Methyl vinyl silicone rubber and preparation method thereof

A technology of methyl vinyl silicon and vinyl fluorosilicone oil, applied in the field of methyl vinyl silicone rubber and its preparation, can solve the problems of reduced flexibility of fluororubber molecular chain, high oil resistance processing performance, poor processability and the like , to achieve the effect of improving crosslinking density, good processability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

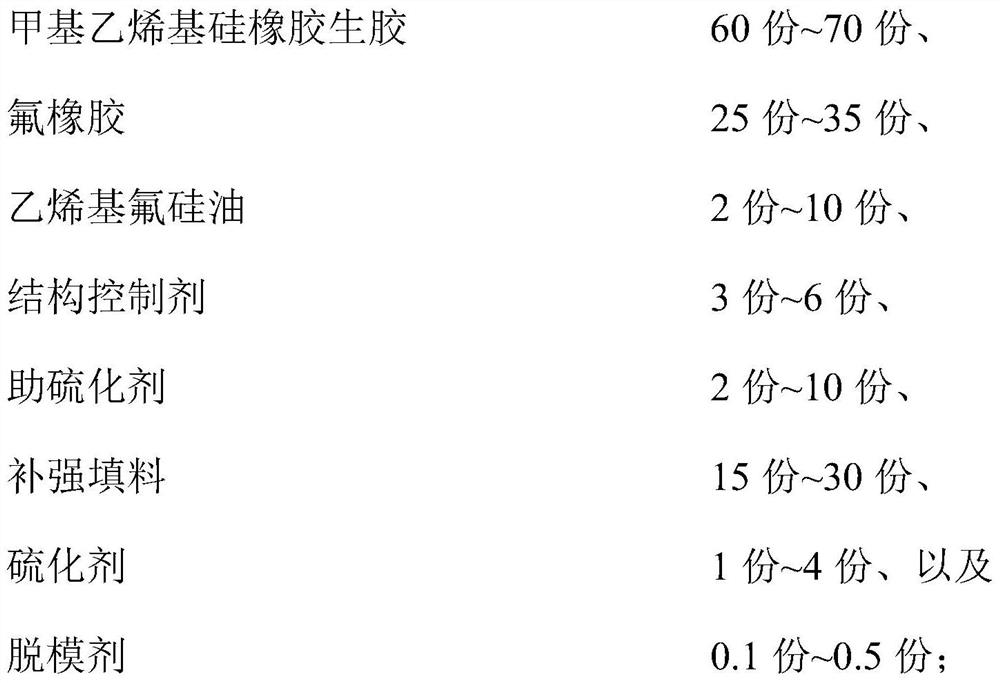

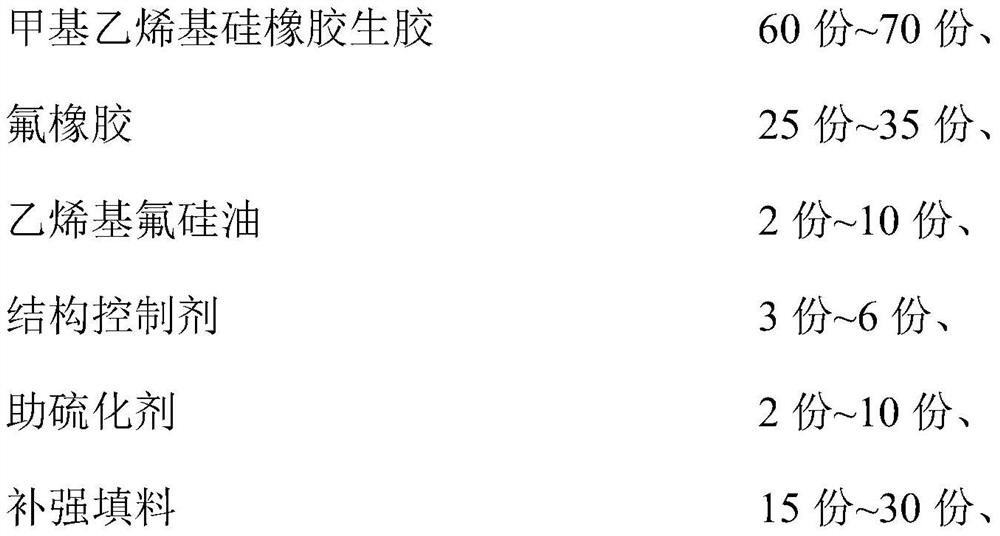

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides the preparation method of above-mentioned methyl vinyl silicone rubber, comprises the steps:

[0043] The methyl vinyl silicone rubber raw rubber, reinforcing filler, vinyl fluorosilicone oil, structure control agent and mold release agent are kneaded for the first time, and then the preheated fluororubber and auxiliary vulcanization agent are added. Secondary kneading to prepare mixed rubber;

[0044] Mixing the mixed rubber with the vulcanizing agent and performing a thinning treatment to prepare a mixed rubber film;

[0045] Extruding and vulcanizing the mixed rubber sheet.

[0046] The above-mentioned preparation method of methyl vinyl silicone rubber adds preheated fluororubber to the kneader in the last step of the silicone rubber mixing rubber production process, which can not only simplify the production steps, improve production efficiency, but also reduce the amount of fluororubber in the process. Fluorine loss in In one ...

Embodiment 1

[0053] The present embodiment is a kind of methyl vinyl silicone rubber, and its preparation method is as follows:

[0054] Preheat 30 parts of binary fluororubber (with a fluorine content of 66%) in an oven at 80°C for 2 hours. Add 19.5 parts of methyl vinyl silicone rubber raw rubber (vinyl mole fraction: 0.03%, average molecular weight: about 650,000), 45.5 parts of methyl vinyl silicone rubber raw rubber (vinyl mole fraction: 0.21%) into the kneader , average molecular weight: 680,000) and then add 4 parts of α, ω-dihydroxy polydimethylsiloxane (viscosity: 30mPa.s), 30 parts of precipitated silica (specific surface area: 200m 2 / g), 4 parts of vinyl-terminated fluorosilicone oil (70% fluorine content), 0.2 part of zinc stearate, kneaded at room temperature for 2 hours, fully kneaded evenly, then kneaded at 170 ° C and under normal pressure for 2 hours, and then Knead at 170°C for 2 hours at a vacuum of -0.08MPa, cool to 80°C, add 30 parts of binary fluororubber and 4 part...

Embodiment 2

[0057] The present embodiment is a kind of methyl vinyl silicone rubber, and its preparation method is as follows:

[0058] Preheat 30 parts of binary fluororubber (with a fluorine content of 66%) in an oven at 80°C for 2 hours. Add 19.5 parts of methyl vinyl silicone rubber raw rubber (vinyl mole fraction: 0.03%, average molecular weight: about 650,000), 45.5 parts of methyl vinyl silicone rubber raw rubber (vinyl mole fraction: 0.21%) into the kneader , average molecular weight: about 680,000) then add 4 parts of α, ω-dihydroxy polydimethylsiloxane (viscosity: 30mPa.s), 30 parts of precipitated silica (specific surface area: 200m2 / g), 6 1 part vinyl fluorosilicone oil (50% fluorine content), 0.2 part zinc stearate, kneaded at room temperature for 2 hours, fully kneaded evenly, then kneaded at 150°C for 2 hours at normal pressure, and then kneaded at 170°C under vacuum Knead for 2 hours at a temperature of -0.08MPa, cool to 80°C, add 30 parts of binary fluororubber and 4 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com