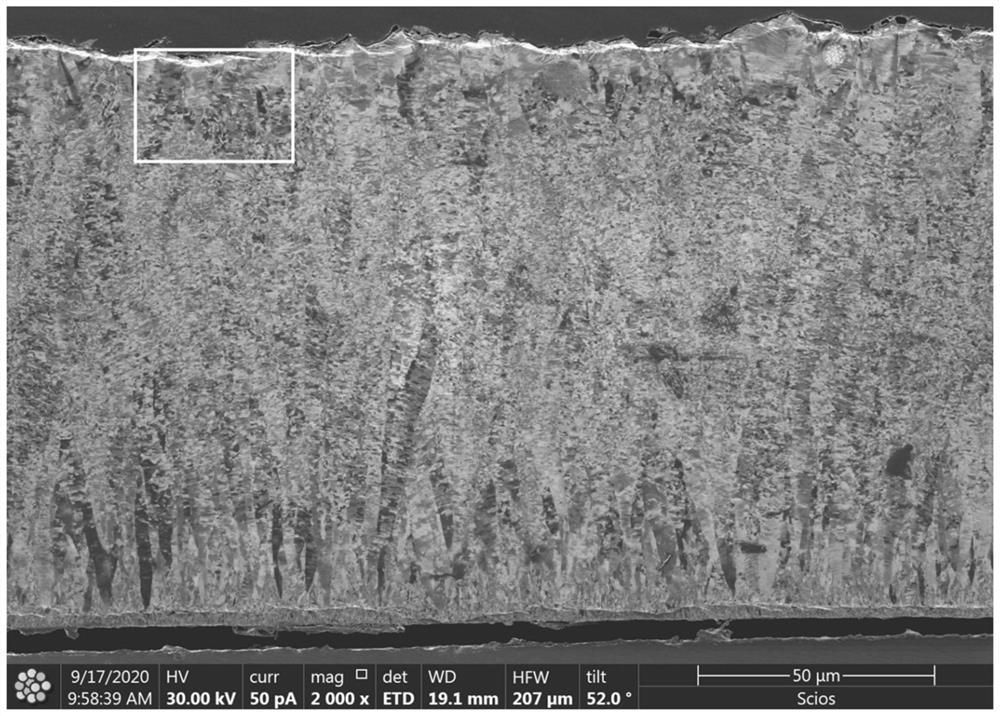

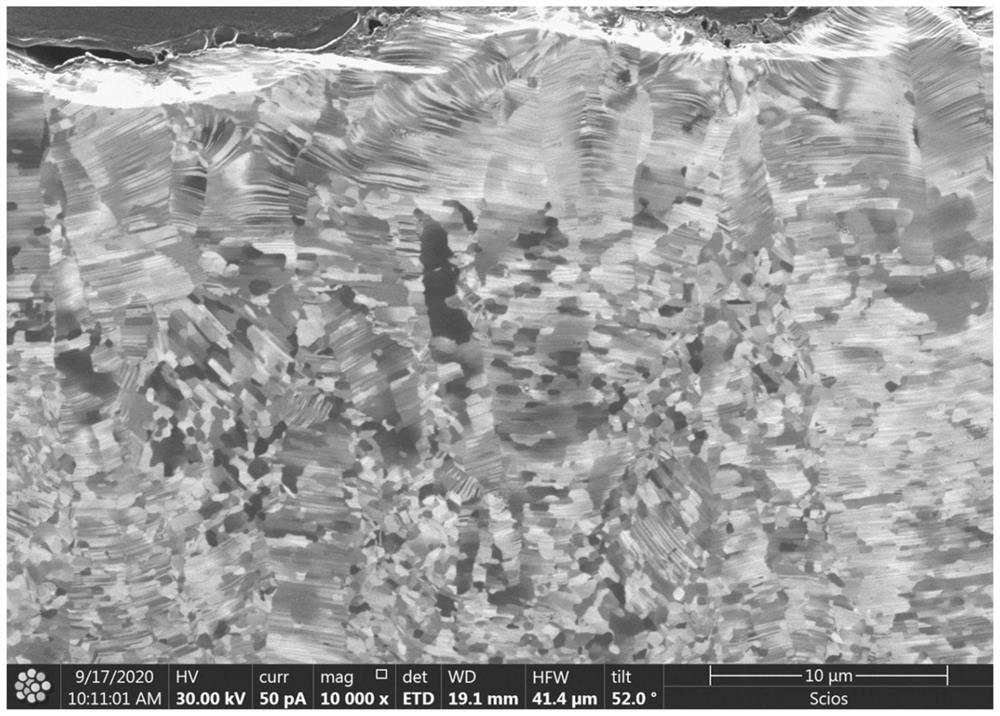

Embodiment 1

[0071] 1. Preparation of plating solution. The electroplating solution is prepared with the following component proportions and fully dispersed: copper ion 40g / L, sulfuric acid 40g / L, chloride ion 30ppm, accelerator 80ppm, auxiliary agent 20ppm, pure water 250mL;

[0072] Wherein, the accelerator is gelatin with a coagulation value of 100 bloom, and the adjuvant is sodium oleate.

