Magnetic response color-changing photonic crystal ink for 3D printing and preparation method thereof

A photonic crystal and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of weak mechanical properties of hydrogel fibers, loss of reflectivity, unfavorable practical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

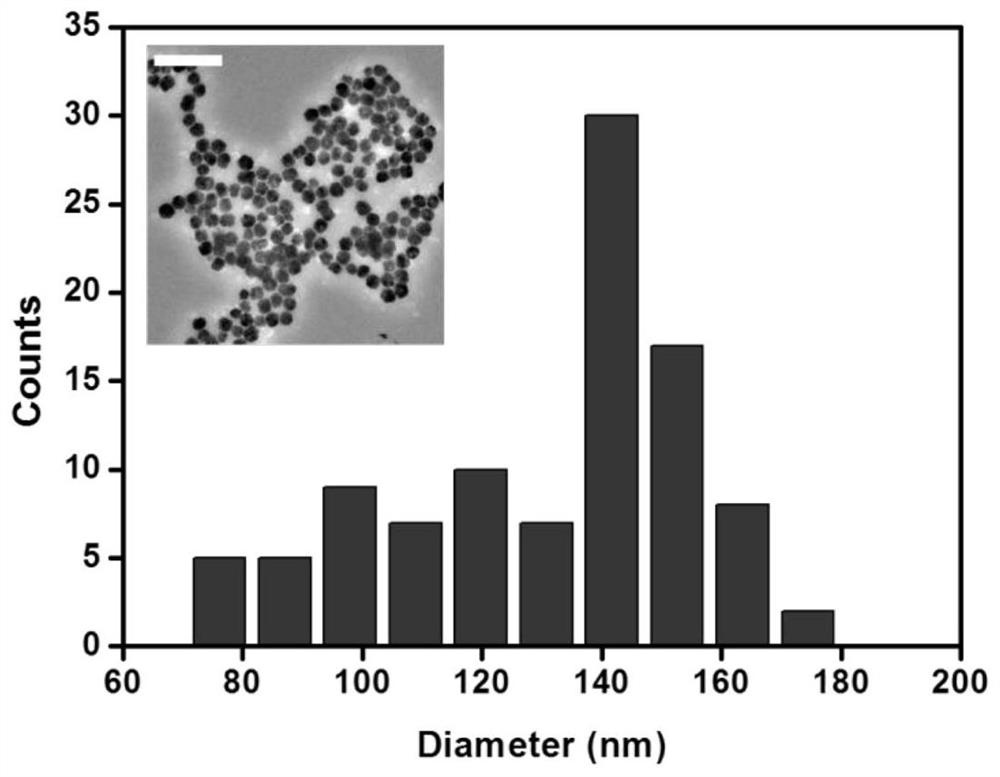

[0030] Embodiment 1, synthesizing monodisperse ferroferric oxide magnetic nanocluster

[0031]Measure 40 ml of anhydrous ethylene glycol into a 150 mL Erlenmeyer flask, and add 0.65 g of anhydrous ferric chloride, 3 g of anhydrous sodium acetate, 1.5 g of poly(4-styrenesulfonic acid-copolymerization-malay Acid) sodium salt (PSSMA) and 400 μL of distilled water were fully dispersed into a homogeneous solution by ultrasonication, stirring or heating, then 0.6 g of sodium hydroxide was added, and stirring was continued for 1 hour to dissolve. The above solution was transferred to a 50 ml polytetrafluoroethylene liner, sealed in a stainless steel reaction kettle, and placed in a constant temperature oven at 190°C for a heating reaction for 9 hours. After the reaction, it is separated by magnetic adsorption, and the product is washed with ethanol two to three times, and finally the product is dispersed in 15 ml of distilled water, which is the aqueous dispersion of ferric iron tetr...

