Preparation method of novel lignosulfonic acid/Nafion composite proton exchange membrane

A technology of lignosulfonic acid and proton exchange membranes, which is applied in the field of preparation of new lignosulfonic acid/Nafion composite proton exchange membranes, can solve the problems of high cost of proton exchange membranes, decreased mechanical properties, and environmental pollution, etc. Dense and stable, improved mechanical properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

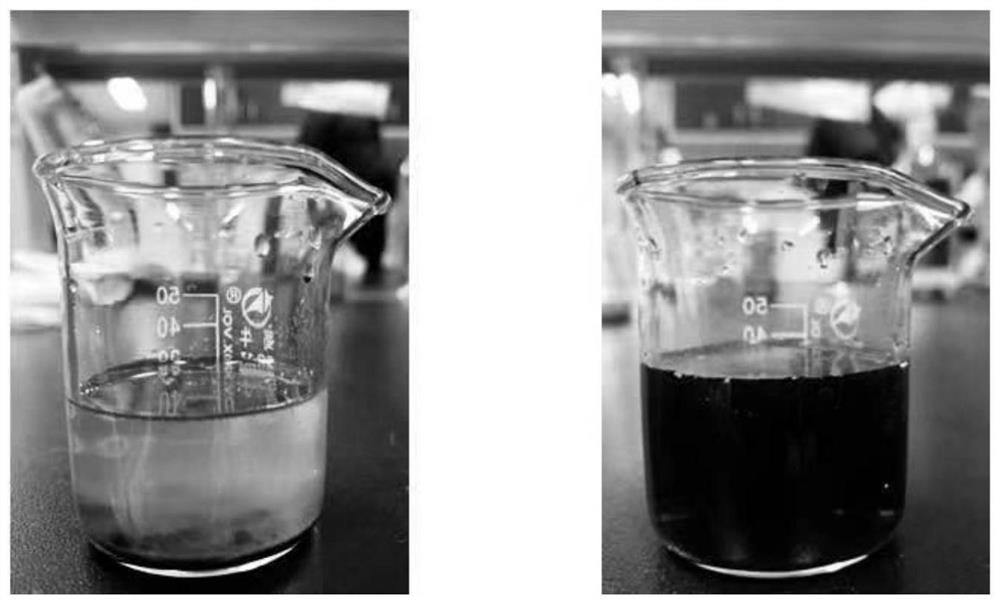

[0029] (1) Dissolve 10 g of sodium lignosulfonate powder in 40 mL of deionized water at room temperature, and stir well until no obvious solid matter exists in the solution;

[0030] (2) Slowly add the previously prepared 10% hydrochloric acid solution dropwise into the sodium lignosulfonate solution in step 1) until the pH is 2.0, continue to stir for 2 hours until the lignosulfonic acid is fully separated, centrifugally wash, freeze-dry for 24 hours to obtain lignin Sulfonic acid solid powder;

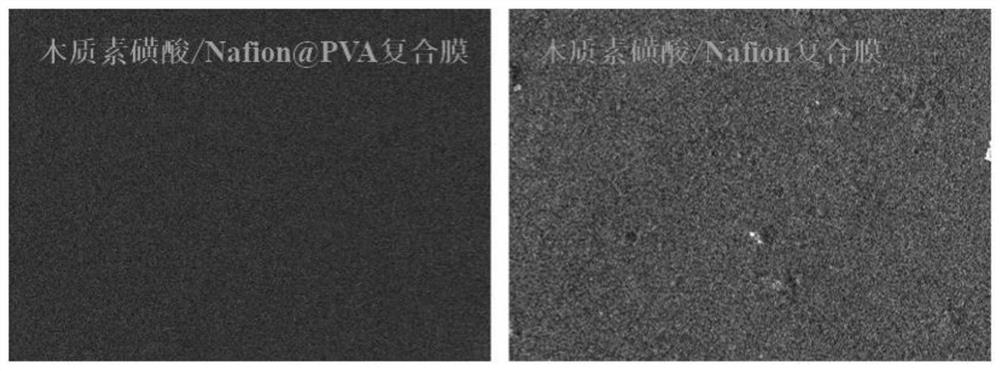

[0031] (3) Take 1.5mL of 20% Nafion dispersion in a clean small beaker, dry at 60°C for 12h to evaporate the solvent to obtain 370mg of solid Nafion resin, add 8mL of N,N-dimethylacetamide solution, and seal Dissolve evenly in a water bath at 60°C, then add 18.5mg of lignosulfonic acid and 370mg of 10% PVA solution, and continue stirring for 12 hours;

[0032] (4) Pour the homogeneous casting solution obtained in step (3) into a clean petri dish, place it horizontally in a vacuum dr...

Embodiment 2

[0034] (1) Dissolve 15g of sodium lignosulfonate powder in 50mL of deionized water at room temperature, and stir well until no obvious solid matter exists in the solution;

[0035] (2) Slowly add the previously prepared 10% hydrochloric acid solution dropwise into the sodium lignosulfonate solution in step 1) until the pH is 2.0, continue to stir for 2 hours until the lignosulfonic acid is fully separated, centrifugally wash, freeze-dry for 24 hours to obtain lignin Sulfonic acid solid powder;

[0036] (3) Take 1.5mL of 20% Nafion dispersion in a clean small beaker, dry at 60°C for 12h to evaporate the solvent to obtain 370mg of solid Nafion resin, add 8mL of N,N-dimethylacetamide solution, and seal Dissolve evenly in a water bath environment at 60°C, then add 55.5mg of lignosulfonic acid and 370mg of 10% PVA solution, and continue stirring for 12 hours;

[0037](4) Pour the homogeneous casting solution obtained in step (3) into a clean petri dish, place it horizontally in a ...

Embodiment 3

[0039] (1) Dissolve 15g of sodium lignosulfonate powder in 50mL of deionized water at room temperature, and stir well until no obvious solid matter exists in the solution;

[0040] (2) Slowly add the previously prepared 10% hydrochloric acid solution dropwise into the sodium lignosulfonate solution in step 1) until the pH is 2.0, continue to stir for 2 hours until the lignosulfonic acid is fully separated, centrifugally wash, freeze-dry for 24 hours to obtain lignin Sulfonic acid solid powder;

[0041] (3) Take 1.5mL of 20% Nafion dispersion in a clean small beaker, dry at 60°C for 12h to evaporate the solvent to obtain 370mg of solid Nafion resin, add 8mL of N,N-dimethylacetamide solution, and seal Dissolve evenly in a water bath at 60°C, then add 37mg of lignosulfonic acid and 370mg of 10% PVA solution, and continue stirring for 12 hours;

[0042] (4) Pour the homogeneous casting solution obtained in step (3) into a clean petri dish, place it horizontally in a vacuum drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com