[0073] 2. Cathode pretreatment. A high-purity titanium plate is used as the cathode, and it goes through the processes of degreasing, pickling, and water washing in sequence.

[0074] 3. DC electroplating. Immerse the titanium plate cathode and phosphor copper anode (phosphorus content 0.05wt.%) in the plating solution, apply 300rpm mechanical stirring and 700W 50Hz ultrasound, and control the temperature of the plating solution to 30°C. Then connect the rectifier to 4A / dm 2 Current density electroplating for 150min.

[0075] 4. Post-coating treatment. Take out the plating layer and substrate,...

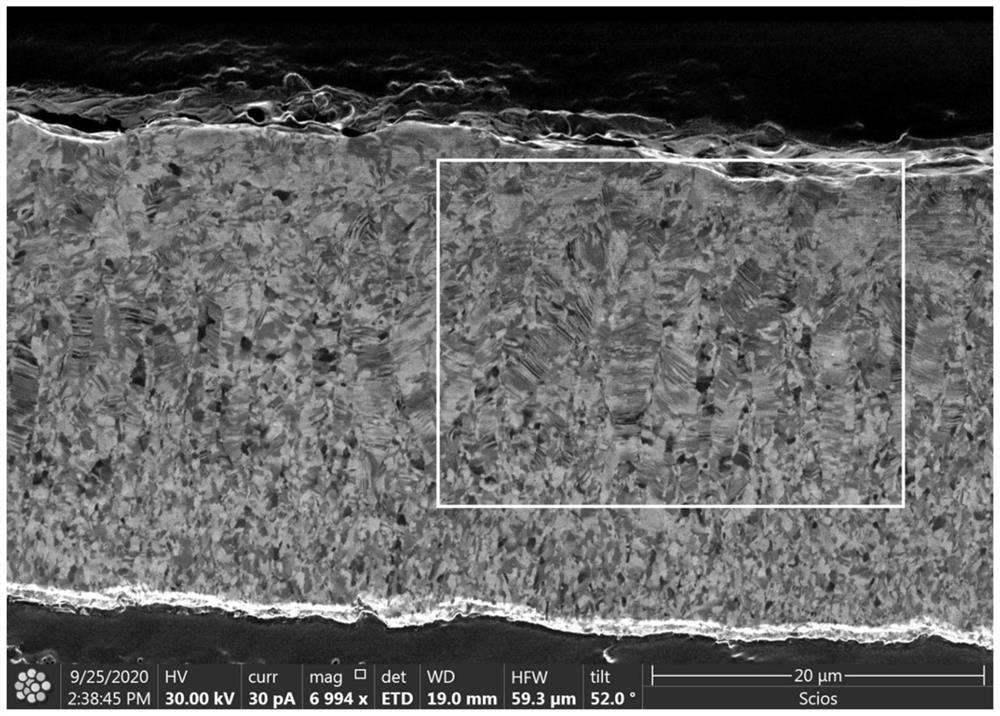

Embodiment 2

[0078] 1) Preparation of plating solution. The electroplating solution is prepared with the following component ratios and fully dispersed: copper ion 40g / L, sulfuric acid 20g / L, chloride ion 50ppm, accelerator 30ppm, auxiliary agent 10ppm, pure water 250mL;

[0079] Wherein, the accelerator is gelatin with a coagulation value of 80 bloom, and the adjuvant is sodium laurate.

[0080]2) Cathode pretreatment. A high-purity titanium plate is used as the cathode, and it goes through the processes of degreasing, pickling, and water washing in sequence.

[0081] 3) DC electroplating. Immerse the titanium plate cathode and phosphor copper anode (phosphorus content 0.05wt.%) in the plating solution, apply 300rpm magnetic stirring and 300W 50Hz ultrasound, and control the temperature of the plating solution to 25°C. Then connect the rectifier to 3A / dm 2 Electroplating at current density for 20 min.

[0082] 4) Post-coating treatment. Take out the plating layer and substrate, rins...

Embodiment 3

[0085] The difference from Example 1 is that 300 rpm mechanical stirring was not applied in step 3, but a 2 L / min circulating jet was used instead. The structure of the coating, the proportion of nano-twinned columnar crystals and nano-twinned equiaxed crystals are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com