Embodiment 2

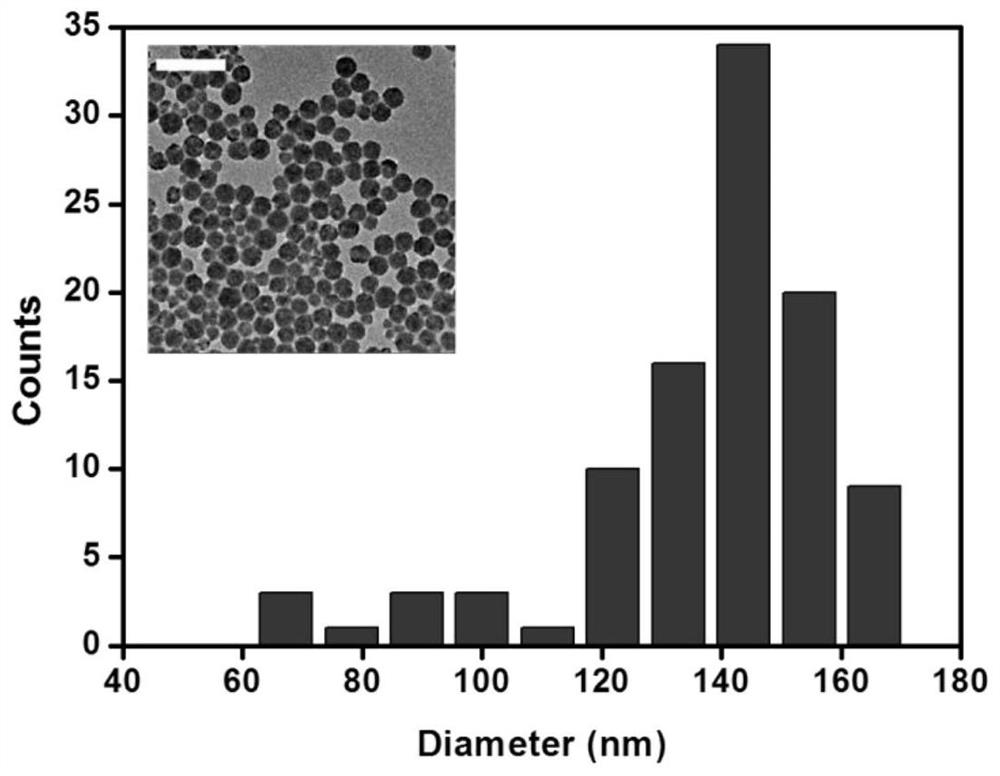

[0032] Example 2, Synthesis of Monodisperse Ferroferric Oxide Magnetic Nanoclusters

[0033] Measure 40 ml of anhydrous ethylene glycol into a 150 mL Erlenmeyer flask, and add 0.65 g of anhydrous ferric chloride, 3 g of anhydrous sodium acetate, 1.5 g of poly(4-styrenesulfonic acid-copolymerization-malay Acid) sodium salt (PSSMA) and 300 μL of distilled water were fully dispersed into a homogeneous solution by ultrasonication, stirring or heating, then 0.6 g of sodium hydroxide was added, and stirring was continued for 1 hour to dissolve. The above solution was transferred to a 50 ml polytetrafluoroethylene liner, sealed in a stainless steel reaction kettle, and placed in a constant temperature oven at 190°C for a heating reaction for 9 hours. After the reaction, it was separated by magnetic adsorption, and the product was washed with ethanol two to three times, and finally the product was dispersed into 15 ml of distilled water, which was the aqueous dispersion of ferric iron...

Embodiment 3

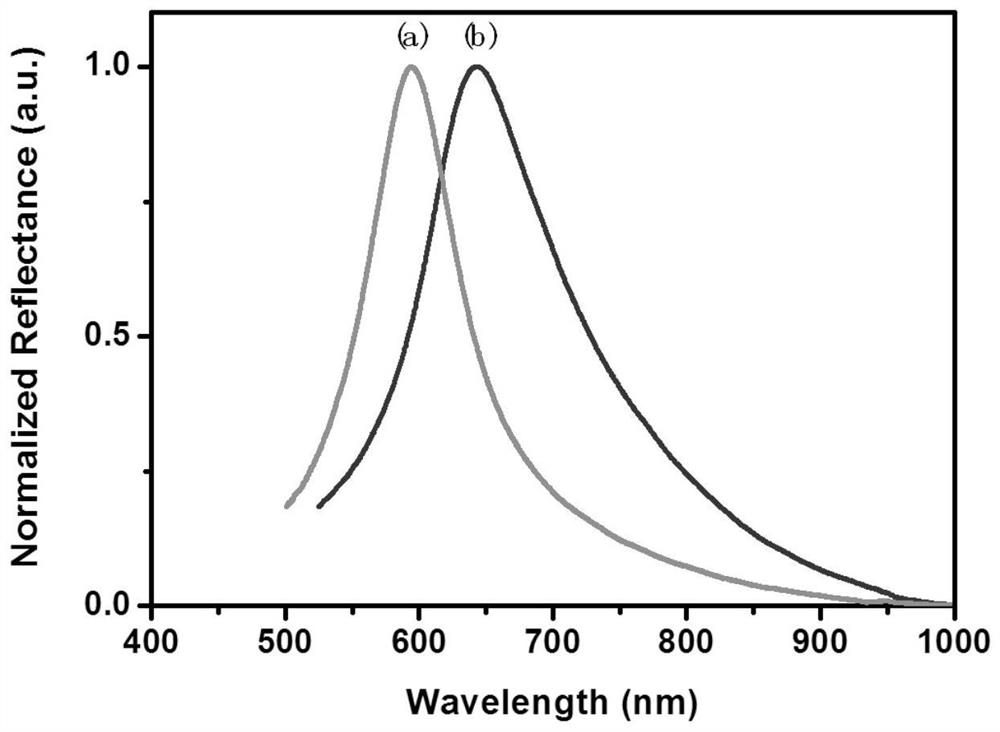

[0034] Example 3, preparation of photonic crystal ink with magnetic response color change

[0035] Take 1ml of the above-mentioned aqueous dispersion of ferroferric oxide magnetic nanoclusters (Example 1), separate by strong magnetic adsorption, absorb the water, and re-disperse in 1ml of ethylene glycol by ultrasonic. The silicone rubber precursor was obtained by stirring and mixing with polydimethylsiloxane (PDMS) prepolymer 2 g and crosslinker 0.2 g. Add 2 drops (about 0.04 g) of ethoxylated silicone surfactant and 1 ml of the ethylene glycol dispersion to the precursor, stir well until the mixture is emulsified to a viscous state, and put 0.15 g of hydrophobic fumed nano-silica Fully mixed with the emulsion, it is the photonic crystal ink with magnetic response color change. The ink can exhibit structural colors similar to its aqueous dispersion under a magnetic field, and can be directly loaded into the barrel of a commercial 3D printer for extrusion printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com