Cerium-zirconium-based composite oxide, preparation method thereof and loaded automobile exhaust purification catalyst

A composite oxide and oxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, zirconium compounds, etc., can solve the problem of difficult to achieve high specific surface area and Pyrochlore structure, difficult to make full use of the promotion effect and other problems, to achieve the effect of outstanding OSC performance, conducive to large-scale industrial production, high oxygen storage/release capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051](1) Preparation CEO2-ZRO2-Y2O3-LA2O3Tethery composite oxide, press 40% by% CEO2, 50WT% Zro25WT% Y2O35WT% la2O3The mass composition, weigh the nitrate, lanthanum, and yttrium, as well as carbonate, oxycarbonate, and oxycarbonate is dissolved using a certain amount of concentrated nitric acid.

[0052](2) The four salt solutions were mixed to obtain a mixed salt solution, and the moles of hydrogen peroxide was added to the mixed salt solution of 1.5 times the hydrogen oxygen, stirred well. The mixed solution of ammonia water and ammonium carbonate is a precipitating agent, and the mixed salt solution is simultaneously dripped into the stirred tank, and the pH of the system during the titration process is 8.8 to 9.0 to obtain a precipitated suspension.

[0053](3) The resulting suspension was branched at a 98 ° C water bath and an air atmosphere. Then, then add a target oxide product (initial cerium zirconium composite oxide) from the aging precipitation suspension to the lauric acid, ...

Embodiment 2

[0058]Preparation of CEOs as in Example 12-ZRO2-Y2O3-LA2O3The quaternary composite oxide, in addition to the hydrogen atmosphere treatment temperature of 950 ° C, using the same method as in Example 1 to obtain CEO with a green stone structure2-ZRO2-Y2O3-LA2O3Tethery composite oxide.

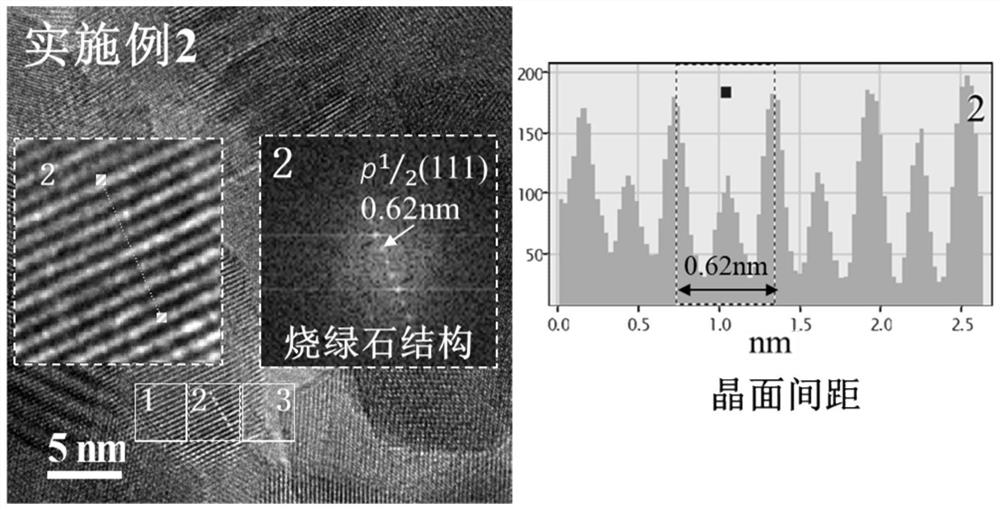

[0059]figure 1 CEO2-ZRO2-Y2O3-LA2O3HRTEM map of tetil composite oxide, 1 / 2 (111) Electronic diffraction of electron diffraction is 0.62 nm as a characteristic of a green stone structure, indicating a burning green stone structure. The resulting compound oxide BET specific surface area is 47m2 / g (Table 1), the CEO with high ratio surface area and green stone structure is obtained2-ZRO2-Y2O3-LA2O3Tethery composite oxide.

[0060]In order to characterize the above initial CEO2-ZRO2-Y2O3-LA2O3The thermal stability of the quaternary composite oxide will be 5 vol% O2 / N2The atmosphere was calcined at 1000 ° C for 4 h after 4 h, and its BET specific surface area, and the results showed 5 vol% O.2 / N2The composite...

Embodiment 3

[0067]Preparation of CEOs as in Example 12-ZRO2-Y2O3-LA2O3The quaternary composite oxide, in addition to the hydrogen atmosphere treatment temperature of 1000 ° C, the same method as in Example 1 is used to obtain a CEO with a burn green stone structure.2-ZRO2-Y2O3-LA2O3Tethery composite oxide.

[0068]According to the method in Example 1, the corresponding single palladium catalyst was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com